What is the difference between engineering and floorboard?

There are differences between the floorboard and its engineering counterpart. Outwardly, these two types of floor coverings are similar to each other, but they have different technical parameters and performance characteristics. In order not to make a mistake in choosing, before buying a floor covering you need to study its qualities, advantages and disadvantages, and then go to the store.

Features of the floorboard

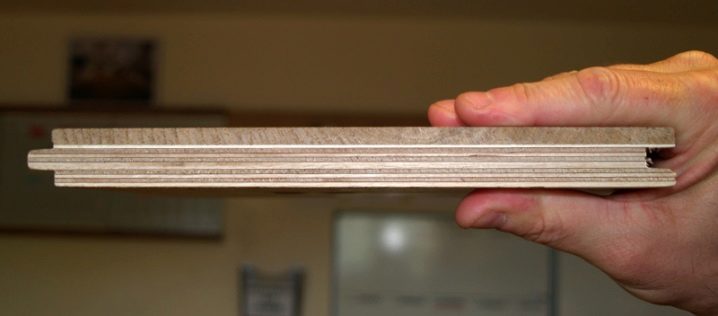

This flooring is a laminate for finishing the floor. It consists of several layers.

- Lower. The stabilizing basis made of a tree of coniferous breeds. The thickness of this layer usually does not exceed 1.5 mm. The fineness of the base makes the material easy.

- Average. Made of spliced technical wood. Thickness ranges from 6 to 9 mm. On this layer, cutting of tongue-and-groove locks takes place, thanks to which a strong “grip” of the slats among themselves is possible without the need for adjusting and polishing them.

- Decorative top. It is made from valuable tree species (oak, ash, maple). Visually, it is a thin lamella (1-4 mm). The top layer can be tinted with varnish, impregnated with oils, brushed, whitened, or otherwise treated.

In order to protect the thin face lamella manufacturers carry out multi-layer varnish.

Thus, a layer is formed on the surface of the finishing material, which protects it from mechanical effects and prolongs the service life.

Floorboard: the pros and cons

Parquet board - one of the most popular materials for lining the floor surface. This is a natural product with an aesthetic appearance and excellent performance. Other advantages of this material include such.

- Easy installation. On each plate there is a lock connection, with the help of which the products are securely fastened to each other. After laying the builders do not have to expose the coating grinding, grazing, or other types of treatments.

- Environmental friendliness. The material is made of wood without the use of harmful compounds.

- The possibility of dismantling the laid panels and their installation to another place without affecting their quality.

- Resistance to temperature changes in the room.

- Extensive range of products, featuring texture, color and type of processing.

- Relatively low price. The material can not be called cheap, but its cost is lower than the price of parquet.

Not without flooring and flaws. These include the "fear" of excessive power loads and humidity.

Sometimes the moisture resistance of the panels can be improved with the help of specialized additional processing of products.

Engineering board features

Engineered board - flooring material, consisting of two layers (plywood and veneer). The product has the following structure:

- bottom layer - base. It is made of waterproof plywood made of birch. The thickness of the base reaches 10-14 mm. The perimeter of the base is equipped with faces that form the lock.

- Top face layer. The decorative surface is made of expensive tree species, the cross section of which does not exceed 6.5 mm. This may be oak, ash, cherry and other breeds that are distinguished by high hardness.The decorative layer of the product is treated with varnish, oil or wax, thanks to which the tree acquires additional protection against moisture, dirt, mechanical loads.

Advantages and disadvantages of "engineer"

Engineering board is an elegant, durable, durable and geometrically stable material. The latter quality is especially important. Due to the unique design, this flooring is not deformed when the temperature in the room changes or when the humidity levels increase. The next important plus - excellent insulation. Due to such operational quality, the engineering board is often chosen by the owners of apartments in new buildings with good audibility. When using a highly elastic adhesive composition, it is possible to “absorb” the floor when laying the panels.

If the type of flooring is boring, it can be easily updated without resorting to complex technologies and expensive materials. If necessary, the engineering board can be scraped or ground, changing the appearance of the parquet. Thanks to the enlarged upper layer, the product withstands up to 7 regrinding.There is no finishing material, which would have no flaws. An exception was not the engineering board.

Its disadvantages include high cost, the inability to install an infrared heating system, complex installation, requiring appropriate knowledge and skills.

Similarities of materials

Comparing the engineering and floorboard, you can see a similar appearance of their decorative slats. The front layer of these two floor materials is made from the same raw material, which causes a visual similarity of products. In addition, the similarity of coatings is as follows:

- The presence of several layers in the design.

- Fixing products in a single coating with the help of locking connections.

- Installation on the floor surface as an adhesive method, and floating. Not so long ago, engineering boards were laid only with the help of glue, since they were equipped with a thorn-groove system. Today, due to the castle connections, they can be laid in the same way as parquet boards.

- Harmless to human and animal health. Both products are environmentally friendly, so you can safely lay them in the nursery or bedroom.

- UV resistant. Engineering and floorboard do not fade even with prolonged exposure to the sun.

- Poor water tolerance. If liquid enters the surface of the materials, both products may burst. This indicates the detachment of the decorative layer from the base. When drying, the board does not return to the previous form, such as parquet.

- Both materials can be repaired several times.

To understand which of the two facings is better, you need to find out their differences.

What is the difference?

The differences between the two types of coatings are as follows.

- Dimensions. The maximum dimensions of an engineering board are larger than parquet. Also, the “engineer” has a thicker decorative layer, which allows for more grinding cycles.

- Engineered flooring is more resistant to high humidity.

- Engineering coatings last approximately twice as long as the floorboard.

- The floorboard can be laid only by the deck method. Engineering panels are applied in various ways: squares, herringbone, deck method.

- Engineering boards possess the best noise isolation, than parquet analogs.

- Parquet facing is less costly in financial terms.

The difference between the two facing materials is obvious. The floorboard is an affordable lining, but in size it loses engineering. The latter is characterized by a wealth of variations of performance and a longer service life, but its installation and restoration is more difficult than renovation of parquet lining. What to choose is everyone’s business.

If you want to protect yourself from buying low-quality material, read the tips on the choice of facing products.

How to choose: recommendations

It would seem that it is easy to choose the floor covering, you just have to decide on the color and size of the material. However, things are not so simple. Manufacturers produce engineering and parquet boards in a wide range. In the market, identical products from different companies are often found in appearance, differing significantly from each other in quality.

Tips on how to choose the lining, so that she and the eye pleased, and served for a long time, will help to choose high-quality products.

- First, determine the thickness of the product. Refuse to purchase thin material (thickness of 7-10 mm).The thicker the lining is, the more geometrically it is stable. Thin options are "afraid" of the slightest power effects. They are easily deformed and damaged. Already after 2-3 years of use, facing boards with a thickness of 7 mm may lose their aesthetics.

- If you choose a material with a decorative piece made of oak, give preference to brushed products. In the course of such processing, the lining acquires relief. Scuffing, scratches, dents and other traces of mechanical stress will not be visible on such a surface.

- Experts advise to opt for products with a system closure UniClinic and T-Lock. Such compounds are convenient for laying and practical.

- Pay attention to the type of wood from which the decorative lamella is made. The strongest products are made from oak, cherry or walnut.

- When choosing between the lacquer and oil coating should be aware that there is no significant difference between these compositions. They are practical, easy to maintain. The only difference is that the oil base needs additional treatment (once every 4-6 months, the floors must be covered with oil or mastic).

- Prefer products from trusted manufacturers. Buy lining in large building hypermarkets. So you can minimize the risks of acquiring a fake product.

It is also important to choose not only high-quality material, but also aesthetic.

When choosing the color of the lining should focus on the overall design of rooms, shades of furniture, walls and ceiling.

Examples in the interior

Parquet and engineering boards - facing materials, with which you can give elegance and rich appearance to any room. A solid range of products with an extensive range of color variations allows you to choose the optimal type of lining in tune to a specific interior. According to the rules, mounted plates will visually resemble parquet made of solid wood, but the performance of such a floor will be higher.

Parquet and engineering boards are suitable for any interior design. If the room is decorated in a classic style, pick up the panel of "calm" colors with red or light brown shades. They emphasize the severity and restraint of the interior:

For modern styles, you can stay on the boards of dark shades (American walnut, stained oak, wenge) or contrasting light (olive, ash, bleached wood). Popular solutions that can transform a room, focus on the brightness and expressiveness of space are popular. Such a goal can be achieved by combining different panels (light and dark colors).

Often, flooring lining manufacturers enclose instructions on how to properly lay out panel patterns. To get an original ornament, plan your work in advance, experiment with colors and shades.

You will learn more about the difference between engineering and floorboard in the following video.