Epoxy grout tile: the pros and cons

Epoxy grout (or epoxy) is a special aggregate that is used to fill the tile joints. It combines two main functions and performs both a decorative and protective role. On the peculiarities of such grout talk today.

Special features

The main difference between epoxy grout and standard cement mix is that It consists of two main components:

- Epoxy resin (+ silica filler + pigment + plasticizer to make it elastic).

- Special hardener.

It also differs from cement in that it is much more plastic, it can be of different colors and shades and sets itself up extremely quickly, the latter is often referred to as disadvantages rather than advantages.

Acquiring epoxy, you need to understand that it is significantly different from the usual composition based on cement.If, diluting the cement mixture, you can allow some errors in the proportions, then with epoxy it is by no means permissible. Working with a grout, two important rules are observed: the exact dosage of the proportions and the working time of the composition.

Therefore, starting to mix the composition, one cannot do without an electronic clock.

Some features that distinguish epoxy grout from cement:

- Epoxy grout has a hydrophobic property that provides full waterproofing seams. It provides a solid and stable color without any stains and abrupt transitions. Resistant to chemical reagents, especially to acids and alkalis.

- Not prone to rust, cracking and dirt settling. Resistant to fungi, ultraviolet and sudden temperature changes.

- It has a wide range of colors and additional decorative features, such as pearl, bronze, silver and metallic effects (glitter).

- It has a very long life. According to the promises of manufacturers, the grout can last up to 50 years without any external changes.

- This mixture can process the seams of tiles made from many materials.The tiles can be ceramic, porcelain, glass, marble, metal, clinker, porcelain stoneware, agglomerate, stone and wood. The size of the seam can vary from 1 to 15 mm.

- This mixture is excellent in those cases where material resistance to the aggressive chemical action of reagents is extremely important: swimming pool, garage, car wash, workshop, laboratory. No less effective is its use in the food industry.

- In residential buildings the structure is used in the following rooms: bathroom, balcony, terrace, corridor. It is used in the decoration of the kitchen apron or mosaic worktops, steps and even in the system of warm floor.

- A mixture of epoxy base can also act as a tile adhesive. She can attach a glass or metal mosaic laying, while the color of the seams and the adhesive itself will be exactly the same.

However, the grout has several significant drawbacks:

- High price. For work, you need not only a two-component grout, but also a solution designed to remove plaque. In the future, if you suddenly need to replace the defective element, you will have to buy the full volume of grout again, only to handle a pair of joints.

- Features in application. Such a mixture is not suitable for beginners, a person without work experience can easily spoil everything. In the end, the seams will come out rough, and on the tile itself there will be stains that are difficult to remove. All because of the epoxy resin, which can only be removed with the help of chemistry or by mechanical means. Once the grout has been applied, it is no longer possible to level it with a spatula, because of its great elasticity, this can only be done with a sponge and very carefully.

- Rough surface. The surface of the grout can be compared with sandpaper, because it contains sand. This somewhat complicates the process of cleaning the seam from various contaminants.

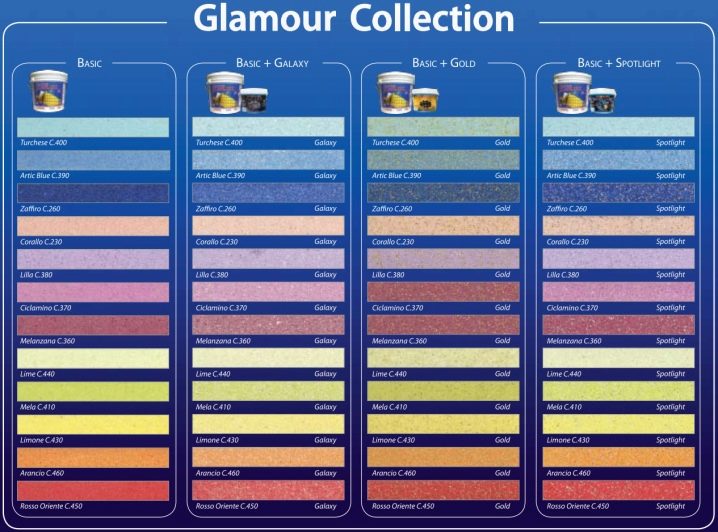

Colors

Of course, color plays an important role and is one of the main parameters when choosing a grout. It is provided by the general composition at once or by adding various pigments (dyes) during the kneading process, due to which the mixture can be black, white and any other shade. This is also achieved by adding colored quartz sand and additional brilliant components - glitters (for example, gold grout).

However, this diversity not only simplifies the design of the room, but also causes its own difficulties.If you can not find the desired shade, the manufacturer offers special dyes that are mixed with white grout.

There is also a completely transparent mixture that is perfect for working with glass stained glass.

Useful tips when choosing a grout by color:

- Beige and pastel epoxy visually combines each tile into one whole composition. But the dark color composition, on the contrary, is able to visually divide the wall into separate sections.

- For a tile that includes three or more colors at once, or with complex patterns, the composition is chosen according to the size of the working room or surface itself. If the room is small, then the mixture should correspond to the brightest tone, thus combining the whole picture. If the room is large, the grout, on the contrary, corresponds to the darkest color.

- For monochromatic ceramic tiles, the mixture should be selected based on the colors used in the interior design. Grout should create a contrast with the finish coating, but it does not stand out from the whole tile.

- If the facing tile is similar to a mosaic, then the mixture should be calm - beige or gray.

- If you can not choose a suitable color, you can use the standard white. However, if the floor tiles, white grout can not be applied, because over time it will lose its aesthetic appearance and will seem dirtyish-gray.

- The original solution is to choose a mix to match the elements of the furniture in the room, and not to match the tile.

It is worth remembering that the bathroom should not be used more than three different shades.

Usage tips

When buying a mixture, you must rely on the following indicators:

- The time it takes to dry.

- Resistance to chemicals.

- Shelf life.

- The volume of the package itself.

- Grout consumption per square meter.

- Sizes of seams.

It is possible to begin to process the seams only 24 hours after the direct installation. Pre-seams and tile surface must be cleaned of excess glue.

If the tile is a light color, some problems may occur. Sometimes at the place of trimming when there is a mixture of grout or any other liquid there, the edges darken. Therefore, 24 hours before work, it is necessary to check the reaction of the tile, and in case of darkening of the edges, to protect them with masking tape.

Necessary tools and means:

- Epoxy grout.

- Drill with mixer for mixing the working mixture.

- Capacity with water.

- Grater with a rubber sponge.

- Special cellulose sponge for removing grout.

- Spray bottle filled with water.

- Protective gloves.

- Mixing bucket (or basin).

- Libra.

- Any cleanser that is intended for epoxy.

Immediately from the suppliers, you can purchase special cellulose sponges or synthetic rags. The cost of sponges ranges from 500 to 600 rubles, while a rag costs about 150 rubles. Instead of a sponge, sometimes ordinary foam rubber is used. But he quickly deteriorates and strongly chooses grout.

How to breed?

The composition is sold in two packages (epoxy component and hardener), in which the substances are in the right proportion. To prepare the working of both packages, you just need to mix. However, the composition is efficient for no more than an hour, so it is better to independently calculate the required number of components using a scale, and prepare the right amount of the mixture. It is worth considering that each grout needs its own proportion, so before calculating it is necessary to read the instructions.

Additional substances, for example, a dye is added to the prepared mixture and mixed.

How to apply?

Instructions for applying epoxy grout with your own hands:

- We collect a small amount of the mixture on a spatula and grind on the surface. It is more convenient if two people work: the first one applies, the second one immediately blurs the grout.

- We moisten the sponge in a container with water and wash out the seams, the main thing is not to reach the end of the seam. This is done in order not to wet the still dry, untreated tile, as it must be dry.

- After cleaning the seams, we take a new sponge, wet it with water and form them until the end.

- Reapply a layer of grouting and perform the same manipulations.

- The hardest thing is to rub the inner corner. Therefore, it will be easier if you first treat one corner, and on the second day another.

- To get the perfect seams, after about 40 minutes, spray them with a spray gun and lightly smooth over with your finger.

- If the flooring has been finished, then it cannot be moved through it in the first couple of days, as some grouting can dry out within four days.

Finishing stage of cleaning:

- At the end of the grouting process remains a raid.But do not worry, it just enough is washed off.

- When painting works are done, the seams need to be closed with masking tape, otherwise they will deteriorate during paint washing.

- In order to remove plaque, we mix the cleaning agent for epoxy grout with water, following the instructions.

- Spray the solution on the wall and give it time to soak in, after wiping with a cloth with villi.

- Then wash off the formed foam. The self-squeezing mop will cope well with this.

- The final cleansing stage is carried out with a microfiber cloth.

- It is impossible to achieve complete removal of the grout, on the surface there will still remain a thin sticky plaque, similar to a plastic one. White tiles need to be cleaned for a longer time so that it does not eventually acquire a yellowish tint.

Manufacturers

Some of the most famous foreign and domestic producers:

- Litokol (Italy). The material is stored for two years at + 5 ° C. It is not allowed to lower the temperature, otherwise the components will become solid and lose all their properties. This manufacturer offers a grout of 103 colors, including various additional effects.Suitable for use both indoors and outdoors. The price ranges from the smallest (1 kg) - 1300 rubles, the average (2.5 kg) - 3500 rubles. up to the largest package (5 kg) - 4000 rub. Positive qualities of brand products:

- Lack of smell.

- Suitable for use in rooms with poor air ventilation.

- Easy to apply.

- High resistance to temperature changes and high humidity.

- Mapei Kerapoxy. The main difference between the products of this manufacturer is that the grout has a minimum grain. However, the range of products is limited: only 26 colors are presented. The manufacturer produces a three-component grout that is even more resistant to acids and other aggressive chemicals. The price of 3 kg - 3500 rub., 10 kg - 5600 rub.

- "Diamond" (Russia). Grout is presented in an assortment of 46 colors. But it can only be used for processing the bathroom. Sold in a package of 2.5 kg - from 2000 to 5000 rubles.

- "Founds." Epoxy grout of this company is characterized by high resistance to temperature changes (from - 50 to + 75 ° C), elasticity, hydrophobic property and is not predisposed to the development of fungus.Solution is suitable for work within an hour. The grout is available in 29 colors, the packing of 2.5 kg each is 2000 rubles. In general, has all the properties that are characteristic of epoxy.

- "Fugue". The product has all the properties characteristic of epoxy grout. Suitable for processing both indoors and for exterior decoration. The solution is usable for two hours. The material is presented in 32 colors. The cost varies considerably, for example, in online stores you can buy 2.5 kg of dry mix for literally 2,000 rubles, while in retail stores the product will be much more expensive.

Whichever company the buyer chooses when starting to work, it is necessary to familiarize yourself with the instructions on the package and act on it.

Reviews

Consumers prefer epoxy grout because of its high stability, long service life and wide range of applications. In addition, many argue that this mixture is ideal for porous tiles, since after it does not remain colored stains, which are often formed after the cement mixture. Epoxy is a godsend for designers who need a clear color selection and decorative effect.

Consumers point out that the grout does not depend on temperature and easily transfers drops from - 20 to 100 ° C. The composition does not shrink, and after drying it does not form cracks, like on a cement grout. Also emphasize the hypoallergenic material and its complete safety for the health of others.

The fastest way to grout joints, see the following video.