Cork compensator between tile and laminate: features of use

Installing a cork compensator between tile and laminate is a popular method for making joints between materials. Combining flooring helps to realize bold design ideas and increases the life of the floor in places of the most intense load. The compensator allows you to dock tiles with laminate without the use of thresholds, which makes it possible to obtain a smooth and uniform surface.

Benefits of Cork Compensator

The cork compensator is a sheet of pressed cork, which is easily cut with a sharp knife. The popularity and high consumer demand of the material are due to a number of positive properties.

- Full environmental safety compensator. The material is made of natural components, therefore it can be used in all types of residential and public spaces.

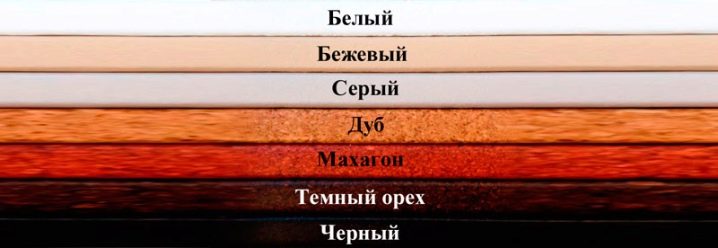

- Wide range of colors. The cork is excellent for dyeing in any color.With the help of special light-resistant colorings, it is possible to obtain a variety of surface color and tone.

- Easy assembly and disassembly of the material. To cope with the installation of the compensator will be able to anyone, even without experience in laying floors. This saves time and money when carrying out repairs.

- Excellent indicators of elasticity and elasticity. In comparison with rubber and silicone compensators, the cork is not subject to hardening. The unique property of a cork is its ability to always take on its original appearance. This allows it to compensate for the regular cycles of expansion and compression of the laminate and to maintain its performance throughout the life of the flooring.

- High quality material. Over time, the cork that has been pre-treated with varnish does not crumble or crack, which makes it possible not to fear for the integrity of the floor for many years.

- Low cost allows you to purchase cork compensator at a comfortable price for the buyer.

- Natural antiseptic properties of the cork, due to which the material is not susceptible to rotting and the appearance of mold and mildew.Cork is of no interest to insects and rodents.

- Cork compensator is resistant to ultraviolet radiation and is not prone to the accumulation of static electricity.

- Material during combustion does not emit phenol, chlorine, cyanides and other similar toxic substances. After treatment with a special compound, the compensator complies with safety class G1 (non-combustible substances).

Kinds

Cork compensator is available in liquid and solid form.

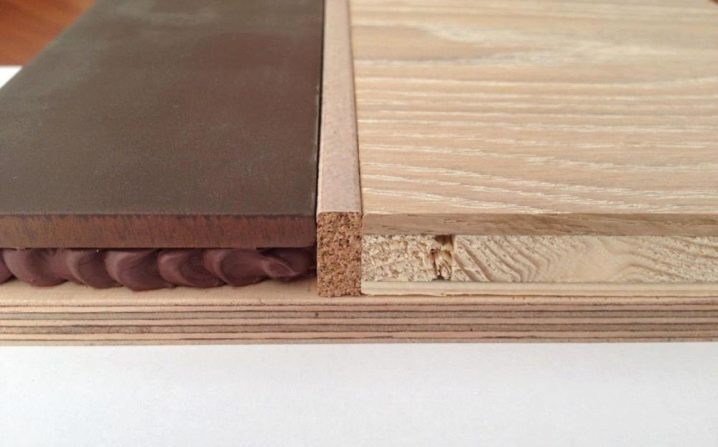

The solid form of release is represented by sheet material having a length of from 90 cm to 3 m, a width of up to 10 cm and a thickness of from 15 to 22 mm. The material can be painted in any color and coated with 7-10 layers of polyurethane varnish. Cork is indispensable when making joining between tiles and laminate. The material is cut in the form of narrow thresholds, which are mounted in the joint between the flooring.

For the manufacture of solid species, the bark of cork oak is used, pressed in special heat chambers without the use of glue and other chemical components. Liquid form is a mixture of elastic cork mass, adhesive and solvent. Available in sealed containers with a capacity of 500 ml.

The air-filled cells of the cork granulant endow the material with high heat and sound insulation properties, thus providing protection against external sounds with a capacity of up to 27 dB. The liquid compensator is highly resistant to high and low temperatures, does not shrink and does not exfoliate when exposed to weight and mechanical loads.

The density of cork sealant is 0.34 g / cm, and the final hardening time is from 6 to 12 hours. The material is applied with a spatula or air pistol.

The moisture limit for the surfaces being trimmed is 3%.

The disadvantage of this type of compensator is the need for quick installation, due to the very high speed setting of the material.

Installation Features

There are strict requirements for the transition between laminate and tile. Achieving a positive result will help strict adherence to installation technology and accuracy in execution. The main requirement for joining surfaces is the absence of flaws at the edges of tiles and laminate..

If tile laying is carried out with the cut side to the joint,then its edges must be carefully polished, and the edge of the laminate is treated with a special composition that protects the material from moisture.

In addition to tile, laminate and compensator, you need to purchase wood glue and sealant, which will be needed to conceal minor bending defects at the joint. The color of the veneered end of the compensator is selected in accordance with the overall color scheme of the floor covering.

Installation of a solid cork compensator is performed when one type of coating has already been laid. The first step is to trim the height of the cork tape. This should be done with a sharp knife, previously delineated on the strip the place of the cut. It is better to glue the compensator to glue for wood, after having previously cleaned and degreased the installation site. The mounting algorithm of the compensator is as follows:

- thorough preparation of the joint by cleaning from mechanical debris, dust removal and priming;

- applying a thin strip of glue near the edge of the slats;

- laying the compensator tape on the applied glue and fixing the end edge;

- applying a sealant between the edges of the laminate and the compensator;

- removal of excess sealant with a wet cloth, followed by wiping the joint dry.

Further installation of tiles produced from the formed joint. This will ensure a tighter fit of cork and ceramics. After the installation and the complete drying of the sealant and glue, the cork joint, which does not have a veneered edge, is ground and varnished.

Installation of a liquid cork compensator should begin with a masking tape adhesive tape on all edges of already laid surfaces. The joint is cleaned of mechanical debris and dedusted. Works should be carried out at air temperature not lower than 5 degrees. The installation of a liquid cork commutator consists of the following steps:

- pour the composition of the tube into a wide container;

- fill the seam with a spatula or an air gun;

- cut off the excess seal with a spatula;

- wait until the surface is completely dry, which depends on the thickness of the connector, the width of the joint and the temperature and is 24-48 hours;

- remove the masking tape and wipe off residual sealant from the floor.

It is very easy to mount the liquid tube. The only drawback of installation is the need for accurate and even distribution of the composition at the stageapplication, so as to correct the defects of application and align the seam after drying the material is no longer possible.

The cork compensator between tile and laminate will allow you to achieve the perfect combination of two surfaces and make the floor spectacular and tidy.

The whole process of installing the cork compensator can be viewed in the next video.