Ceresit tile adhesive: specifications and consumption

Ceresit tile adhesive, produced by the company of the same name, is considered to be one of the best linings available on the European market. The products are manufactured on high-tech equipment of the German concern Henkel and meets the highest requirements for manufacturers of building and finishing materials.

Benefits

High consumer demand and the growing popularity of glue are due to a number of positive product qualities:

- High elasticity and excellent resistance to deformation do not allow the adhesive layer to crack or sag. Under the influence of weight and mechanical loads, the solution does not lose its original shape and prevents the tile from “slipping”.

- Good adhesion composition provides a strong grip with a rough base, and with the tile laid on it.Glue can be applied on any bases, including gypsum cardboard and wood-shaving plates. Due to the high bonding properties of the composition well retains both standard and large in size plate, which is very convenient when forming a combination of surfaces consisting of plates of different sizes. The structure is convenient for work on vertical surfaces.

- Increased moisture and frost resistance allow you to use the adhesive solution for outdoor work in any climatic conditions. The solution can be used when installing tiles in a pool bowl and is well suited for installing a “warm floor” system in it.

- Full environmental safety the material is due to the absence in its composition of toxic and toxic components, which eliminates the formation of harmful fumes under the influence of high temperatures. This property allows the use of glue in the baths, saunas and bathrooms.

Technical features

Ceresit glue is intended for installation of ceramic, clinker, ceramic-granite and stone facing materials with moisture absorption values not exceeding 3%. When pouring a screed for the “warm floor” system, it is recommended to add a liquid elasticator to the composition. This will protect the adhesive layer from the appearance of cracks during regular expansion-compression cycles, which inevitably occur under the influence of different temperatures. To operate the adhesive composition can be at a temperature of from -50 to 70 degrees. Cold resistant compounds can withstand up to one hundred cycles of freezing and thawing without compromising their working properties.

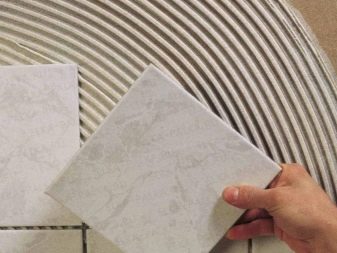

The adhesive mixture is a dry powder composition that requires self-preparation. The amount of water that the glue is diluted corresponds to nine liters per standard bag weighing 25 kg. The time for a possible correction of the position of the tile is 20 minutes, after which the solution “seizes”. Then it will no longer be possible to correct stacking defects. After preparation, the mixture retains its operational properties for three hours.

The dry mixture contains cement, and as a result of its interaction with water, alkaline reactions occur. This circumstance requires strict adherence to individual protection measures when working with glue, which consists in the use of glasses and gloves.

Work with the adhesive composition is recommended in the temperature range from 5 to 30 degrees and relative humidity not exceeding 80%.

The release of the adhesive mixture is carried out in multilayer bags of paper weighing from 5 to 25 kg. The cost of glue varies from 250 to 300 rubles per bag weighing 25 kg and depends on the brand of composition. Glue is produced in two modifications: with reduced dust formation and in standard form.

Application area

Ceresit tile adhesive is designed to work with all types of finishing materials, except marble slabs. The basis for the installation are any materials, including gypsum fiber board, PVC, OSB, fibreboard and other bases prone to deformation. Use of glue on plaster and old facings is allowed. Mix is used for finishing of facades, a socle, entrance groups, parapets, terraces and balconies. Glue can be successfully used for finishing a subfloor consisting of young and cellular concrete.

Paint coatings that have not been peeled off can also act as a rough base. The material is well suited for the installation of rigid and elastic coatings made of materials CR-65, CL-51 and CR-166.

Kinds

Ceresit tile adhesive is available in a wide range.

The model range is represented by several brands, which differ in technical parameters and operational properties:

- Ceresit SM-9. The composition is considered the weakest of all mixtures. It has low frost resistance and is not intended for work in unheated premises and on the street. Glue has a cement base and is used for laying decorative bricks, small-format tile types and artificial stone. Full hardening time is three days. The adhesive can withstand about thirty freeze-thaw cycles and is used for stable concrete and cement foundations.

The application of the composition to deformable surfaces (GFL, particle board and fiberboard, etc.) is not recommended.

- Ceresit SM-11. This glue is the most popular of the entire range. Mix is suitable for finishing brick, concrete, limy and cement surfaces. The solution is suitable for use in all types of residential, public and industrial buildings without restrictions on the effects of environmental factors. Material possesses high adhesive and frost-resistant indicators and differs in the increased moisture resistance.The brand is produced in an enhanced version of the SM-11 Plus, which is used for the installation of heavy ceramic granite slabs. The coefficient of moisture absorption of the adhesive does not exceed 3%, which is a good indicator for the composition of this price category. The adhesive layer can withstand up to 100 freezing cycles, which allows it to be used for the installation of finishing materials in the open air. Full hardening time is about 36 hours.

The solution is not recommended for use in places with high pedestrian load and frequent mechanical impact, therefore it is not suitable for finishing public areas with high traffic.

- Ceresit SM-14. The composition is versatile and has good physical and mechanical properties. It is used for decoration of premises with high levels of humidity. The material can be used for laying plates of large size, capable of withstanding more than a hundred cycles of freezing and thawing, excellent for the implementation of the exterior. The mixture has high elasticity, making it recommended for lining materials that are susceptible to deformation.The mortar is suitable for laying “warm floor”, it is well resistant to the linear expansion of ceramic tiles, and can be used to install tiles with any degree of moisture absorption.

- Ceresit SM-15. Glue is used for the installation of tiles made of artificial and natural stone, and the white modification of this brand is ideal for laying light tile and glass mosaic. The material is suitable for any type of foundation and is recommended for use on cement, brick, concrete and lime walls both indoors and out. The period of complete drying is 24 hours. The solution is highly resistant to thermal pumps and high humidity. The cost of the brand is about 400 rubles per 25 kg, which is due to the presence of plasticizers in the mixture, which increase the use time of the solution.

- Ceresit SM-16. Specialized composition suitable for finishing bathrooms, pools and toilets. Glue is used for the installation of slabs of marble, glass, stone, as well as clinker and tile products. The composition is not afraid of linear expansion of ceramic tiles and heavy weight loads.Due to its high strength, the adhesive can be used to form a tile floor in places with high pedestrian traffic.

- Ceresit CM-17. This heat-resistant composition is the most flexible and durable. It is designed for the installation of large and heavy slabs. The material is suitable for finishing plasterboard walls and ceilings, as well as for laying tiles on any deformable surfaces. Glue of this brand is available in two versions, one of which is traditional, and the second has reduced dust generation. The solution is able to withstand more than 150 freeze-thaw cycles, and is resistant to sudden temperature changes. The time of complete solidification of the mixture is two days.

Consumption

When determining the amount of material required for laying tile or installing a "warm floor", you should consider the consumption of glue. This indicator is not a stable value and depends on many factors. The fundamental point is the quality of the base on which the tile will be laid.

If the surface is a porous structure, then the mixture consumption will be large. To reduce it, the surface should be carefully prepared by dedusting, degreasing and applying a primer mixture.

The height of the teeth of the spatulas and the presence of defects in the rough base also affects the flow rate. If the surface has obvious dips or drops in height, then the flow will be significantly higher due to the need to level the base. To finish one square meter of coverage may need from two to four kilograms of the mixture.

Reviews

Ceresit glue is a high-quality and easy-to-use tool for fixing all types of tiles. Due to the ideal price-quality ratio, the solution is in high demand and has many positive reviews.

Consumers note high adhesion and moisture resistance of the material, as well as the possibility of using the mixture for outdoor use. The disadvantages include the high cost of some brands and the short "viability" of a solution of some species.

In this video, you will learn how to tile using Ceresit CM 11 tile adhesive.