Bits with a limiter for drywall: the purpose and the nuances of choice

When working with drywall can damage the sheet, which leads to the formation of cracks and rupture of the material from the back side. To eliminate such a defect during work, use a screwdriver with a bat that has a limiter.

Purpose

A bat with a limiter for drywall is nothing special nozzle on the drill. It is designed specifically for GCR, during screwing in which the limiter rests against the surface. At the same time the screw is recessed to the desired value. So tighten each fastener, not allowing the screw to fall below a predetermined level.

Excessive indentation of fasteners is the reason for the unreliable fixing of the gypsum board to the surface.

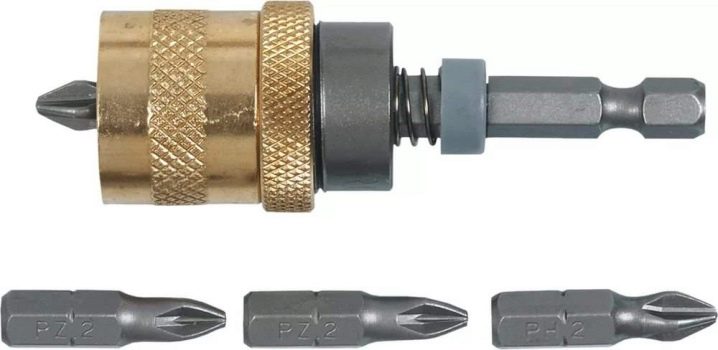

However, these nozzles have different forms of slots, which is reflected in the appointment of bits. Externally, the bit has a hexagonal shape with a length of up to 5 cm. One side of it is attached to the screwdriver, and the other side is the similarity of screwdrivers of various kinds and has an element in the form of a bowl. It resembles a cruciform variety. With its help, threaded connections are mounted or removed.

Some species, in addition to the limiter, may have a magnetic holder. This saves the master from having to hold the mount in his hand. High-quality mounting screws using bits allows you to drown them 11 mm deep into the sheet material. However, the screwing depth of such attachments is different. For this reason, the choice of bits should be approached thoroughly.

Advantages and disadvantages

Using a simple nozzle allows you to simplify the work with GCR. It is made of different materials, which causes a different service life. Despite the possibility of using such nozzles for a drill, it is desirable to stop on the screwdriver. It has smaller turns, therefore will not spoil the GCR.

A bit is a necessary thing in the work, through which:

- speed increases and the quality of work is improved;

- increases the reliability of fastening GKL to the base;

- the risk of damage to the plasterboard is reduced;

- manages to get rid of the pimple of the base because of protruding caps;

- Qualitative work with a large volume of GCR is possible.

However, not every type of bit meets the stated requirements. The disadvantage of some budget varieties is the limited duration. For this reason, one nozzle for installation may not be enough. However, according to experts, this is not always justified.

Professional masters believe that the durability of the bits with the limiter depends on the skills to work with it. If the master is working correctly, then it will serve for a long time.

Other disadvantages include the lack of adjustment of the limiter in the budget models. The analogue for professionals allows you to independently set the desired length to work with different parts of the plasterboard base.

Subtleties of choice

If you buy the first thing on the store counter, you can spoil all the work. A selection error can cause damage to the screw. In addition, rifling on the cap can lead to damage to the device.

It is worth considering the main nuances of the selection of bits with a limiter for drywall:

- Auxiliary nozzle on the screwdriver is bought only after the purchase of screws. The type of bit depends on them.

- At the time of choice is to inspect the marking bits. It should indicate that it is suitable for GCR.

- Marking on fasteners and the desired attachment is always identical. It is worth buying immediately and screws, and bat. This is usually labeled PH2.

- The most frequent type of cap corresponds to a diameter of 3.5 mm. Bat is chosen based on this.

- The length of the product may vary. You need to buy the option that is suitable for a particular reason. A short bit is suitable for the walls, and a long bit for hard-to-reach areas and corners.

- Good recommendations are varieties of chromium and vanadium, chromium and molybdenum. Allocate the master and options from molybdenum and tungsten.

- It is worth choosing a model with a magnetic holder. You need to lower the bit in a handful of screws. If 3 elements remain on it, it is worth buying.

- Must be vigilant when buying. Often cheap Chinese fakes are sold under a quality product. As a rule, they fail after screwing several screws.

- The nozzle cover must be nickel-plated. This will ensure the bits are protected against corrosion.

- In order not to suffer in the process of work, it is recommended to take a professional version of the nozzle. It has a decoupled coupling and adjustable stopper length.

- It is necessary to focus on the cost and time of work. If the tool will be used frequently, you should buy a professional version (from 2 thousand rubles). If the work is one-time, a pair of standard products is enough (from 100 rubles), since one may not be enough.

Limiter options

Few people know, but you can do a bat with a limiter for the GCR with your own hands. On the screwdriver, you can set the rotating element. Sometimes brass rings are used instead of a stop.which at the same time serves as the limiter of the screw-in depth. They just put it on the most ordinary bat and start working with GCR.

However, in this method there is a negative point. As soon as the bowl of the brass ring begins to rest on the surface of the gypsum plasterboard, it is necessary to stop the rotation on its own. The fact is that the circle can continue rotation, sliding from the end of the bit. When this happens, the slot. Sawdust is magnetized to the end of the bit, thereby complicating the fastening of the subsequent screw.

You can use a tripping clutch and a depth limiting clutch (limiting cone). By rotating the screwdriver ring, the depth is set.

In this case, during the contact of the limiting coupling with the surface of the GCR, the engine continues to work and the bit stops. At the same time, the screw also stops spinning.

Sometimes the bit stops are made of a cap for a marker and a rubber sleeve.. In this case, the cap is pruned, the rubber seal is inserted into it. Such a device will not allow the screw to screw in more than the planned level. However, for greater reliability, the design has to be improved by drilling holes on both sides of the small bolts, which is necessary so that the structure does not go a bit.

Sometimes they use nuts and even plastic as a stop.by soldering it to the bat itself. The disadvantage of this device will be no adjustment.

How to use?

Use the bat with a limiter can be when installing walls and ceilings. In this case, the best tool is the one that has an automatic feed screws. For this, a special nozzle is provided.

The use of this device is practically no different from the principle of operation. The nozzle is inserted into the tool, fix and twist the screws.

Reviews

Opinions about the bits with a limiter in the field of craftsmen and ordinary citizens are different. There is no unity here. Some users claim that the nozzles are the only way to screw the screws into the drywall base perfectly. The feedback indicated a reduction in the time required for the installation of drywall constructions, no need to monitor the pressure of the tool.. Pleases and the fact that these bits are inexpensive.

Other users are confident in their abilities and are used to doing everything with the use of a screwdriver and a restrictive cone. However, those and other masters agree that externally after screwing in the self-tapping screws by means of the nozzle, the caps are recessed into the surface identically. On the other hand, there are opinions, which indicate the inconvenience when working with such nozzles in the installation of the ceiling. According to such reviews, the bit contributes to the loosening of the gypsum, which can affect the reliability of fastening.

In the video below you will see a review on a bit with a limiter.