Gyproc Drywall: Characteristics Application

Drywall - a unique building material, which became popular and in demand shortly after its appearance. Currently, there is a fairly wide variety of this material on the market, but experts and amateurs have already chosen for many years Gyproc gypsum board - products of the company, which is part of the Saint-Gobain corporation.

Varieties and characteristics of the material

Plasterboard products of the company has a traditional structure: gypsum base and cardboard lining. Its composition is:

- 93% - gypsum;

- 6% - cardboard;

- 1% - various additives.

Outwardly, the GCR is a smooth sheet on the one hand, rough and dark on the other. In the production process, gypsum powder is mixed with water and frozen in special chambers. After that, the resulting plates are fired at 180 ° C.

Fully finished plasterboard is covered on all sides with cardboard.The whole process is carried out under certain conditions with the observance of a special temperature and under pressure, which allows you to create a dense material with an almost homogeneous structure.

Assortment of gypsum sheets Gyproc

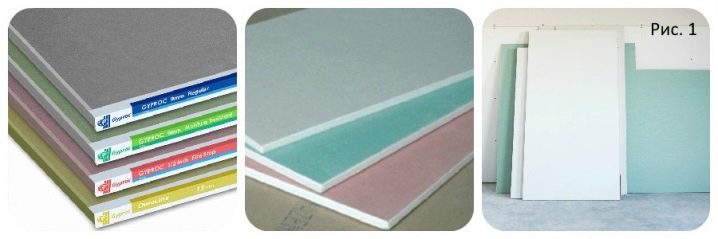

Focusing on the needs of customers, the company is constantly improving the material, expanding its range. Currently Gyproc offers:

- Regular drywall (GCR), which has a standard composition.

- Moisture resistant material (GKLV). It has the same composition as GCR, but when it is created, special hydrophobic impregnations are used, which do not allow the upper layers to soak and protect the inside of the formation of fungus and mold.

- Reinforced sheets (pls). Due to the greater thickness and increased strength, such sheets are fully capable of withstanding heavy loads (for example, nailed shelves).

- Fire-resistant drywall (GKLO). Special reinforcing threads are introduced into it, which increase its flame resistance.

- Vlago-and fire-resistant building material (GKLVO). Combines at once two improvements in the form of refractory materials and waterproofing impregnation.

- Acoustic plates (GKLA) or AKU-line.Drywall has the same composition as a regular sheet. The acoustic effect also provides a difference in the structure of the core.

Such a variety allows you to choose the material suitable for each case.

The manufacturer combined all products in several series, each of which has its own purpose:

- "Light." The products have a small weight and a smooth surface, which allows the use of products for the installation of suspended ceiling structures.

- "Strong" (super strong) - gypsum plasterboards with increased thickness and increased density. Due to the reinforcement of the sheet, it has greater strength, better sound insulation and is more resistant to external influences. Perfect for walls and partitions.

- "Optima" - a universal building material in which the strength and thickness are optimally combined. They can be used for any purpose: from arranging ceilings to installing partitions when re-planning an apartment.

- Gyproc Aqua Light. In addition to the usual materials, it contains special anti-fungal additives. Due to its good moisture resistance, it is perfectly suitable for cladding ceilings in wet areas.

- Aqua Optima. Construction material treated with hydrophobic additives, which allows you to install it in bathrooms, kitchens, bathrooms without compromising the quality of repair.

- "Aqua Strong". Has the increased durability on a bend and sound protection. The strengthened and improved sheet of such gypsum cardboard - the optimal solution for finishing works in rooms with high humidity.

Specifications and parameters

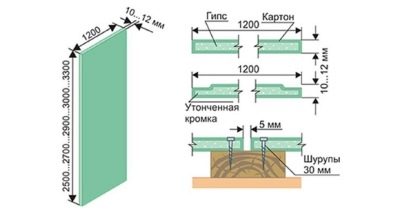

The main parameters of plasterboard - their size. The Gyproc product range includes sheets 2.5 - 3 m long and 1.2 m wide. If necessary, you can also order panels of usual width from 2 to 4 meters long or small models with dimensions of 150x60 cm.

No less important parameter is the thickness of the plate, which determines the strength and sound insulation of the product. Its standards are 6.5; 9.5; 15.5 mm. The former are used to form curvilinear structures, the latter are suitable for ceiling cladding, and the third are for installing partitions and wall cladding. In sheets of increased strength, the thickness can reach 15 mm.

The sizes of firm gypsum cardboard can vary depending on a type of sheets:

- the usual - 2400-3600x1200x13 mm;

- “Strong” super strong - 2500х1200х15mm;

- windproof - 2700-3000х1200х9 mm.

All this must be considered when calculating the amount of materials for repair or construction. In addition to the main characteristics of the material has a minor, which include color, weight, type of edge.

The color of the sheets depends on the purpose of the building material, for example, a normal HL has a gray tint, moisture resistant is green, fire resistant is red, acoustic is lilac.

The weight of the plates depends on their size. So, at a sheet thickness of 9.5 mm, its weight can be from 6.5 to 9 kg / m2, and at a thickness of 12.5 mm - from 8.5 to 12 kg / m2. A special exception is the soundproof "Aku-Line", whose weight is 36 kg / m2.

The edge type can be longitudinal straight (PC) and thinned on one side (CC). The first option is used for surface finishing and arrangement of partitions. The second - as part of a multilayer structure.

Advantages and disadvantages of Gyproc products

Professional and beginner builders and repairmen value the company's products not only for diversity, but also for A number of other benefits, including:

- High quality. Its achievement is made possible by strict control of all production processes.

- Environmental friendlinesswhich is achieved through the use of completely safe and clean materials.

- Perfectly smooth surface - This property allows you to minimize the cost of finishing the surface.

- Branded drywall does not crumble at installation, it is rather easily bent without wrinkles and cracks and is installed without undue difficulties.

As for the shortcomings, the fragility of the material is referred to as such - if it is carelessly handled during installation, or when transported, it is easy enough to damage it.

In addition, the usual GCR well absorbs moisture and is not able to withstand a lot of weight. Therefore, it is important to choose the right material with appropriate markings (waterproof, fireproof or reinforced).

Application in finishing work

Due to its diversity, drywall Gyproc is widely used for various purposes:

- It serves as an excellent “disguise” of utilities and cables.

- Drywall is in demand for thermal insulation of balconies and loggias (in combination with mineral wool or other insulation).

- Material marked GKLO is suitable for creating chimney niches.

- Moisture-resistant material is used for decoration of ceilings and panels in bathrooms, bathrooms and other rooms with high humidity.

With the help of gypsum boards, it is possible to create multi-level ceiling structures, build house walls and create partitions of any configurations. They simplify the alignment of wall surfaces for any finishing: from applying paint to laying ceramic tiles.

Installation of gypsum boards

Installing a group of sheets begins with a markup, which takes into account the location of communications and lighting. It is desirable at this stage to determine where and how shelves and other elements that are supposed to be fixed to the drywall will be located in the future.

The installation itself begins with the arrangement of the frame. To do this, guides are first installed, and then - rack profiles (in the Gyproc product range there is a metal profile specifically designed for this purpose). The step between the two profile elements is from 40 to 60 cm.

It is important to consider the greater the load on the wall, the smaller the distance between the two racks should be.

After installation and fixing of profiles, they conduct communications and produce surface warming.

The final stage - mounting GCR. Carry out fasteners with screws. Stacked sheets in a checkerboard pattern. To do this, a short (trimmed) sheet is located either above or below. In the final, all seams are puttied and glued with a reinforcing mesh, and then proceed to the external surface finish. Even with minimal skills, the whole process does not take much time and can be carried out without the involvement of specialists.

Reviews

The demand for Gyproc products is evidenced by numerous reviews, most of which are positive.

An important criterion when choosing this particular building material, many call the ease of installation and the ability to save time and money on repair and construction work. Thanks to convenient edges, the distance between adjacent sheets of drywall is minimized. Therefore, less putty is required to seal the seams.

Along with the high performance of drywall, consumers note the affordable price and the opportunity to choose the material for each case.

About which drywall is better, see the next video.