Installation and installation of plasterboard slopes

Repair of window openings does not end with the installation of glass. The final stage is the formation of slopes. The most popular options for materials considered plaster, plastic and drywall.

Using the latter has some advantages over other types of finishes.

Features of drywall

Typically, the design of the slopes of drywall is chosen by people who independently want to carry out repairs without the involvement of experienced professionals. The result is an aesthetic appearance of the window with slopes. This is due to some advantages GCR.

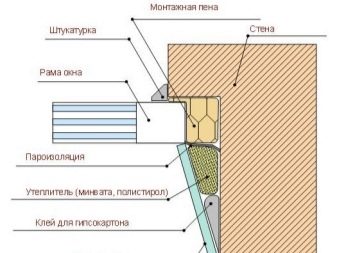

- Thermal and sound insulation properties.If you want to further warm the room, you can install double slopes with a special insulating material.

- Lightweight that allows you to make for mounting only the frame without additional amplification.

- Ideally smooth surface when using sheets GKL promotes the accelerated finishing.

- The ability to drywall "breathe", that is, when the temperature drops or changes in moisture levels do not need to be afraid of the deformation of the sheets.

- Environmental Safety. Even in combination with other additives, slopes do not emit harmful gases into the environment.

- The result is minimal waste.

However, it is necessary to take into account the material disadvantages during installation:

- it is necessary to handle drywall carefully during repairs, to avoid any damage;

- It is necessary to further protect the surface from high humidity, since even a moisture-resistant material will become vulnerable after some time when exposed to moisture.

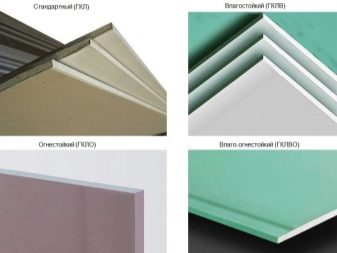

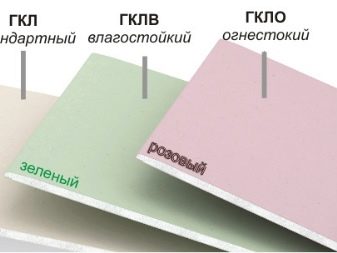

Depending on the room where you want to install slopes, choose a material with a certain type:

- with an average level of humidity in the room (up to 70%), standard drywall is suitable;

- in conditions where the humidity is more than 70%, GCRs are used with anti-fungal and hydrophobic additives;

- in conditions of increased fire hazard suitable for gypsum plaster with additives such as fiberglass and mineral wool, this option is used extremely rarely, but its equally important advantage is the high strength to mechanical stress.

Device slopes

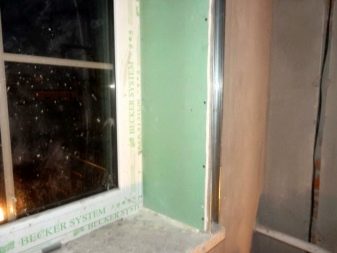

Indoors, ordinary drywall is used when making slopes. If this is a wet room - it is necessary to make slopes of moisture-resistant types of plasterboard. The thickness of one sheet is 1.2 cm. The device of slopes made of drywall allows you to seal up the joints and insulate the room, to get an aesthetic and presentable appearance of the window.

The advantages of mounting slopes include speed, low cost, low labor consumption, obtaining symmetry of the window opening and insulation, and the disadvantages are a decrease in light transmission.

Preparatory stage

Installation of slopes is possible only after preliminary preparation. For door and window openings this process is the same. However, in the first case should pay particular attention to some points.

- The presence of communications - cables, wires.It is necessary to lay them correctly.

- Possibility to install an additional door. It may be needed if the first door without insulation and there is no sound insulation.

Preparing to install slopes on window openings is as follows:

- Initially, you need to prepare a workspace. In order to be able to approach the window comfortably, nearby objects should be covered to protect them from moisture and dirt, since the installation of slopes from the gypsum board is “wet” work.

- The basis of the window reception is cleaned for good adhesion of the glue. Therefore, with the help of a brush, everything removed from the surface with time is peeled off, falls off, is poured off, and then is washed with water. The result is an absolutely clean foundation, which is carefully primed.

Tools and materials

Required tools and materials:

- drywall;

- adhesive solution;

- soil mixture;

- fasteners;

- heat insulation materials;

- spatulas;

- head drill;

- construction knife;

- water;

- polyurethane foam;

- metal profiles.

Measurements and work with the opening

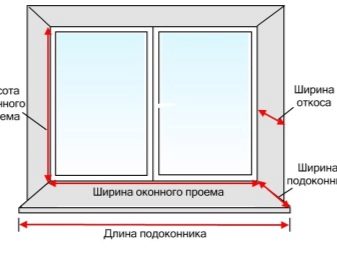

Making windows measurements correctly is very important. It is advisable to measure two times the depth of the window opening on each plane to make sure they are even. If the values diverge, you can take the width of the slope equal to the largest value.But each panel should be the same size.

If the slopes are located at a certain angle, then they should be equal on both sides.

To get the exact dimensions of the side panels, you can first make angle patterns from the GCR.

The general rules apply for installing window slopes and finishing doorways.

Operating procedure:

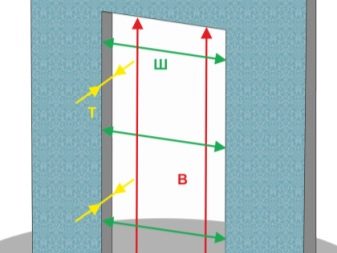

- the distance from the door jamb, window frame to the corner is measured, this procedure is done at least three times;

- stand height and horizontal length are measured, in each section the measurement is carried out separately;

- all values are transferred to the paper, and a drawing of all the elements is done.

Cutting

Drywall is easy to cut, the process includes:

- the required dimensions are transferred to the plasterboard;

- the ruler is applied to the drawn line, along it is carried out with a knife;

- I put a timber under the trim and with a few blows on the edge the sheet is broken, and the bottom of the cardboard is simply cut off;

- jagged areas are cut with an electric jigsaw or hacksaw.

Mounting methods

Installation of slopes with their own hands is done in several ways:

- using foam;

- installation on putty;

- frame mounting;

- adhesive method.

Using one of the methods, you can make the installation yourself for all types of bases.

Polyurethane foam

One of the fastest and easiest procedures for installing slopes is the use of foam. It can also be used with small gaps between the window opening and the corner of the corner. But it must be remembered that it is impossible to make a mistake with the amount of materials in this case, since this will lead to a deformation of the coating.

A specific order of laying slopes from sheets GKL is used:

- Surface preparation.

- The foam cylinder is thoroughly shaken. It is best to use compounds that are applied with a construction gun. But with a small surface area, you can do without them.

- The composition is applied with a thin layer on the reverse side of the glued parts.

- The part is applied to the surface and immediately comes off.

- After 10 minutes, the element is finally applied to the surface vertically, then horizontally, and again vertically.

- After one day, you can proceed to the finish.

This option is considered optimal if you have to install slopes in a short time.Foam in this case will serve as an adhesive composition and insulation, since it can be used to replace mineral wool.

Installation on putty

The option with a putty is chosen when they want to make the slopes safer and stronger.

Operating procedure:

- thorough surface preparation, preparation of the mixture;

- application of the solution on the wrong side of the part over the entire area of the panel;

- placing the element on the surface, while it must be done so that it adheres well. For better adhesion, the base is sprayed with water to moisten. And for the reliability and durability of fixation set spacers.

- each fragment is placed on the surface, after which it is left for two days for better setting of the mortar and base;

- performance of finishing.

The result is a reliable coating.

This method is suitable for mounting slopes on the entrance and interior interior doors of plasterboard.

Frame Mounting

This method allows you to get a practical surface, but it is important to know that the material is fastened with screws or dowels. Therefore, it is necessary to adhere to certain rules, for example, screws must be twisted without a depression on the surface,and flush.

Creating crates:

- it is necessary to equip with wooden beams or metal profiles;

- cut out of the guides, the dimensions of which were obtained during measurements;

- if necessary, the frame can be insulated with mineral wool;

- drywall elements are installed only after the crate was created;

- screws fix all parts to the surface.

This method is suitable when the installation of slopes is performed in conjunction with the facing of adjacent walls. When working with doorways, its size will be somewhat reduced.

Adhesive method

This method of installation, at first glance, seems simple, but there are some difficulties, for example, it is necessary to observe the tilt angles when sticking elements. The adhesive method is recommended when there is a need to keep the original size of window openings.

The advantages of the adhesive method include:

- speed of execution;

- minimum amount of materials;

- before painting the surface, it is enough just to putty on the slopes.

Plasterboard slopes are coated with glue. To prevent the adhesive composition from spreading after pressing the element to the surface, glue should be applied in a non-continuous layer onto the drywall.

So that the upper parts do not fall off while the glue dries, use spacers that abut the window sill or on the floor, and fix the plasterboard parts with the other end.

After installing the slopes may be necessary to seal the joints. In this case, acrylic sealant will come to the rescue, which helps protect cracking joints. He can give the desired shade of acrylic paint.

Design of the corners

The gap between the wall and the drywall plaster. The resulting seam is trimmed with reinforcing tape or mesh, and then puttied.

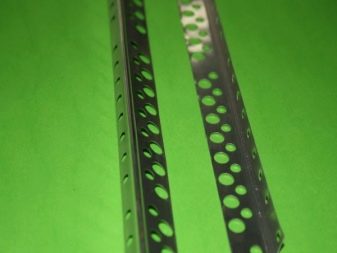

The corners are reinforced with a perforated corner, which is attached with a stapler.

Finish

Finishing is necessary to make the design presentable. For this process, you need to get putty and paint. And you can also install profiled corners of metal to prevent premature wear of the corners of the sheets of drywall. To do this, perforated protective parts are mounted on the corner slopes. In order to avoid voids and irregularities, the adhesive composition is applied with a thin even layer, as when working with elements of slopes.

Further work is carried out to strengthen the corner of the room.

- The protective part is pressed into the fixing solution until it stops. Glue or putty can be used as this solution. Excess solution is removed with a spatula.

- It is necessary to constantly monitor the flatness of the lines vertically and horizontally, which will require a building level. After mounting the profiled elements they putty. On the slopes of the protective composition is applied in several layers, while regularly leveling irregularities and bumps.

- Minor irregularities can be eliminated with sandpaper or sanding machines.

- After the putty dries, the defects are masked with a primer of the surface in several layers, regular cleaning with an abrasive mesh.

Rubber paint is recommended for finishing., providing the ability to wash slopes and protect the surface of entrance doors and windows from damage.

Before painting, it is necessary to treat the base with a fly-brush, a roller for the appearance of roughness. In this case, the paint will fall evenly. Paint should be in two or three layers to evenly covered all areas.

Observance of all nuances will allow to avoid the appearance of defects not only upon completion of the finishing process, but also under further operating conditions. However, most often in the early stages of work, mistakes are made when measuring and cutting sheets of drywall, which leads to damage to the aesthetic appearance of the whole structure.

The most common problem is the appearance of gaps between two panels. In order to avoid this problem, use liquid material, but no fundamental changes will occur, since drywall and plastic differ greatly in texture. In this case, experts recommend the use of plastic profiles for the design of the side and bottom sections of the construction of gypsum boards.

This will help to hide a loose fit or noticeable depressions and tubercles.

But it is also undesirable when installing inclined slopes to fill the gaps with glue. If the gap near the window frame is more than 30 mm, it is advised to glue it with a strip of plasterboard, where to glue the slope.

See how to make window drywall slopes with your own hands in the next video.