Types of drywall mills and manufacturers review

Drywall - a building material that is very popular. With it, you can do any work: align the wall or make the interior partition. Often with the help of plasterboard sheets, various arches or structures with increased complexity are formed.

During the construction of such structures, it is often necessary to minimize the number of joints between GCRs. To avoid a careful adjustment of each such joint, its soil, reinforcement and puttying, experts increasingly resort to the preliminary preparation of drywall - to its milling.

This process allows not only to carefully cut the sheets of material, but also to create a variety of holes in the gypsum board, as well as cut out the grooves of complex geometry.

Material Features

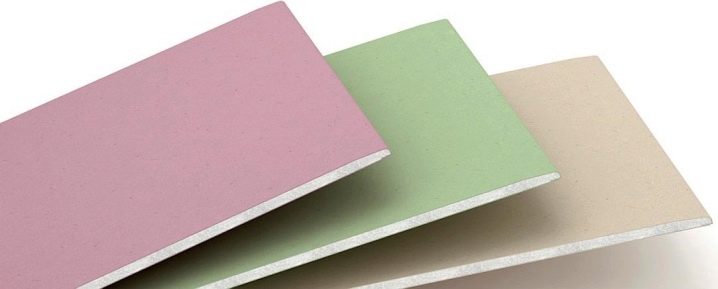

Drywall is a rectangular sheet of small thickness. It consists of a plaster layer, which is covered on both sides with construction paper - cardboard. Due to the fact that the material is simple and easy to use, it is quite possible to do the installation by yourself - just need to stock up on the necessary tools in advance.

Drywall in its composition does not contain harmful substances and chemicals, so it is absolutely safe for health. The product can serve for a long time, but only in those rooms where the humidity is not increased, otherwise it will simply deteriorate.

Sheet plasterboards vary in color and size. Its thickness is different: 8, 12.5, 16.5, etc.and the color is gray or blue. But there are such types as GKLV (moisture resistant gypsum plasterboard), GKLO (material with high fire resistance), GKLOV (fire and moisture resistant gypsum cardboard).

Advantages and disadvantages

Milling drywall, like any other construction process, has its advantages:

- Time saving. The use of the considered technological process reduces the cost of working time during the construction of boxes and corners.All, without exception, performed significantly quickly. In addition, there is no possibility to spoil the material, if you follow all the tips.

- Reducing the number of open ends. This makes the design tidier and also greatly simplifies the work: there is no need for puttying and grinding. In addition, you do not need to fix everything except bends - this significantly reduces costs and makes it possible to save time.

- The possibility of forming systems without the construction of the frame. If the box or coal ledge will not be a load, then you will not be able to increase the profile of similar components. They themselves possess good hardness and stand for many years without deformation.

The downside of this method, perhaps, is only that for the work will have to buy a machine for milling. However, if you do repair work in your own home infrequently, it is easier to use a tool rented at a store or from a friend.

The cost of maintenance is low, so you will save substantial funds.

Requirements

For the formation of the groove will need a special device - electrofrezer. It is not recommended to buy expensive professional equipment. in case the specialist is not interested in processing drywall regularly and it is necessary for him for individual needs. In this case, we can limit ourselves to an economical view - the conditions for the router are not so demanding.

Milling should only be done in a smooth and firm plane., excluding minor sagging leaflet. Experts advise to use workbenches (often deliberately, without the help of other blanks for these purposes).

However, you can do without them, carrying out the procedure in a smooth plane of the floor or on a stack of sheets.

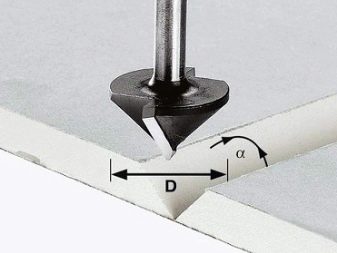

V-shaped cutter used for the selection of the necessary grooveIt is considered a curved device. For this reason, in order to obtain straight bend directions, there is no way to limit ourselves to the use of specialized push tires or different patterns.

They are usually made from scrap materials, the most common of which is plywood. In order to perform a straight cut, the template is fixed on the drywall, after which the electropulser is guided along its border.

Manufacturers

From among the popular manufacturers of electrical equipment for the processing of drywall use milling cutters of the following brands:

- Bosch - this type of product is in great demand because it has great technical abilities;

- "Enkor" - the equipment of this brand is made of strong, high-quality material, contains soldering from a hard alloy, is distinguished by durability and a long service life;

- "Globe" - the brand is known for the release of a durable device designed for processing hard or soft wood.

- Sekira - for the manufacture of devices of this brand are used hard alloys, high-speed steel - this makes it strong, comfortable in work.

The choice of brand depends on the drywall surface, machine size or cost. In addition, it must fit the technical process.

Main types

Disk milling cutter with Strong cutter is needed for the formation of straight grooves and sawing drywall itself. Its advantages are speed and purity. But to create grooves of a more complex shape, this tool will not work.

Shaped milling cutter performs milling GCR.Often it is used for cutting out more complex grooves and creating various forms of holes: round, oval and others. This tool uses the Festool cutter.

Milling sheets of drywall makes it possible to realize the most unusual design ideas that could not be realized with a knife. Only milling makes it possible to acquire a perfectly smooth edging, which is especially significant in variants where several elements meet in one plane.

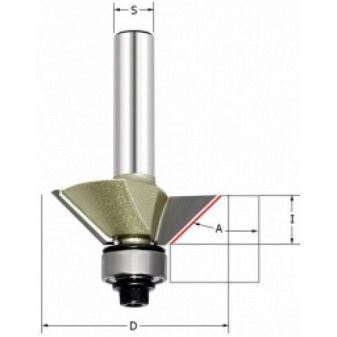

For any case using specialized cutters. Often the following varieties are used:

- straight - makes grooves and holes that are at an angle of 90 degrees;

- edge cap - used only if you want to remove the chamfer;

- T-shaped - allows you to create extremely large holes;

- U-shaped - forms the grooves of the semicircular shape;

- V-shaped - used for cutting triangular grooves.

As a rule, such a set of cutters should be at any highly professional specialist,which often need to use similar nozzles for processing plasterboard sheets. The home wizard for the treatment of gypsum will have a main V-shaped cutter.

Using a V-shaped cutter, Festool can be used to manufacture various plasterboard products.while the sides will dock at a right angle.

This feature allows you to create straight angular surfaces with a minimum number of joints. When selecting, you should pay attention to the size: it must fit the router. Often it is a diameter of 32 mm. But in order to mill GCR, you need to know how to use them, and also buy a good frezer.

In order to use a V-shaped cutter, you need to purchase a milling machine. Such equipment is quite expensive, so not everyone will be affordable. To self-mill drywall, no need for expensive fixtures, you can do the job with a handheld device. Prices for hand tools are low, the device performs any cutting of drywall, and most importantly, quickly.

Using a hand tool, you can easily change the angle of the cutter.

Before starting work, you need to adjust the cutter so that the nozzle itself does not damage the bottom layer.After that you can start working directly with the tool. If you do not mark the exact point of the cut, then make a mistake. In this case, you will have to take another sheet of drywall and start the process again. In order to start work, you should apply a measure for the slice and hold the router along the marked lines.

If you want to get the perfect cut, if possible, perform milling and on the back of the sheet. To do this, turn the sheet neatly and move the tool along the marked lines.

Milling technology allows you to make any form of construction, but you need to follow the above rules - only then you will get the desired result.

Recommendations

If you mill without connecting a vacuum cleaner, this will lead to pollution of the room.

Milling on wood is better not to perform, as the tree is denser than drywall, so the edge will turn out rough and ugly.

For good work, you need to use only quality cutters - take care of this in advance!

If finances allow, it is better to purchase a full set of cutters for work.The set allows you to make the necessary incision and cut a certain part of a different shape. The presence of a large number of nozzles will also allow you to process the material at any degree of inclination.

But novice craftsmen are advised to buy cheaper cutters, because you need to learn how to work with a router. Later you can buy new, more expensive kits.

Buy cutters should be in special hardware stores. There you can find their different types and different price category. It remains only to do everything with your own hands.

You can find out how the drywall is milled by looking at the video below.