Plasterboard screws: types and step by step instructions for use

Drywall is a fragile material that requires careful handling. To ensure the integrity of the design help a variety of fasteners. Of the latter, the highest demand possess screws. Accurate and quick entry does not disrupt the drywall structure during installation work.

Special features

Screws are fasteners consisting of a metal cap and a rod with a sharp thread. The upper part has a special recess into which the tool is inserted for the implementation of the rotational motion.

Self-tapping screws are in many respects similar to screws, being considered as more advanced version. They do not require additional drilling holes. Details can be immediately screwed with a screwdriver or screwdriver in drywall.

Outwardly, both fasteners are almost the same. The screw under the cap has a smooth rod, while the screw has a sharp thread on the entire surface of the rod. Small products in the construction market are sold by weight, but large samples can be purchased by the consumer individually.

To correctly select the mounting for drywall, you need to know the basic technical characteristics according to GOST, namely:

- the length of the screws varies from 11 to 200 mm. Fasteners for decorative profiles may exceed these parameters;

- for wood, products with rare carvings are used (according to GOST 11371-78), since the wooden material is rather fragile;

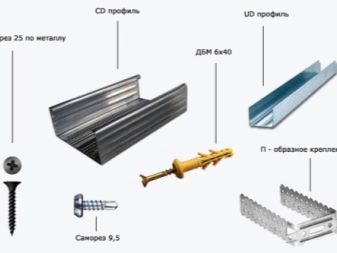

- in the case of a metal profile in accordance with GOST 11652, self-tapping screws with fine threads are required. In this case, the upper part has an increased diameter.

Production according to GOST takes into account all requirements and security measures.

Self-tapping screws are demanded practically in all types of construction works. Different types of parts have individual assignments, parameters and models.

Depending on this, before purchasing the screws, the consumption of screws is 1m². It is necessary to adhere to the rule - the length of the product must exceed the thickness of the drywall per centimeter. In the case of a wooden frame, the installation pitch is 35 cm. For a metal one, it takes 30–50 cm. Large products (from 200 mm) are used for multi-layer gypsum board or when a plinth is attached to the gypsum board. To ensure sufficient rigidity, parts are screwed in more often. The step of fixing a sheet of drywall to the surface is from 30 to 45 cm.

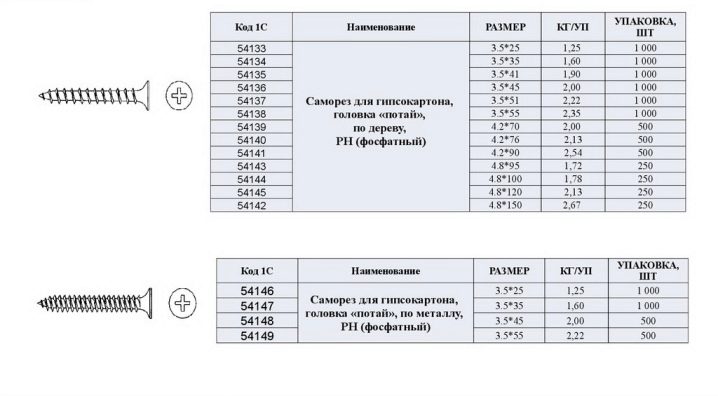

Find out the number of screws that are needed for the work, help table.

Calculation of materials | ||||||

Surface view | Gap, m | Foundation, s / m | Plasterboard sheets 12.5 | Screws, pcs | ||

Long-life carriers | Around the perimeter | For installation of plasterboard, mm, m² | For mounting an additional item L = 30 mm | |||

GP 1 | 2 | 1,5 2,2 2,5 | 1,0 | 1,3 1,0 0,8 | 18,0 | 4,3 |

As an example, it is possible to calculate fasteners for a wall with parameters of 4x5 m. It is important to remember that a standard drywall sheet has a size of 1.2x2.6 m. Because of this, in addition to guides, between which a screw is screwed along one screw, install jumpers horizontal type (40 cm above the floor and 40 cm below the ceiling).

The base is made according to the following parameters:

- the distance between the guides is 60 cm;

- HL sheet horizontally screwed to 3 guides;

- estimated pitch is 30 cm.

Calculation is made:

- 260: 40 + 1 = 8 screws on the profile;

- 8 * 3 = 24 elements on three guides jumpers;

- 24 + 6 = 30 fasteners on the sheet GKL.

Consumption per 1 m² GCR will be:

- the final result is divided into an area of a sheet of 30: 3.12 = 10;

- the wall area is calculated (4x5 = 20 m²) and the total number is calculated (20 * 10 = 200).

Materials are encouraged to purchase in reserve for 10% more of the total. Therefore, it will take about 220 pieces.

How to fix?

The caps of the screws are of different sizes, differing in the geometry of the grooves. Depending on this, a cross-shaped or flat attachment is chosen for the tool for tightening.

As the latter, you can use a screwdriver or a classic screwdriver.

Screwdriver is a pistol, which sits on a bit - replaceable nozzle of various shapes.

It is important to remember that during operation, the drill wears out, thus requiring regular replacement. And you should also think about the need for a tool with a battery.

Low cost cordless screwdriver is not adapted for long work. Charging lasts for 30-60 cycles, after which the device may fail.

The purchase of a power-assisted screwdriver can eliminate this drawback. It is a classic drill with a set of additional features. The gearbox enters the gun; its lowest speed reaches half a turn per second. Rotation depends entirely on the force pressing the trigger. When buying, it is recommended to take a reverse rotation screwdriver to turn the screw out of the socket.

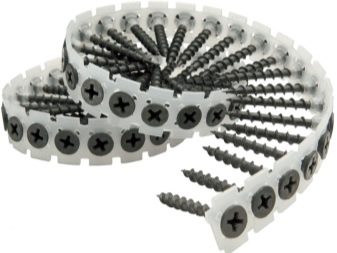

To facilitate the manipulation of the screwdriver is recommended to purchase screws in the tape. The fasteners are coupled together in an amount of 6–7 pieces, they are fed into the pistol of the screwdriver automatically. If you need to screw a small number of screws, you should use a screwdriver with a suitable nozzle. The tool handle must be sufficiently thick for ease of operation.

How to choose and fix?

When self-arranging home interior should be determined in advance what kind of screws fasten drywall directly to the wall.

It is recommended to calculate in advance the number of fasteners, while it is worthwhile to pre-measure the area of the plasterboard. In order to avoid additional overpayments, the majority of sellers in the construction market pack up separate lots of self-tapping screws into industrial packaging for hundreds and thousands of pieces. And also most often the construction market offers to buy a batch of screws by weight. At the same time there are difficulties with the calculation of 1 m². To eliminate misunderstandings, you can ask the seller about the approximate number of fasteners in a unit of weight.

To calculate the exact number of screws, the following parameters are required:

- the distance of two fasteners relative to each other;

- type of drywall sheet;

- profile material;

- the area of the room or the part where the work is done.

The installation process of screws consists of several stages.

- Before starting work, you should plan the installation location of the screws. For quality work, experienced builders recommend to drill at the marks with a thin drill of the recess to 2 mm. This eliminates the risk of loosening the screw through tight twisting in the material.

- For convenience, it is better to use a screwdriver having a reverse direction of rotation, especially when the ceiling facing. When attaching the gypsum board to the wall, you should try to keep the tool and screw as horizontal as possible. Any distortion ensures unstable design.

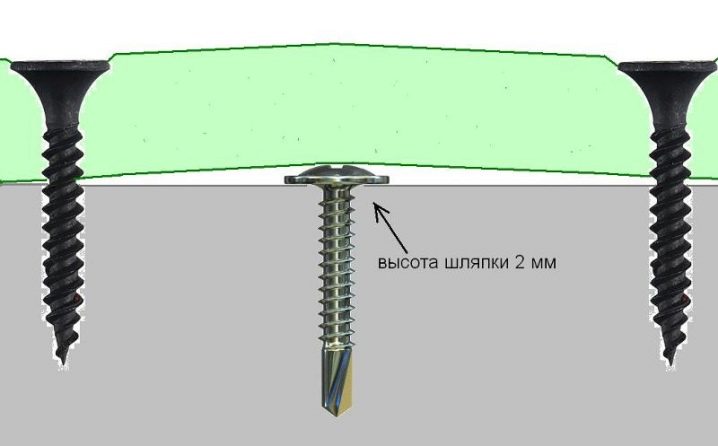

- The cap of the screw should be located at the level with the drywall surface or at a depth of up to 1 mm. To facilitate the situation will help marking the drill on the screwdriver.

- In case of unsuccessful fastening it is impossible to make a new hole within 5 cm from the wrong one.

- The screws begin to twist with the rapid rotation of the screwdriver. When the fastener enters the gypsum, the speed of the drill is dropped to its minimum.

However, when installing the consumption of screws can unexpectedly increase due to the purchase of defective products. To avoid unpleasant consequences, you should pay attention when buying a few details.

- Colour. Self-tapping screws possess an equal black or grayish-black shade, similar for each product in a batch. Such a color gradient indicates a high-quality corrosion-resistant coating with oxidation or phosphating technology.In the absence of a protective layer in conditions of high humidity, self-tapping screws will quickly rust.

- Recess under the slot should be located in the center of the cap, observing a clear upward direction. Poor slot will not allow to screw the screw into the drywall.

- Appearance. Products in the lot must retain the same shape and size parameters. Even bent elements indicate a defective batch, they are made with violations at the production stage. Poor-quality products are not marked on the cap. The presence of letters means that the manufacturer has entered the market openly and fully responsible for the quality of the product.

Kinds

To work with GKL suitable conventional screws, which are fully included in the sheet. Differences begin with a geometric indentation in the cap. Determined cruciform, straight and hexagonal neckline.

Self-tapping screws with a complex slot are more in demand on the market, since the cap is not susceptible to damage. If necessary, they are easier to unscrew.

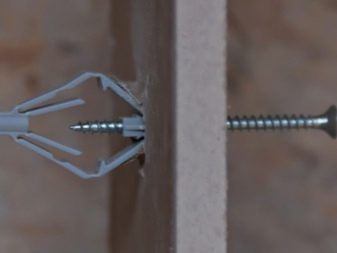

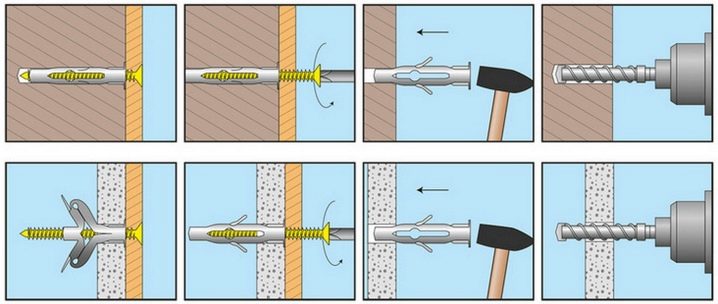

If the plasterboard is required to hang a massive structure, it is better to use the butterfly mount. This type of attachment is able to withstand loads of up to 30 kg. The fastener consists of a self-tapping screw dowel with a plastic core. When the element is screwed in, the dowel easily enters the plaster, forcing the plastic seal to fold, pressing against the drywall from the rear. Installing the "butterfly" begins with drilling a hole with a diameter corresponding to the circumference of the screw rod. The hole length must be 5 mm longer than the plug. Before inserting the screw it is necessary to remove dust.

Material

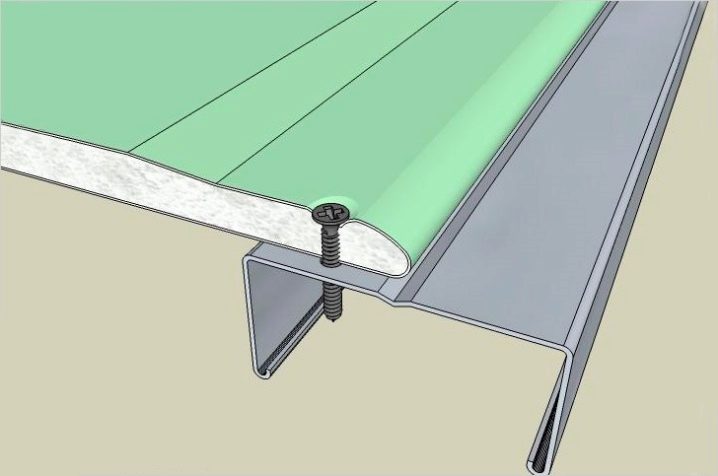

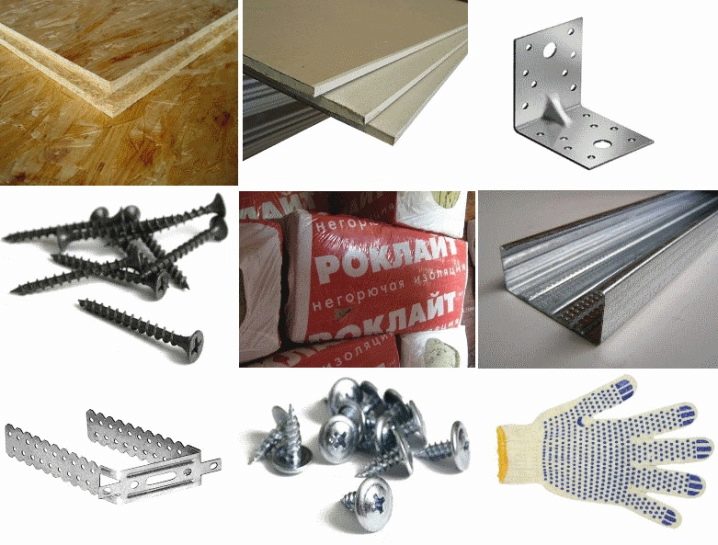

For a profile for a drywall made of wood, large self-tapping screws with reverse partial thread are required. The coils are divorced in the middle due to the ductile structure of the material. The tree has a low density, due to which it requires special screws for drywall. The diameter is not inferior to similar products for metal, while the length is from 11 to 200 mm. Large models with a thickness of 4.5–5.0 mm and a length of 150–200 mm are twisted into a pre-drilled hole.

Metal screws have a frequent thread on the rod. The distance between the ridges is small, since a tight adhesion of the rod to the metal profile is necessary. The diameter is 3-5 mm.As the length of the screws increases, the diameter value also increases.

Brass, alloyed or stainless steel is used as a material for manufacturing. Steel products have high density characteristics, while brass products better resist corrosion.

Thread Type

In the case of operation of metal profiles using drywall for metal, while for wooden crates required GCR for wood. Based on the cladding material, select the appropriate screw, focusing on the appearance of the thread.

Regardless of the specific purpose (wood or metal), screws have the following characteristics:

- PH-2 (Phillips) is a cross-shaped groove, with which it is convenient to twist the screws into the sheet with a screwdriver and a screwdriver;

- the twisting of the screw into the drywall facilitates the sharp spiral-shaped thread on the rod;

- the presence of a cap, which is embedded in a sheet of gypsum plasterboard and does not complicate further cosmetic finishing;

- black color (without additional coloring and grinding) indicates corrosion resistant oxidized and phosphated coating.

For wood, a rare thread pitch is characteristic, and for a metal profile it is frequent. The latter is a reinforced version with a thickness of up to 2 mm, which requires the participation of self-tapping screws with a drill.

This type of attachment does without additional drilling holes. Thus, they reduce the time to install drywall to the wall, despite the small distance between fasteners.

Dimensions

Manufacturers make batches of self-tapping screws for GCR sheets of various sizes. The wide range is caused by different-sized purpose of fasteners. It is not always necessary to fix the drywall to a wooden crate or wall. In some situations, to increase the density, two sheets of drywall are attached, which require a longer self-tapping screw. As well as the parameters of fasteners depend on the density and distance to the material.

It is better not to rely on intuition and to choose the length of the screw according to the marking. For example, on the package indicated 4.8x100. From this it follows that the screw has a diameter of 4.8 mm and a length of 100 mm. Experts recommend that when choosing a self-tapping screw of a certain size, proceed from the basic rule: the cap of the fastener should go into the drywall to a depth of 1 mm.

Famous manufacturers and reviews

Leading position in the ranking of manufacturers is an international company. Knauf. The company manufactures self-tapping screws for drywall for various purposes. Fasteners from the German manufacturer have several advantages.

- A sharp rod and a hidden cap are covered with phosphated anti-corrosion protection. It allows the use of screws in dry conditions, and in rooms with high humidity.

- The standard construction step is from 11 to 200 mm. For multi-layer plasterboard coatings, Knauf produces an additional line of self-tapping screws up to 750 mm long.

- High-quality metal for the manufacture does not allow the collapse of the geometric grooves in the cap of the screw, providing a tight match with the screwdriver bat. They withstand heavy loads at a speed of 2 revolutions per second.

- Each screw has a logo on the cap "K". In the construction market, manufacturers put the label only if there is a stable product without flaws.

Magnetic bits with interchangeable nozzles are produced for self-tapping screws, which guarantees more than 1000 unwinding. Significant competition is the company Omax, which marks the products with an "X".The company maintains high quality standards, not yielding to an international manufacturer from Germany.

After using Knauf products, consumers leave only positive feedback. However, the German quality severely hits the wallet. As a budget option, you can buy domestic or Chinese products. Manufacturers from China have raised quality standards. The screws are also covered with anti-corrosion compound, but the unwinding warranty period is reduced by one and a half times.

Tips and tricks

Experts recommend sticking to the following tips when working with screws:

- when fixing drywall to the wall, it is necessary to embed the screw to a depth of at least 1 mm;

- it is recommended to disguise the fastener caps in the subsequent painting to create an aesthetically attractive surface;

- to create a smooth coating, you must putty recessed caps;

- in the presence of holes from unsuccessful twisting, it is necessary to cover up the holes of the screw;

- when visiting the construction market, it is important to purchase an additional set of drywall or self-tapping screws,as during self-repair may not be enough of the necessary elements. At the time of need similar products may not be in the seller;

- do not neglect the security measures. Protective gloves should be purchased for the protection of hands. During production, sharp metal particles that are invisible to the naked eye are deposited on the screws. They are able to pierce the skin in the palm, contributing to infection. Therefore, do not ignore protective clothing.

Successful examples and options

The classic use of screws for the installation of drywall - this hay trim additional elements of the interior. The result is a plastered, sanded surface that is easily painted.

In addition to walls, plasterboards are cladded with ceilings, giving construction reliability with self-tapping screws.

Review of screws for mounting drywall, see the following video.