How to choose a floorboard?

The floorboard is an excellent substitute for expensive parquet. But before you go to the hardware store to buy this flooring, it is very important to know some of the nuances of the floorboard, which will be faced in the process of its installation and operation.

Kinds

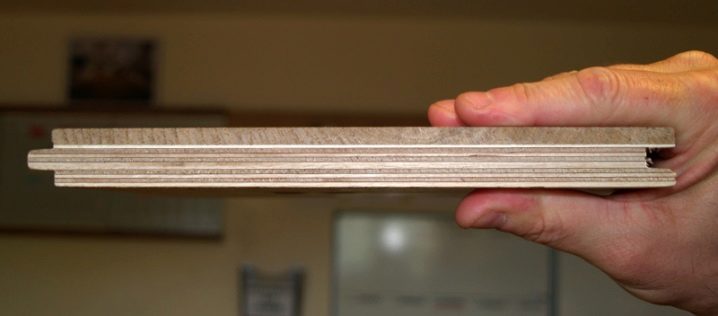

The floorboard was created as a relatively cheap replacement for parquet and solid board. In the first years of its existence, bilayer specimens were produced, and the modern version appeared a few years later, and for more than half a century it has been produced unchanged. The first layer - the lower one - is a kind of substrate, which protects the base, which, in turn, is made from inexpensive tree species, most often coniferous - pine, larch. The front layer is not just a decorative coating, but also protective.On it, as a rule, there is a cut of expensive woods.

By the way, the main layer consists of transversely laid plates, and at the upper and lower layers of the board are parallel.

Thanks to this technical solution the product in finished form has high strength. So, the floor will not bend under the weight of large furniture. It will withstand temperature changes.

Depending on the pattern, the face layer is made from domestic wood or imported wood. The latter can be attributed to exotic breeds, the cost of which, of course, from this will be higher. Oak, walnut and birch are often used on the European continent, less often ash, beech and cherry. When ordering individually, special raw materials are imported - wenge, merbau and dussia. All these varieties are distinguished by their physical characteristics - color, hardness, as well as a longitudinal slice.

It is not necessary to use the natural color of wood, at the production stage it can be stripped, painted, whitened.

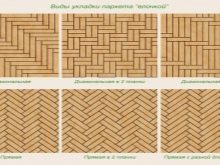

The floorboard can be single-sided, two-way and three-way. A three-strip board, or rather its top layer, resembles visually a parquet laid longitudinally.This kind of board is recommended for residential and non-residential premises. Probably the most three-lane parquet boards will appeal to lovers of classic parquet. After all, they do not have to spend time laying parquet, cut dies.

In the two-lane floorboard, respectively, two rows. At cost, it is a bit more expensive, but it can have several types of graphic design. Plank board is a kind of enlarged laminate, it uses solid lamellas, therefore the cost is higher. Less commonly on sale you can find multi-band options.

Before you get to the counter, floorboard varnished. Due to this, building material does not deteriorate under the action of ultraviolet radiation, mushrooms and pests do not inhabit it. The waterproof parquet board perfectly transfers casual spilling of water on a floor.

Moisture resistant parquet lamella is made of solid wood. This is due to the fact that they contain the largest number of oils and resins that can stand up to temperature and humidity drops. Make it from tick, wenge or Balau. Such a building material feels great in the bathrooms, in the kitchens and in the corridors.

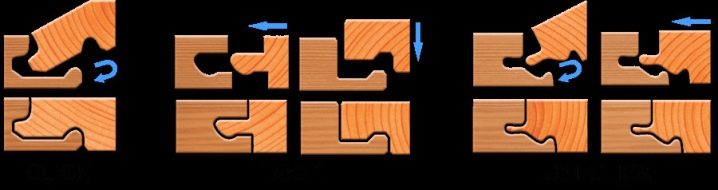

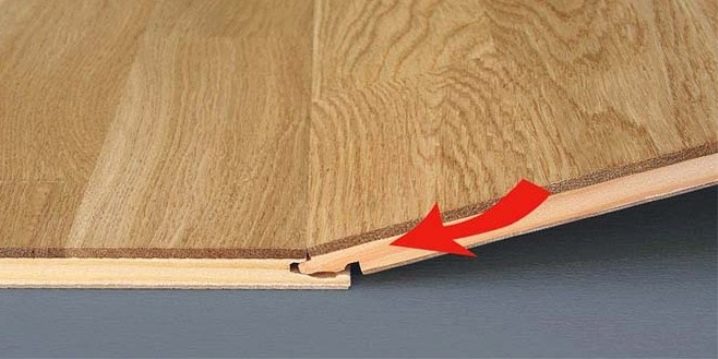

The floorboard has several options for locking connections. The most common are Lock and Click. Advanced lock Uniclic allows you to lay the floor in such a way that the seams between the rows and products are not formed.

Seamless floorboard looks great in urban apartments, and in country houses, and in commercial premises. Moreover, it is possible to stack not only diagonally, but also as a herringbone. Technology laying "French tree" is known since Soviet times.

And some manufacturers, on the contrary, for the best imitation of a wooden floor make their products with a chamfer. From a distance it is very difficult to distinguish it from a natural parquet, and given the fact that its installation is easier and the cost of a parquet lamella is lower, then all the advantages are obvious.

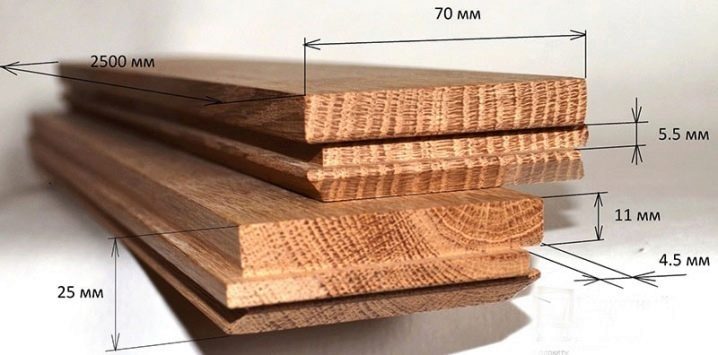

Dimensions

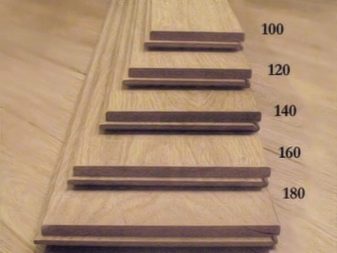

The width of the parquet lamella starts from 13 cm. This is its smallest indicator, it can reach up to 20 cm. Starting from the width of the product, you can understand which board is easier to install, transport, and which is easier to care for.

The thickness at the same time can start from 0.7 cm.Such a parquet board will not be a good soundproofing product, its durability will be lower. The thickness of the building material can reach up to 2.5 cm. It will be harder to damage it mechanically. no extraneous noise will enter the room, the floor will always be warm.

Thin parquet board is suitable for those rooms where interior doors have already been replaced, and trimming them is undesirable. Products with a thickness of about 2 cm are perfectly combined with a heating system. But it is better that the "warm floor" was infrared, because the electric can cause a fire, and water - to flooding.

In the premises of a commercial or social orientation it is necessary to lay the most durable parquet plate, this will increase its service life.

The last indicator is the length. The smallest is a board with a length of 180 cm, and a maximum - 250 cm. But remember that the long board is harder to mount. At the same time the long parquet board is exposed to smaller vibrations, is not deformed under the human weight, does not creak. Yes, and visually this product looks better, because it has fewer connecting seams.

Special features

The main advantage of the floorboard is its cost. Unlike its predecessors - parquet and solid wood, it is cheaper. Its installation is made using a locking connection, which can handle any adult. Floorboard does not require such care, which is needed untreated tree.

This building material is able to absorb extraneous noise, does not form static electricity, has insulating properties. Yes, and the appearance of the product is beyond praise, the colors can be matched to any interior.

Well, the disadvantages, of course, she has. First of all, it must be said that most often the parquet board is laid out of non-resistant wood. therefore when interacting with moisture, the board can quickly become unusable. If the protective layer is damaged, the product will need to be restored.

What is different from a massive board?

The massive board is an integral material. It is made of a piece of wood, so at the production stage no bonding agents, including glue, are used. From this we can conclude that a massive board is an environmentally safe material,it can last for more than fifty years, provided it is properly maintained, is easy to repair, thanks to its thickness, scraping can be done up to seven times. Like any tree, massive board retains heat in the winter season.

At the same time, it is possible to call both a plus and a minus. non-repeating pattern of massive board. On the one hand, this unusual solution will appeal to creative people, and on the other, the rest will have to repaint the floor.

If a tree is not varnished or painted, then it starts to deteriorate under the influence of humidity and with a temperature difference. Installation of such a floor is difficult both in terms of work and from a financial point of view.

Depending on the manufacturers, the thickness of the floorboard is usually 1.6 cm. But it is sold at a reasonable price, it is easy to install. Some varieties of the parquet lamella are also mounted in rooms with high humidity.

Compared with a massive board, flooring will last less time, because its thickness is much thinner. In this regard, walk on its surface with a grinding machine will get only three times. But in case of failure of one board it can always be replaced.

Remember that it is very important to study the composition of the floorboard. In cheap products can be harmful to human health adhesives, emitting formaldehyde. If there are allergies or small children in the family, this should be approached with the utmost responsibility.

Wood species

The main characteristic of wood in the manufacture of floorboard is its hardness. Even in past centuries, a special method for measuring hardness was developed, which is still used today. In order not to go deep into this process, we will use already known data:

- Among the trees growing in European countries and in most of the Russian Federation by hardness stands out oak. Oak boards are distinguished by their durability. It is not surprising that the top layer of the floorboard is usually made from this breed. The board is distinguished by its stability to changes in humidity and temperature; during operation, the floor does not dry out, does not crack.

- Love for the beautiful pattern beech manufacturers and buyers of floorboard. But it is less resistant to temperature changes, it can deteriorate at high humidity.Heat treatment of wood at the production stage is capable of correcting the situation; after that, the building material can also be laid in technical premises.

- Maple and ash in terms of hardness at the same level. These light wood species look great in rooms where Provence, Art Deco and hi-tech prevail.

- Nut American has a hardness factor of about 3 - this is an average indicator with stable qualities. Over time, you will notice that under the action of ultraviolet light, it begins to lighten.

- Cherry Furniture and cherry floor rarely found in stores, but it is worth noting that this wood has good hardness and stability.

The specific color may darken over the years, so experts recommend keeping the floorboard out of direct sunlight.

- Natural Pine used to make the base layer. Although it is softer in its structure in comparison with the breeds described earlier, but it costs an order of magnitude less, thanks to this, manufacturers can adjust the cost of the final product.

- Merbau In comparison with the rocks described above, it is distinguished by high hardness indicators, in some cases one and a half times higher than its competitors.Wood, which is imported from Indonesia, has a chocolate-golden color. Due to the high content of oils, it does not deteriorate under the action of moisture. But its hardness is also a disadvantage - it is very difficult to process such wood at the production stage.

- Wenge. The color of wenge is well known to the domestic consumer. It resembles black. This dark wood species is from Africa. Her hardness index is higher than that of merbau, the saturation with essential oils, respectively, too. These indicators directly affect the durability and moisture resistance of the floorboard. It is not difficult to guess that the final cost of products made from this type of wood is very high.

- Kempas. African "relative" of wenge. It has a golden orange color and high hardness. Mechanical effects for it are not terrible, but, unfortunately, in rooms with high humidity it is not recommended to stack it.

It is impossible to describe all types of wood within this section, and it is not necessary. After all, each manufacturer has the right to use the material that he sees fit.

Color solutions

Gone are the days when you had to buy the building material that was offered in the hardware store. Competition has done its job. Today, any manufacturer, wanting to please the buyer, produces an unlimited number of collections.

If the room is bright, then white parquet or any whiteboard will suit it. With this choice, daylight will be reflected from the floor and visually expand the space. White color is perfect for loft style, Provence and retro. By the way, for the loft style the classic design of the floor is suitable - an aged board or mahogany.

Expensive tree species look great in offices, government offices and country cottages.

Blackboard and building material in experts recommend using wenge color consciously. Dark shades can darken the room, for dark rooms need additional lighting, furniture with chrome or gold inserts. It is desirable and a large number of mirrors. If you follow these tips, the dark floor will decorate any room, even a closet or pantry.

The cream board is not inferior in popularity to the colors described earlier, as is, incidentally, a lamella, resembling chocolate. But the colored parquet board is suitable for light and for dark rooms. But most often it is mounted in children's rooms.

Lamella can be with a picture. It costs a little more, but it looks better from an aesthetic point of view. Patterns, imitation of the “French Christmas tree”, longitudinal laying of parquet - this is not all that can be offered by manufacturers to the buyer’s court. What to choose - classics or exotic golden oak, only the consumer chooses.

What characteristics to pay attention to?

In most cases, buyers when choosing floorboards pay attention to the price tag and colors. And this is not surprising, because if the product is more expensive than the amount that the consumer has, then he will not take it. And at the same time it is impossible to force him to buy a building material that he didn’t like But these are not the characteristics that need to be paid attention to.

When choosing a dark lamella it is necessary to take into account that care should be taken for it. Sooner or later, the protective layer will be scratched.On a dark background, the defects look more noticeable, unlike the light one.

As an alternative to the glossy coating can be advised frosted. Some manufacturers use oil - on it defects are less noticeable. Expensive copies, having from two or more drawings, pass the stage of brushing. Such a lamella is less susceptible to mechanical stress, since brushing is a process of deliberate “damage” to the product. Most often, an oak board is exposed to this, it has grooves with which scratches are perfectly combined. An uninitiated person will not even understand right away, in front of him is factory treatment or accidental mechanical damage.

Minor damage practically does not stand out on exotic woods. It is very important that the exotic does not pass the stage of toning. In this case, the dust on the exotic lamella will mix with the pattern and will not be reflected. So, the inconvenience to uninvited guests can be avoided.

If the parquet board has passed the heat treatment stage, then it becomes more resistant to temperature and humidity variations.But at the same time, some varieties of wood used under the action of ultraviolet during the operation can change color.

Classes of wear resistance of the floorboard depend on the methods of cutting raw materials used in production. Widespread radial and tangential cutting methods. The best indicator of wear resistance has a parquet board made in the first embodiment. At the same time it turns out building material from high-quality wood, without the inclusion of "weak" areas. This, together with other layers, leads to the manufacture of a durable product that will last more than one year. But the radial cut only affects the color and parallelism, as opposed to tangential. It adds a certain non-repeating pattern to the product.

Wear resistance for products manufactured in this way is lower. But the top layer can rectify the situation if the manufacturer uses wood with a good coefficient of hardness for its production. By the way, it is the thickness of the face layer that is responsible for the service life.

Rustic cut is used in the economy segment. Probably, it is not necessary to paint that such a product is most susceptible to deformation.It includes only cheap wood samples. therefore for "balance" it is desirable to choose a single plank floorboard.

On sale, basically, there is a three-layer board. In the first years, double-layer dies were produced, but manufacturers quickly realized that it would not be possible to hold onto the building materials market with such a product. It quickly fell into disrepair. The Swedish company, on whose technologies this building material is still produced, was able to correct the situation.

Styling methods

For the installation of any floor requires certain tools, is no exception and laying floorboard. First of all, you need a jigsaw. To do this, the usual household jigsaw will fit perfectly, but if the professional version is at hand, the work will be done faster.

Alternatively, you can use a hacksaw for metal. Unfortunately, Wood saw for this operation will not work. The fact is that its teeth can damage the product. Remember that the cut should be done not from the front layer, but on the contrary, from the bottom of the board. With this option eliminates the possibility of removing the protective layer.

Depending on the locking connection, a hammer or mallet may be required. If you use a heavy tool, the hand will quickly tire, and if you carelessly strike the lock, you can break it. Remember that it is advisable to use a plastic bar for punching, it will not form unwanted defects - chips, cracks.

A parquet board, like any tree, with temperature and humidity variations can expand. In order for the floor to “not float”, a small indent from the wall is surely made. Wedges are used for this procedure. A metal bracket is needed to secure the last lamella.

Measuring tool - a tape measure, building level and the square must be at hand. Additionally, you may need a pencil and marker.

Installation of floorboard made floating method, on logs or using glue or nails. In recent years, the first method is most often used. This is due to the fact that you can lay the board in both small and spacious rooms.

Glue when laying is almost never used. Such work takes a lot of time and effort.Correctly lay the board can only patient specialists.

Fixation with nails or screws is most often used when mounting a thick plank, and even as an addition to the lock joint. But on the logs often lay the board in country houses. Lags play the role of a subfloor, in this case a concrete screed is not needed. Sheets of plywood or cork are used as the substrate.

How to lay the floorboard by yourself, see the next video.

Top Brands Rating

In this section, manufacturers whose products are most in demand in the building materials market will be considered. The rating is based on the opinions of installers. After all, they can appreciate this or that building material. The sellers have also contributed, because who, if not they, know which floorboard is in demand.

The unconditional victory was awarded to the manufacturer who first presented the floorboard to the public in the 40s of the last century - this Swedish company Kahrs. In the mid-50s, it was this manufacturer who began to varnish his product, and in the 60s the engineers worked out the wear resistance.For more than half a century, Kahrs has been setting the direction vector for other manufacturers.

Yes, and it was this company that was the first who refused to use the adhesive method of laying floorboard when she released building materials with a castle joint at the end of the last century. The floorboard from the company Kahrs is not afraid of either moisture, or dust, or specks. Thanks to the seamless locking connection, the garbage does not accumulate, since there are no joints.

To this we can add that the products of this company are environmentally safe. The floorboard does not emit formaldehydes - substances harmful to human health. After all, their couples can lead to allergic reactions, and in advanced cases and to diseases of the upper respiratory tract.

Kahrs is the only company that received a rating of 10/10. This is due to the fact that the manufacturer offers a huge number of collections made of teak, oak, ash. This list may be supplemented by cherry, yatoba. All wood species and not list. The face layer consists of safe varnishes and oil or wax processing. Therefore, laying floorboard can be safely carried out in children's rooms and kindergartens.The thickness of the board of the products offered can be from the lowest - 7 mm to almost unimaginable 30 mm.

German manufacturer Haro Parquet, although it did not reach the leader a little - the rating is 9.9 / 10, but by right it occupies the second place. This company is known in Germany for more than 150 years, it exports its products to almost a hundred countries. It is one of the leaders in the European market.

Their products are premium, respectively, hence the high price of the product. But for this money, the buyer receives high-quality products that do not contain harmful impurities and toxic substances. Depending on the color, the front protective layer may consist of varnish, oil or wax.

Haro Parquet collections include floorboards of various sizes, patterns and colors. Additionally, at the production stage, the building material undergoes brushing, heat treatment and whitening. As a bonus, accessories and protective equipment are attached to the floorboard. Operational period, like its predecessor, is thirty years.

Second place with the company Haro Parquet shared Austrian manufacturer Weitzer Parkett. His rating is equal to the same 9.9 / 10. In ten years, this company will celebrate its bicentennial anniversary.In addition to the magnificent floorboard, the company produces other wood products.

The products of this manufacturer is environmentally friendly. By the way, Weitzer Parkett cooperates with the society for the protection of the environment. The company was the first in the market who was able to offer a product to the consumer that does not allow ambient noise into the room.

Weitzer Parkett has special certificates that guarantee the safe use of products in kindergartens. From which we can conclude that for children's rooms, these products are perfect.

This is one of the few producers who grows valuable tree species on their own land - oak, walnut, pear. The floorboard can be laid in rooms with high humidity, because the products are moisture resistant. Installation of this board can be carried out with the use of glue and with the help of locking joints. About three decades, the product will last guaranteed.

On the fourth line of the rating was a joint Russian-Swedish company Tarkett with a rating of 9.2 / 10. Perhaps this is the only company in the domestic market that is most popular.

The parquet board under the Tarkett brand is suitable for a premium class, and for the economy segment, products are manufactured under the brand name. Sinteros. If products for wealthy people are produced in European factories, the economical version is produced in Russia.

All products have certificates of quality, suitable for both domestic and commercial use. Great combination of price and quality. The parquet board is covered with a water-repellent compound, has a patented lock joint and will serve with proper care for more than twenty years.

Reviews

With regards to customer reviews, they also add to the rating of the joint Finnish-Russian production - Upofloor, known in the domestic market under the brand name "Karelia". Co-production appeared at the beginning of the millennium, during which time many collections were presented on the construction market, both in the premium segment and in the economy class.

A few years ago, the company became part of the concern. Kahrs - It is the undisputed leader of the rating and the founder of this segment. Due to this, the joint venture products began to be produced according to European standards, and the collection line was expanded.

The floorboard under the brand "Karelia" has good durability, moisture resistance, environmentally friendly. With a locking connection even a non-expert in installing floors will cope.

According to consumer reviews, the floorboard of this company can last up to twenty years. And if you properly care for her - even more.

Lamels from the company Boen known in the domestic market for more than a decade. Buyers appreciate these products for reasonable price and good quality. The proposed line has dozens of collections, new items appear every year. The Norwegian board will serve about 26 years.

Polish-Ukrainian joint venture Barlinek afford and wealthy, and less wealthy people. Presented about a dozen collections for every taste and color. The use of not only hardwood and coniferous trees, but also exotic - wenge, merbau, yatoba - distinguishes this company from the rest. Board, released in the factories of Vinnitsa, perfect for bedrooms and living rooms.

Not to mention about the domestic manufacturer Amber wood. For more than ten years, the Russian company from Dalnerechensk seized, in the best sense of the word, the building materials market.

Using solid wood, such as oak and ash, a company from the coastal region was able to present to the public a durable product at an attractive price. This is due to the fact that wood grows in the place where the plant is located, which means that savings on logistics allows the manufacturer to adjust the cost of goods. The board, issued from a domestic plant, will serve in a city apartment or in a country house for about ten years.

How to choose?

A few years ago, when I had to choose a floorboard for an apartment, buyers paid attention only to the appearance. To buy it for the kitchen or in the bathroom and the speech could not be, because the first copies did not differ moisture resistant indicators.

Today it is easier to choose. Firstly, there were more construction stores, and secondly, high-quality products appeared in them. Large assortment allows you to choose a product both in quality, and in price, and in attractiveness.

Today it is easier to choose. Firstly, there were more construction stores, and secondly, high-quality products appeared in them.Large assortment allows you to choose a product both in quality, and in price, and in attractiveness.

Remember that the most wear-resistant flooring board is produced from exotic tree species. But for domestic use there is enough building material made from oak or ash. Yes, and in the interior of such a board looks no worse than the exotic wenge or merbau. The main thing is to pay attention to the manufacturer, composition, as well as the following indicators:

- Moisture resistance. On the packaging of any floorboard you can always find certain icons. In particular, water protection says that such a product can be laid in kitchens or in the corridors. Of course, it is not necessary to fill the floor, and the strait lamella will endure without damage to the appearance.

- Density. For domestic use, experts recommend buying a board with a thickness of at least 21 cm, then it can be stated with great confidence that it can withstand the weight of large furniture and is not deformed.

- Protective layer. A well-known fact - the floorboard is treated with either oil or varnish. Lacquered building materials are advised to install in areas where possible interaction of the floor with water.For the rest of the premises is enough building materials, treated with oil or wax.

- Wood species As noted earlier, the most viable are oak, ash, teak. They can also be laid in the kitchen or in the hallway, since mechanical damage is less “sensitive” for them, unlike soft rocks.

- Chamfer. Products with a facet can be easily dismantled, and from this it follows that in case of mechanical damage they can be replaced without serious consequences.

- Smoothness. For different styles, either a smooth board or with rough edges is selected. Some specially choose the floorboard with embossed pattern, because on such a product scratches are less noticeable.

How to care?

Before you take up a rag or vacuum cleaner you need to find out what material the protective layer consists of. It can be oil-wax or varnish. The first variety is not characteristic of acrylic film. To restore the "oil" protection, it is enough to treat the damaged lamella with a grinder and apply a new layer of oil.

Wet cleaning of the oil lamella is carried out with the help of a damp cloth and usual soap solution.It can be made by hand from the remnants of laundry soap. If the cloth is not carefully squeezed out, water can get into the cracks and the product will become unusable. In no case should the wax protection be removed, only dry cloths are used. When using household chemicals are likely to change the color of the slats. The varnished coating is cleaned with special means. Some are sold in finished form, and some need to be diluted in water.

If the apartment has pets, they can ruin the floorboard. In this case, you can use either a polish or acrylic varnish. After drawing the parquet board will get an original form.

Spectacular solutions

This section presents photos and examples of the floor, where the flooring is used, as well as its placement on the wall in the interior.