DIY parquet flooring

One of the most important components of the design of the room is the floor covering. Very often buyers stop their choice on the floor. With this floor, the room turns into a cozy and safe corner of the house.

In this article you will learn about the step-by-step instructions for laying parquet with your own hands.

Coverage Features

The word "parquet" in French means "floor of unpainted boards." He appeared in the XXIII - XIV centuries. Since then, many centuries have passed, and the need for it has not dried up. The most valuable and highly artistic is the Russian parquet of the XVIII and XIX centuries.

The creator of the parquet is Gustav Cher, who works in the company. Kahrs. This construction company is the leader in parquet production.. The floorboard is made from both expensive wood and not so valuable, which is used to produce the substrate.

Mechanism of manufacturing floorboard:

- Making the front layer. At this stage, expensive woods are cut into slats of the required size. With the help of a milling machine they are customized to a regular geometric shape. Next, the lamella is covered with glue and it turns out the front layer. If necessary, you can conduct heat treatment, planing and bleaching.

- Manufacturing substrate. The cut board from less valuable breeds of wood is cut. For the third layer, material from coniferous veneer is used to maintain the structure.

- At the third stage all layers are glued together.. The second layer is supplied with fastening.

Advantages of a parquet natural covering:

- made of natural materials;

- wear resistant;

- easy to repair;

- environmentally friendly and safe;

- various designs are applied in the design;

- there is no static electricity.

Disadvantages:

- very sensitive to moisture;

- high price;

- complicated styling process;

- requires extra care.

In order for the parquet to serve for a long time, it should be selected according to the following criteria:

- Any parquet must have a certificate of quality. This is the key to durability.

- Do not buy cheap flooring.This may incur additional costs.

- Humidity floorboard - no more than 10%.

- A good parquet has a ringing sound, if you knock on it.

- Parquet has a natural smell. If there is an extraneous flavor, this means that the parquet was treated with chemical compounds. Its service life is much less.

In modern building stores you can find a huge selection of parquet from different types of wood.

There are several types of parquet:

Piece

The most popular and common form. It is made from natural materials. It is made of plates with grooves and ridges, going into a castle and turns into a single canvas. It has a classification by image cut - select, natur, guest, classic, station wagon, antique.

Its advantages:

- has a long service life;

- environmentally friendly and safe;

- possesses warm and sound insulation;

- can be repaired many times;

- has a large selection of pattern.

When choosing piece parquet, it is necessary to take into account the climatic conditions of the room. From this will depend on his life.

Parquet is made from various tree species:

- Oak flooring - durable, moisture resistant, has a beautiful pattern. Its disadvantage is that it darkens over time.

- Beech parquet has a yellowish or reddish color. The downside is that under external influences is easily deformed.

- Maple parquet very similar in quality with oak, the same solid. It has a white tint, but yellow when used.

- Cherry parquet brown, well machinable.

Typesetting (mosaic)

The coating has shields with sets of different lamellae with different shades. In the complete set the floor is a mosaic.

The mosaic set is divided according to the joining method and the type of edges:

- with a fold;

- with oblique groove;

- on solid rail;

- on the soft rail.

Shield (modular)

The parquet is made of two layers - a square shield of boards or fibreboard and small planks of high-hardwood species. The main image is a square or its derivatives.

The basis of such floor is divided into the following types:

- framework;

- rack;

- the basis from TsSP or DSP;

- two-rim.

Palace (artistic)

The most expensive view. For such a wooden coating uses a huge number of bends and different types of weaves, the general view is not just a drawing, but an exquisite creation.

For artistic parquet use a huge number of different tree species. It is usually made in large rooms (palaces, museums).

Massive

Slats are made of solid wood. Parquet is very similar to the piece, but differs in size. The size of a massive plank: width - from 8 cm, length - up to several meters, thickness - 1.5 cm.

Floorboard

The lower row of boards is coniferous wood material, the upper one is solid wood, which easily tolerates changes in temperature and humidity.

Vinyl

It has a beautiful design, quickly fit. Made from homogeneous polyvinyl chloride - 80%, the remaining 20% - various additives (pigments, plasticizers, stabilizers, natural quartz, vinyl).

There are several types of vinyl floor covering:

- tiles connected with special glue;

- tiles that have a locking system of attachment and are connected with glue or without it;

- tiles with GripStrip adhesive technology are the most common type.

The unique properties of such a coating:

- long does not give in to wear and mechanical damages;

- waterproof;

- anti-slip surface;

- antibacterial coating;

- resistance to fire and chemistry;

- noise and heat insulation;

- esthetics;

- simplicity and ease of installation.

When laying the boards are glued to the base, therefore it is also necessary to choose high-quality glue. At the same time it is necessary to take into account the characteristics, types and dimensions of the floor material. The quality and durability of its operation depends on it. Parquet glue is the main component for joining wooden planks to the base of the floor.

There are several types of glue:

- Dispersion glue Made on the basis of water with the addition of synthetic resin. Therefore, it is environmentally friendly and non-toxic. In the store you can find a large selection of this mixture, but it differs in the percentage content in the composition of the water. Adhesive mass is used to connect moisture-resistant plywood under parquet, otherwise less durable types of wood (apple, pear, beech, alder) can begin to rot and deform.

- Solvent glue. The mixture contains some water. It is used for gluing slats of any wood species. It is forbidden to work with such a composition near an open flame, as the liquid on solvents is explosive and fire hazardous.The room should be constantly aired, because when the glue hardens, substances dangerous to the body evaporate. There are two types of glue - alcohol and petroleum based.

- Polyurethane. There are two main groups of polyurethane material - it is one-component and two-component. Hardening is accomplished by combining the glue with moisture in the air. This type of glue does not violate the protective and decorative layer of parquet, therefore it is used to join prefabricated wooden flooring.

The advantages of such glue are elastic, do not shrink, have a low price. Manufacturers advise to use this glue when laying on a concrete floor. Minus - drying time comes to 4 days.

- Two component adhesive - the most common for parquet. This mixture is sold in convenient buckets. In the container itself is the base, and in the lid - powder of a certain composition. Glue is obtained from the dry component and the emulsion by mixing, then during the day there is a process of hardening. This mixture is stronger than other compounds. It is used to connect wooden planks on any floor bases - wood, concrete, metal. Reliability of fastening is not affected by wood species and sample size.The remedy is toxic and dangerous. In case of contact with skin, severe pain and chemical burns appear.

High-quality adhesive mixture should have the following properties:

- firmly and permanently fix the coating;

- after drying, the mixture retains its elasticity and elasticity, which is important when the boards expand with temperature and humidity variations;

- the composition should be the minimum amount of water;

- Composition should be safe.

Mounting methods

All work begins with the preparation of the premises, and this is cleaning the floor from debris and dust, checking the rough base for cracks and grooves. Parquet boards can be laid on plywood, concrete and wooden floors. If there is already an old parquet, it must be dismantled.

The method of installation depends on the type of parquet and the type of foundation:

- Floating. It uses a thorn-groove system. This method is not suitable for large rooms. Advantages of this method:

- The mount does not loosen during use;

- Temperature drops do not affect strength;

- Quick repair.

- Adhesive. A fairly durable way of joining, but repairing the parquet is difficult at the same time.

- Mechanical. Stowed with nails and screws.

- Combined. Mounted with fasteners and glue.

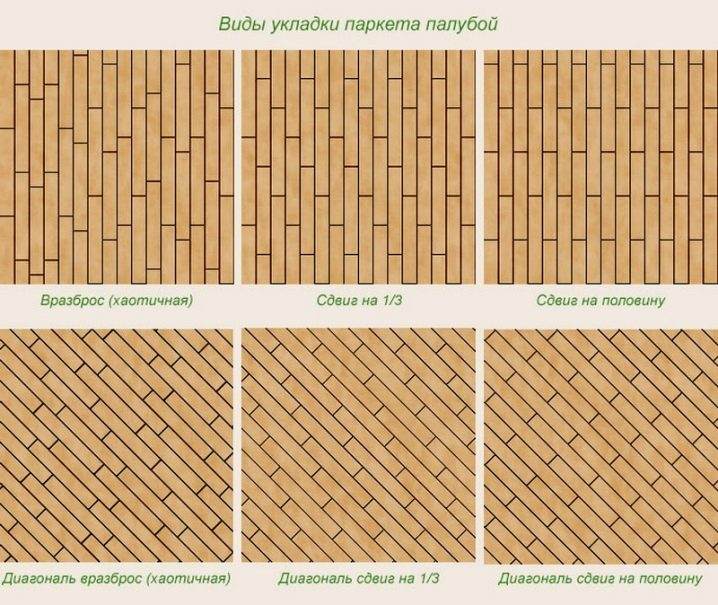

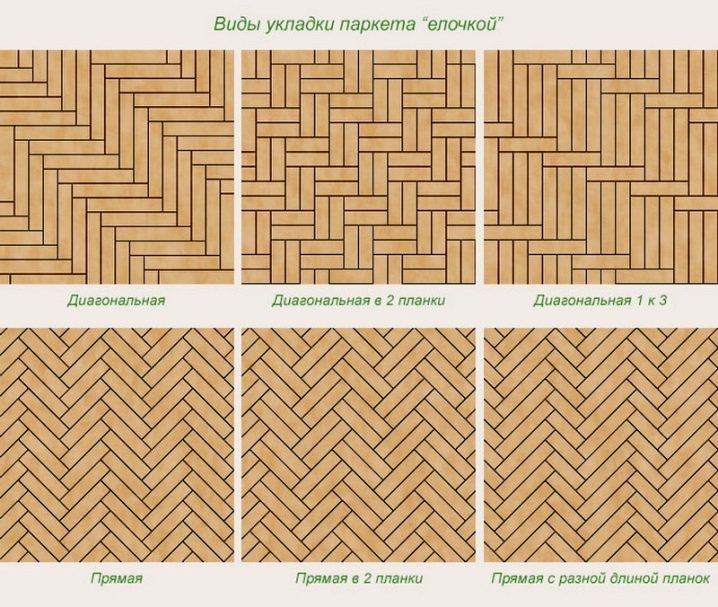

There are several common patterns for laying parquet:

- Deck If this technology of laying is chosen, then for a reserve it is necessary to have 5% of a parquet. It happens:

- symmetrical - shifted by 1/2 and 1/3 of the value of the next;

- diagonal - a different angle of inclination is applied;

- chaotic - styling is done without symmetry, that is, arbitrary.

- Herringbone - With this installation will require glue, the remains of the slats - 4%. Varieties of such styling:

- according to the number of parquet - single, double, triple;

- in the direction - directly or diagonally;

- Herringbone with "inserts."

Square or braided - a modern way of laying. You can use several types of trees.

Necessary tools and materials

Before starting work, you need to prepare in advance the tools and materials that will be required for laying your own parquet.

These include:

- parquetthat will fit;

- gluethat is suitable for the selected flooring. The most common is two-component. It is used for laying piece and mosaic parquet;

- jigsaw for fit sizes;

- hammer and nails for mounting baseboards;

- marker and tape measure for marking;

- lining bar for adjustment, protection from chips;

- restrictive wedges for gaps between a wall, a door;

- metal bracket ideal for adjusting the plank to the base coat;

- pneumatic gun for installation;

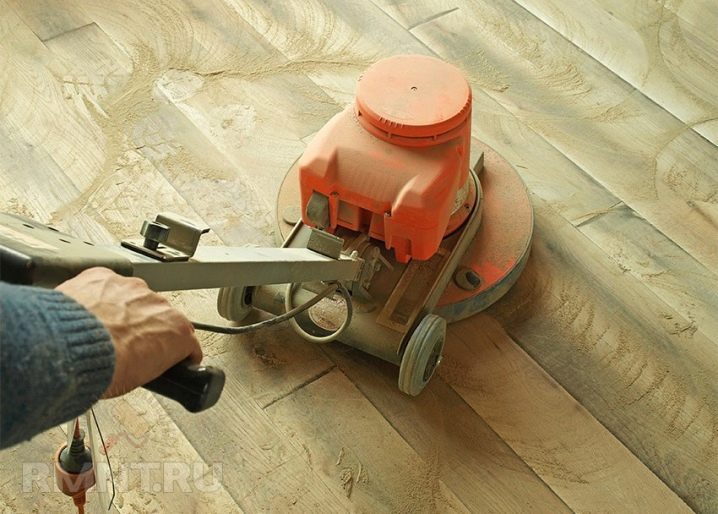

- sanding machine to make the floor look presentable;

- mastic to preserve the integrity of the wooden coating.

Preparatory work

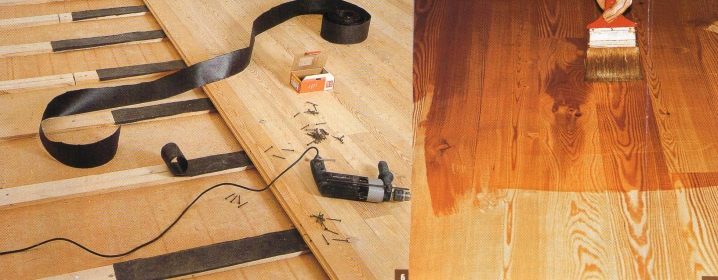

To parquet served for a long time, you need to perform a number of preparatory work. Basically, it concerns a rough base - it is a concrete screed, wood flooring and plywood. At the same time the floor should be smooth, durable, without cracks and depressions. Wooden floor base should be inspected on rotten, failed and poorly bonded floorboards. If there are such boards, they should be replaced or fixed with self-tapping screws..

Swings and irregularities can be puttied with a mixture of PVA and wooden sawdust. After eliminating all the shortcomings is made of plywood substrate.

The most popular base is concrete. It has long served and the most durable.It also requires checking the floor for cracks, grooves and drops. You can eliminate them using a self-leveling mixture. If the old concrete has crumbled, it must be removed and re-filled.

During installation, it is necessary to take into account the level of humidity in the room - 40-60%, temperature - 18-220°WITH. This is due to the fact that the tree is very sensitive to the microclimate and the deformation of the slats is possible. We also need to know the moisture content of the concrete base. If it exceeds more than 4%, then it is necessary to make a waterproofing barrier. Polyurethane primer recommended.

If you lay the parquet on a warm water floor, then experts advise to use the floating floor method using brackets, which are necessary to connect the planks to each other. Brackets regulate the expansion and contraction of wood with changes in humidity and temperature. Parquet rests on the base without any fasteners. If the floor is old parquet, then it must be removed. It may be infected with fungus and spoiled. Before it is necessary to dismantle the baseboards and sills. It is very difficult to clean glued parquet, for this they use a chisel and a hammer.

Removing the old parquet as follows:

- Hammer tapping the surface of the floor and find a place where the slats depart. From this place they begin to disassemble the parquet.

- If the dies do not depart, then the disassembly process should be started from the side of the floor, which is opposite the window.

- At the junction of the panels it is necessary to drive in a chisel, pry them and then knock them out. The whole process is done with all coverage.

The technology of parsing the shield parquet is similar to the previous one. To do this, put a little more effort, since the shield from the adhesive mixture is much more difficult to tear off.

If only part of the parquet has failed, it is necessary to disassemble this section. In order not to damage a part of a good floor covering, it is necessary to cover it with cardboard and film, attaching them with construction tape to the surface. Disassembly is also done with a chisel, only very carefully.

Step-by-step instruction

For laying parquet does not necessarily call professionals. All work can be done by hand. To do this, you must correctly follow the step by step instructions. The most important phase of laying is the preparation of a rough substrate under the floor.. It is necessary to check the basis for the existence of flaws. The floor should be perfectly clean and level, without cracks and depressions.

There are several options for laying floorboard with your own hands on a different basis.

If the floor is concrete, it must be waterproofed, that is, covered with a special diffusion membrane or film. The docking of the membrane is done with an overlap of 20 cm and fixed with construction tape. On the walls of the membrane lead to 15 cm and tape attached. Next, the floor is poured with a self-leveling mixture with a thickness of not more than 5 cm. This is the base for waterproof plywood.

Plywood has its advantages:

- protects parquet boards from distortion;

- levels the floor;

- gives good heat and sound insulation.

After the screed has dried, it is coated with a primer and covered with plywood, which is at least 12 mm thick. Plywood sheets are cut into 75x75 cm squares. This will protect the parquet from shrinking distortion and will serve as the foundation for connecting the boards.

After all the manipulations, the screed is covered with glue and plywood is laid on it.which is strongly pressed and fixed with screws.

It is necessary to make gaps between the wall and plywood up to 2 cm.Between sheets of plywood it is necessary to make a gap of up to 4 mm. This is required so that after the expansion part of the plywood does not interfere with each other.

The next type of base - floor on logs. A waterproofing film creeps onto the concrete, after which the logs are laid (bar 50x50 or 50x80 cm) with a step of 35-40 cm and connected with angles and dowels. Next, you need to lay the flooring of plywood. For the connection are taken screws. Laying parquet can be on a wooden floor. To do this, it is necessary to make an audit of the coating for squeaks, dips and other defects, only after that the floor is polished.

If the base is a concrete screed, all work is performed as follows:

- the floor is polished to a completely flat state;

- dust and other debris are removed; special attention should be paid to corners and places near the walls;

- the primer is applied with a roller and all areas are coated;

- The sheets of the insulating substrate are glued to the butt joint and smoothed by hand. Next, you need to walk on the floor with a heavy roller for tighter fixation.

The article mentioned the lining material (substrate) several times, which is an important component for working with parquet.

There are several types of substrate:

- cork material compensates and aligns the base, if there are small irregularities;

- the cardboard is impregnated with water-repellent compositions and is ideal for underfloor heating;

- coniferous pressed rolled material has good thermal and sound insulation, but does not serve for long;

- material from cork and bitumen has a high level of heat and waterproofing, but it is forbidden to use it with warm floors;

- three-layer Tuplex consists of two layers of polyethylene film, between which there are polystyrene foam balls. This substrate is intended for leveling small base defects. Its main purpose is to create a ventilated gap under the finish, to remove moisture and to level out minor defects of the base;

- Foamed and extruded polypropylenes have good thermal and sound insulation. But such a substrate has a short lifespan, so experts do not recommend using it under parquet.

After the base is ready, you can begin laying parquet. There is a certain technology of working with parquet flooring.

For laying “herringbone” it is necessary to use rectangular parquet floors, which are laid at an angle of 90 degrees to each other, and to the wall - 45 ° С. The pattern of the entire floor depends on the first two rows. They set the direction of the entire floor covering. From them it is necessary to stretch the ropes for accurate reference. For laying parquet in this way, you should use a special glue.

If you use the "floating" method for laying piece parquet flooring, the work begins from the corner of the longest wall from left to right. It is necessary to leave a distance of 6-7 mm between the wall and the first line of the floorboard, using mounting wedges. The second row is inserted into the grooves of the row already laid at an angle of 20 ° C and snaps into place. For good fixation use a rubber hammer.

In the adhesive method, glue and small nails are required, respectively, to fix the parquet. The first line of slats is glued to the floor with a distance of 10 mm between the wall. Glue must be applied to the base and the ends of the parquet, bonding together. Boards are strongly pressed to the floor, excess glue is removed with a dry cloth.It is necessary to let the glue dry, only after that to continue the work.

After the parquet is laid, the extra substrate and sound insulation that is visible is removed. The wooden plinth is installed with the help of clamps. The plinth is chosen in the color of the floor or wall, while it is also necessary to pay attention to the size and texture.

On the market, you can see wooden baseboards with hidden connection to the brackets and cable channels. Skirting boards should be made of the same type of wood and purchased from the same lot.

When done all the work with parquet and baseboards, the floor is polished. It is necessary to remove defects and glue.

In the first and in the second stage, grinding is performed with large grain, in the third - fine. All manipulations are carried out with a grinding machine. After the floor is removed from dust and debris.

If necessary, putty gap. After it dries, the extra putty is removed. Then the parquet is varnished to protect it from moisture. It is desirable to apply varnish from 3 to 9 layers.

Tips and tricks

- all work must be done correctly, do not rush and be careful;

- it is necessary to prepare in advance for laying the floorboard - choose the method of laying, direction, draw a diagram, buy the necessary material and tools;

- for better grip, use the right glue;

- installation of parquet is undesirable at the beginning or at the end of the heating season;

- The parquet should get used to the climate of the room in which it will be installed, therefore, before installation, you must give it 48 hours just to lie in the room;

- if the glue method was used, the floor should be dry, and subsequent work should be done in a week;

- parquet must choose well-known manufacturers;

- you should not make often wet cleaning, the parquet is afraid of water; You can simply use a vacuum cleaner or a well wrung out cloth.

- Professionals do not recommend laying parquet on a water floor, as if the pipes break, the parquet can be severely deformed. Reliable construction in this case is an electric or infrared floor.

- Removal of various stains:

- blood can be removed with a damp cloth;

- black stripes from the shoes are removed with nylon;

- Wax stain must be frozen, then it is removed with a plastic spatula.

How to lay the parquet with your own hands, see the next video.