Putty for parquet: features of choice

Currently, there are many options for decorative flooring, one of the most popular is wooden parquet. This material is not cheap, requires a certain care and appropriate protection of the surface, which will help a special mortar - putty.

Covering the floor with parquet, it is necessary to understand in detail what constitutes a putty for parquet, taking into account the peculiarities of the choice of this mixture.

Purpose

Laying parquet slats is a delicate process that requires certain skills and abilities, but even on a perfectly positioned surface, undesirable gaps may appear over time. This is due to shortcomings in the manufacturing technology of this material, as well as with the shrinkage of wooden components during operation.

Recreating the original look of the flooring is not a very easy process, but it can also be done if you use such a building material as putty.Special skills and experience in this matter will not be needed, you can even do all the manipulations with your own hands.

When carrying out repair work on the parquet, all gaps formed should be repaired with a repair mixture specially designed to eliminate minor surface defects. The frozen mass of putty not only improves the decorative function of the flooring, but also helps to increase its service life.

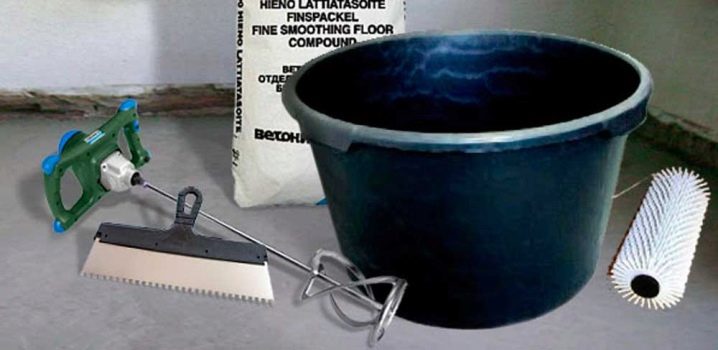

When closing up unwanted crevices putty is applied at the grinding stage. When eliminating various defects, chips, cracks, stains you must first clean or scrape the surface, then you need to level all the flaws with a putty and then varnish the surface.

Filler requirements

There are several general requirements that all types of fillers must meet, regardless of their composition:

- Sufficient elasticity. This feature helps the putty evenly distributed over the surface of the floor covering and carefully fill all the slots.

- High adhesion to wood guaranteed to provide a long period of operation of the coating without swelling and peeling.

- Uniformity of composition eliminates the presence of any third-party impurities or individual coarse particles that can cause mechanical damage to the coating.

If the mortar is chosen to level the flooring outside the room, for example, on the terrace or in the gazebo, then additional requirements must be placed on this putty:

- Resistance to temperature and frost resistance. This factor affects the preservation of quality coverage at any time of the year.

- Moisture resistance will help protect the wood coating from direct penetration of precipitation.

- Drying speed - an indicator on which the duration of finishing work in general.

Putty intended for interior work must have other characteristics:

- environmental friendliness and complete safety for health;

- antiseptic and bacteriostatic features that help keep the cover from breeding various bacteria and fungi;

- increased resistance to possible sparks from an open flame (area near the fireplace).

Special chemical additives - modifiers that make up the putty,ensure the fulfillment of the necessary requirements depending on the operational purpose of the building mixture.

Species

Currently, there are a large number of different putties for processing wood surfaces. They differ in the constituent components.

On this basis, putty mixtures can be divided into several main varieties:

- solvent based putty;

- acrylic putty mixture;

- oil;

- polymer;

- homemade mix.

The solvent-based putty has a number of positive properties - it is fast drying and easy to work, which significantly reduces the laying time. The main component of this mixture are fine sawdust.

Acrylic parquet putty is an indispensable material for the elimination of minor defects. This mixture also has a number of positive characteristics, one of which is environmentally friendly. Due to its good elasticity and high resistance to mechanical stress, it is successfully used for grouting parquet flooring.

The main substance - acrylic - significantly increases the water-repellent properties of wood, respectively, increases the service life of the parquet.

The main components of the oil-based putty are chalk and water, it is applicable to any type of wood (Oak, pine, birch, maple - the most common wood species for the manufacture of wood flooring). This mortar has a very long service life, but due to the presence of oil in the composition, the disadvantages include a long drying period, which reduces the speed of repair of the coating, although it is quite convenient to putty with this solution.

Polymer blends also belong to environmentally friendly, they are applicable to any kind of wood, except cork coverings.

The main advantages of polymer fillers include:

- good performance;

- high level of coating protection;

- ability to resist cracking and sagging after a quick drying period.

Self-made putty is considered the most suitable in color.

It can be prepared in several ways, but the most practical is a mixture that includes:

- liquid soap;

- drying oil;

- animal glue;

- turpentine;

- liquid desiccant;

- a piece of chalk.

Mix all the ingredients in hot fat to the consistency of thick cream,The resulting composition is applied in a warm condition. The dried mixture is sufficiently transparent, which allows its use on all types of parquet.

How to choose

When choosing a putty for parquet flooring, there are several important points to consider:

- The working mixture must remain plastic for a sufficient period of time in order to qualitatively fulfill its main purpose.

- The composition should be uniform, without lumps.

- After drying on the surface of parquet boards should not be cracked.

- The rate of hardening should be moderate.

- The mixture should be compatible with the finishing paint solution (preferably when the putty is colorless).

It is desirable to first purchase a putty in a small amount for the sample, so that in the future, in the event of positive results, the material is purchased in the right quantities. It should be understood that the spackling mixture used in living rooms may differ from the mixture for bathrooms, dining rooms or terraces.

Manufacturers

At the construction market at the present time are presented all kinds of putty mixtures of both domestic and foreign manufacturers.Any parquet putty has its pros and cons. Going to the store for the purchase of grout material, it is worth to start to analyze some of the most popular samples.

Tikkurila Company For many years, is considered a leader in the manufacture of putty materials. Brand products have good adhesion and performance.

Swedish firm "BONA" deserves special attention and is considered a good example of a water-dispersion composition.

German putty "Loba" In addition to good performance, it also has an affordable price. Universal Uzin fillers are suitable for every type of parquet. Kiilto Gap is a solvent-based spackling compound that is much stronger than aqueous putty.

Of the products presented by domestic companies, the mixtures Extra and Raduga have stood out; among the masters, trowels enjoy success Lakra and budget line from EUROTEX.

Restoration of parquet with putty is shown in the next video.