Scraping parquet with his own hands

Parquet flooring is popular at all times. The material is associated with the warmth and comfort of the home, the classic noble style.

Despite its durability and durability, the tree needs periodically carried out restoration. The operation is necessary, since any floor covering dims, scratches, and is squeezed out during operation. For these purposes, the technique of parquet cycling was developed.

What is scraping parquet?

The process of scraping parquet is the removal from its surface of a thin top layer with the help of special equipment.The operation allows you to return the floor smooth, eliminate defects in the form of scratches, chips and dents, eliminate the creak of floorboards.

Cycle - the name of the grinding machine, which was used to name the process itself.

Types of scraping

Scraping can be done in several ways.

Manual

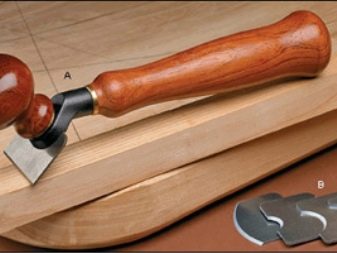

The method was common before the advent of mechanical devices. He requires great effort and time from the master. Manual cycle is a sharpened metal plate, bent at an angle of 45 degrees to the handle. It has different forms. As a rule, use a tool about 5 cm wide.

Grinding can be done with coarse sandpaper. But this type of work is so tedious that it is not recommended for large areas.

Semi automatic

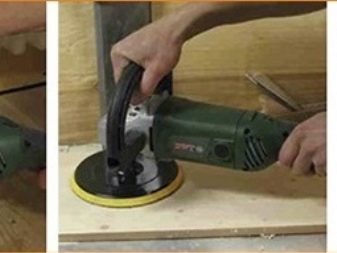

In this case, various devices for hand tools are used. For example, Bulgarian grind. To do this, glue on her disc sandpaper. In addition, belt and rotor-orbital grinding machines are used.

Mechanical

The method appeared in the 70s with the development of a special machine equipped with knives.With their help, the top layer of the floor covering up to 16 mm thick was cut off. In connection with the advent of the new grinding equipment, the process has become more careful, better, less harmful for the parquet. For mechanical dust free scraping It is better to use the device with a built-in dust collector.

Features of works with different types of parquet

Polishing the parquet floor is made in the following cases:

- New assembly of grooved slats before the subsequent registration. Scraping new parquet flooring is done in two stages. The first is carried out on a slightly damp floor, the second is carried out finishing cleaning a dry surface.

- Restoration of the old floor. It is worth resorting to the operation if the floor is heavily trampled and scratched, the parquet is stained, the varnish has peeled off and dimmed, the floorboards began to creak.

The difference between the process of scraping old and new parquet is that in the first case the minimum layer of wood is removed, since it is not burdened with varnish, stains and scratches.

Scraping is not advisable in the presence of the factors outlined below:

- There is no need to close the gaps between the strips larger than 5 mm, you need to completely change the specified area of the floor covering. Otherwise, you will have to return to it in the future.In the presence of severe damage resulting from various factors. These include:

- The height difference that causes the curvature of the slats. As a result, the floorboards are wiped by rubbing against each other.

- Damage to wood by wood sharpeners. Defect can be determined using ordinary woolen. If it effortlessly enters the body of the plate at an angle, then the wood is damaged.

- Deep scratches and cracks.

- Scraping was done several times. The thickness of the parquet does not allow for the restoration an infinite number of times. Allowed a maximum of 3 times.

- Flooding the floor with water, which caused the appearance of mold and mildew. Here you have to completely change the coverage. To check the humidity of the floor, you need to cover a separate area with polyethylene, firmly attaching it to the floor. The temperature in the room should be in the range of 20-25 degrees. If after a day on the film condensation appeared, then the tree is wet. It is better to dismantle it or correctly organize waterproofing.

The scraping depends on the material of the parquet. Hard wood will require considerable effort, while soft ones are easy to process.

The subtleties of processing oak coating

Elite oak parquet is characterized by a certain hardness of the wood, respectively, when processing will provide maximum resistance.

For high-quality grinding it is better to choose a scraper of the drum type with a nozzle from a special durable material. Leveling oak parquet requires the coarse coarse abrasive material.

When tinting and varnishing, remember the following:

- Oak wood changes its color over time; this is called staining. In this regard, the old parquet has almost black color.

- Wood has a high density, respectively, has a low degree of absorption of dyes. As a result, has a faded color.

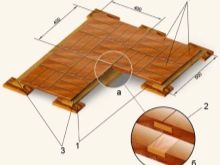

Shield parquet, unlike a piece, consists of modules in the form of shields, on which dies are pasted. Thanks to this structure, less time and effort is spent on laying the coating.

It is possible to scrape the wooden shield coating only 2 times, since the top layer is quite thin.

When working with panel parquet in advance, determine the thickness of the useful layer, that is, the distance from the outer layer to the lock tongue. As a rule, it can vary within 2-6 mm.Accordingly, the greater the thickness, the larger the granules of the abrasive material can be used.

As a rule, before scraping, it is recommended to take out all the furniture. However, large heavy items that do not move can be installed in the room. Therefore, the old parquet loop around their perimeter.

Stages of work

Before starting work, it is necessary to familiarize yourself with the recommendations of specialists, develop instructions for action for yourself, prepare tools and premises.

Instruments

You will need a grinding machine or the cycle can be manual and automatic. The second option is very expensive, so for the repair of an apartment or a private house is better to rent it. Vibration grinders, which are used for manual processing, are much cheaper than automatic equipment. However, they cannot provide a good degree of smoothness. Manual cycle can be useful for grinding floors in the corners of the room and around large furniture.

Machine for grinding drum or tape type significantly increases the speed of restoration work. Professionals say that such equipment is best used for the restoration of large surface areas.The tape parquet grinder equipped with a drum is available in two versions: with single-phase or three-phase drive. Models in most cases are equipped with a dust collector. Note the lack of uneven grinding, so it is recommended to use only for rough sanding.

Disc surface grinding equipment is one of the latest developments, therefore it is devoid of the drawbacks of its predecessors. The machine with disk nozzles is used for fine leveling the floor, as well as for sanding layers during varnishing.

Among other tools are needed:

- Corner boot-type machines are applicable to the treatment of hard-to-reach places in the room: in the corners, under heating devices, around solid furniture or along the baseboard. Modern models are equipped with garbage bags.

- The construction vacuum cleaner is mainly used for industrial purposes, it is not advisable to buy it for home use. It is better to rent or use a broom and a regular household vacuum cleaner.

- Nozzles for scraper machine.

- Bulgarian, drill.

- Screwdriver.

- Nails, screws.

Materials

You will need:

- Additional parquet strips to replace damaged.

- Sandpaper of varying granularity. For scraping it needs a lot, so the stock should be substantial.

- Putty wood in finished form. The composition is suitable either on a water basis or on a nitro-solvent. Experts sometimes independently knead a solution of wood dust, which remains during grinding.

- Spatulas for laying putty.

- Primer for wood.

- Brushes and rollers for applying a primer.

- Personal protective equipment: gloves, respirator or gauze bandage, glasses.

- Outdoor protective equipment: wax, oil, antifungal compounds.

- Decorative coatings: toning, stain, varnish.

Room preparation

Immediately before work you need to carry out the removal of furniture from the premises. If some objects do not move, then you can leave them in place, but pre-close the covers. Scraping - the process is very dirty, the dust will fly in all directions.

The plinth is removed around the perimeter. Sometimes it is left, but only in the case when it is impossible to disassemble without serious consequences. The floor should be washed first and then cleaned.As a result, the coating must get rid of dust, dirt and small debris.

It is recommended to secure the room, for which all the lying wires must be hidden in special boxes for communications or using electrical tape to lift them from the floor. If the parquet floor is in satisfactory condition, then the preparation is almost completed. It is enough to deepen the heads of the nails, so as not to damage the grinding machine.

Otherwise, you must first eliminate the defects of the floor in the form of drop-down strips, deep scratches.

Types of defects and their elimination

Allocate:

- Dips of individual slats in the floor. It is required to remove the damaged plate, clean the recess and put a new plate into it, fixing it with glue.

- Badly fixed parquet plates should be fixed either with nails or with glue. To deepen a hat into wood not less than 2 mm. If the strips were fastened in a hidden way, it is better to use glue.

- The creak of wooden floors arises from the drying and aging of wood. In this case, creaking floorboards are reinforced at the corners with thin nails. You can use another method: a wooden pin, covered with glue, is driven in between the parquet plates.

- Deep gaps, if there are few of them, can be filled with thin wooden plates smeared with glue from all sides. After the material is dried, the top is trimmed flush with the floor surface.

- Large multiple cracks and holes to fill individually impractical. It is better to replace it completely.

Technology do-it-yourselfers

Parquet can be scraped manually or using mechanical means.

Manual shredding

The manual cycle must be conducted along the wood fibers with a slight pressure in the direction of movement at an angle of 45 degrees. To spend less effort, wood is moistened in advance, and the tool is periodically sharpened. The main advantage of the method is that it is dust-free.

Machine process

Technologies have changed significantly, and now home restoration of floors is a less labor-intensive, fast, and high-quality process. With the help of technical means restoration is carried out independently. You need to start looping only after the machine has gained momentum. If you lower the device to the floor earlier, you get a dent.

Rough scraping is completed if the surface has acquired a characteristic woody shade.

Stages of work

First scraping. The main task is to level the parquet and remove the layer of old varnish. This step is referred to as “coarse sanding,” because the process removes the largest tree layer to remove irregularities and grime. As a result, the parquet floor becomes brighter. Experts recommend intensive processing. up to 5 mm deep. The emery element for rough cleaning is coarsely abrasive (P40).

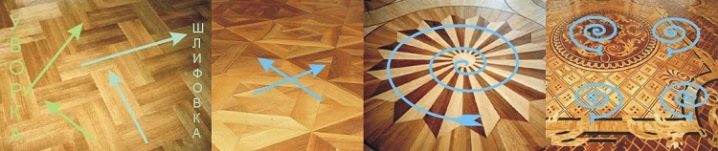

As a rule, the first sanding is carried out diagonally, using a drum-type machine or a surface grinding machine.

When patterned parquet has its own processing features:

- Herringbone, the direction of movement is diagonal.

- "Braided" and "palace", chiseling is done crosswise.

- “Artistic typesetting”, spiral movement from the center of the room.

During the work with car it is necessary to make the smooth movements with constant speed. If the worker stops or lingers in one place, a recess will appear.

The second chiseling or grinding is carried out after the garbage collection, which was formed during the implementation of the previous stage. Places that are difficult to reach with a scraper apparatus, and the corners in the room are processed by a manual cycle or with the help of special “boot” type machines.At home, you can use the grinder with a grinding nozzle.

The third scraping brings the grinding process to a logical end, eliminating the drawbacks that a conventional grinding machine could not cope with. It is carried out in the perpendicular direction to the movement of the cycling apparatus in the first stage.

At the stage of repair process the gap spackling pastes. To eliminate chipping and cracking, the selection of correctional compositions, individual for each individual case, is carried out, taking into account the structure and color of the wood. Proceed to the next stage should be only after the complete drying of the putty. In addition to ready-made formulations, a paste prepared from wood dust formed during scraping and PVA glue is used.

Finishing scrubbing is designed to make parquet smooth, update the surface. For what the surface grinding machine removes a thin top layer to remove excess paste. The operation is performed only along the parquet plates.

Final stage

After scraping, sweep up large debris and vacuum out small ones with a vacuum cleaner. As a protection, the parquet is covered with an antiseptic or fire-protective agent.

To give the refurbished surface a perfect look, it is pre-tinted or painted. It is easy to paint the parquet correctly, but it is better to get acquainted with the recommendations of the experts in advance.

After tinting, the surface is primed in two layers and polished with fine sandpaper. The primer will correct the remaining flaws. After that, experts recommend doing a technological break of 2-3 days, which will allow the surface to dry completely and polymerize.

Varnishing - the final stage

When choosing a varnish, you should focus on the functional specifics of the room and the type of wood. It is recommended to apply it from the lighted place. Coating the parquet with varnish in several layers will significantly increase the service life. To ensure good adhesion between the layers, each of them should be ground.

Coatings are classified as follows:

- With reversible films (drying). The class includes bituminous, nitrocellulose and shellac varnishes. Bitumen or “asphalt” compounds are based on natural or oil bitumens, as they are highly resistant to moisture.True, it should be noted their rapid thickening. Nitrolak is produced from cellulose nitrate. They dry quickly, but have low water resistance.

- With a protective irreversible hardening film. The group includes alkyd, melalinoalkidnye, epoxy, polyurethane varnishes.

It is recommended to apply varnish on the parquet with a brush, moving along the wood fibers. For the first layer, the composition should be liquid to ensure good absorption.

Flooring parquet

You can complete the restoration of the flooring is not varnishing, and rubbing parquet special mastic. Ready-made compounds are sold in hardware stores. On the packaging, manufacturers indicate the composition, method of application and material consumption. When rubbing parquet floors should consider wood species. Birch and beech dies swell from moisture, so water-based mastics are contraindicated for them, preferably on turpentine.

Often use solutions with wax, which are diluted with boiling water before mixing. To apply the mixture on the parquet with a thin layer, use a brush or a wide flat brush. When the first layer dries, the floor is covered with mastic a second time.At the end of the procedure, the parquet is rubbed with a polishing brush or a special machine.

In addition to mastics, the modern market offers special mixtures that include natural resins or beeswax, as well as natural oils. They are remarkably suitable not only for protective purposes, but also for decorative purposes, since they penetrate well into the wood and outline its texture.

The parquet becomes more expressive, more interesting, at the same time it is protected from abrasion. For example, "UV oil" allows you to update the composition once every few years.

Mastic - material unreliable with a low degree of stability. She wears off in a short time, and the operation will have to be repeated again. Therefore, for protective purposes, it is better to use varnish.

Tips and reviews

The parquet floor should be restored at least once every five years. Before rubbing, wipe the floor with a wet rag, this will soften the wood. The treatment procedure is carried out under the condition of temperature. In the cold period, it is recommended to cycle through when the heating is on and the windows are closed.

When working with parquet, you should wear soft socks, because even very soft shoes harm the unprotected surface.When using a scraper, there should not be long clothes to avoid tightening their parts inside the machine. You can only scrub parquet in the respirator and behind closed doors. Work is accompanied by a large amount of dust, therefore It is recommended to prevent its spread to other rooms. and try to avoid penetration into the respiratory tract.

If it is possible to update the flooring without scrubbing, then you should use it.

When using the equipment at home, you should make sure in advance that the electrical wiring is able to withstand the additional load. Begin the treatment procedure should be from the center of the room. When moving, each next lane should find the previous one.

It should not be much pressure on the scraper machine, because it leaves dents that will be difficult to fix. Grinding is carried out along wood fibers so as not to disturb the structure. A drum machine is suitable for immaculate scraping of hardwood parquet. However, the treatment of soft wood with it may cause wavy surface defects.Therefore, the primary scraping in the second case is carried out by tape machines.

When using putty on wood it should be remembered that it is not combined with hardwood. Its use can cause stains after applying varnish on the floor surface. Before proceeding with varnishing parquet, lacquer must be kept at room temperature. The difference between light and dark plates makes the parquet more bright and interesting, but if you want to make the color more even, then you need to either tint it or disguise it with a matt varnish.

Alkyd varnish dries quickly, its service life is 10 years. Parquet covered with epoxy varnish will last up to 30 years, but the coating dries within a week and is toxic. The safest is an acrylic version, it provides a service life of up to 50 years. However, it is very expensive and has the ability to fade in the sun.

If you plan to also glue the wallpaper, then the work on the treatment of the floor is best done before. In fact, it all depends on the professional level of the specialist and the modern technology. If an experienced person makes a scraping, moreover using modern high-tech equipment,equipped with dust collectors, the restoration of the parquet will not greatly affect the environment.

At home, when scraping with your own hands, you can get a lot of dust and dirt, which will settle on the renovated walls. As you know, not all types of wallpaper are easy to clean.

In order to extend the life of the parquet you need to follow the following rules:

- Set the optimum level of humidity in the room.

- Eliminate large abrasive dirt in the form of sand and rubble, which is brought from the street. To do this, just lay in front of the mat.

- Ultrafillet protection.

- Installation of felt or rubber soft plugs on furniture legs.

- Regular manual wet cleaning.

- Periodic treatment with special means - polish, wax or oil.

How to loop the flooring, see the next video.