Features of the choice of cable for underfloor heating

Everyone who decides to do electric heating in a house will one day be asked a lot of questions, one of which is related to the specifics of the choice of cable for a heated floor.

Special features

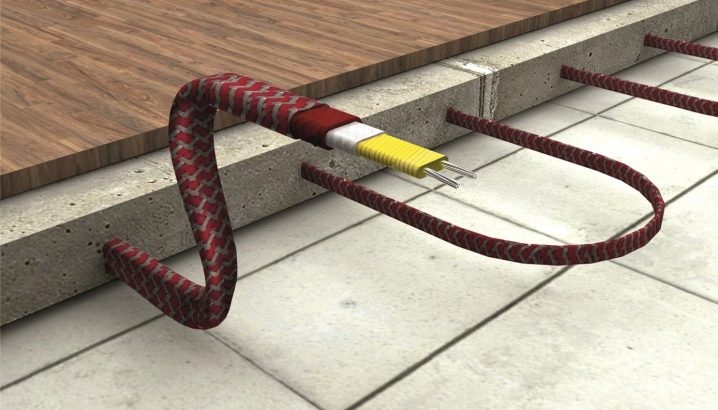

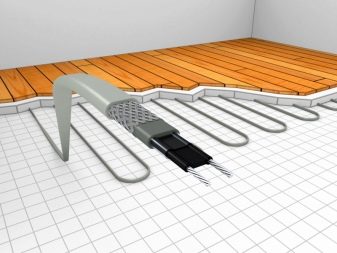

Electric floor heating is a modern type of residential heating system. This structure consists of heating mats laid under the floor or between layers of concrete screed and special regulators.

The advantages of the scheme include:

- uniform distribution of heat across the height of the building;

- the absence of circulatory disturbances in the form of convection currents - the movement of heat in the air;

- simplicity and clarity of self-installation of the system;

- budgeting professional installation;

- saving of useful space of heated space;

- no need for additional equipment;

- possibility of installation under any floor covering;

- increased comfort and convenience;

- environmental friendliness;

- possibility of use by people suffering from various types of allergies, bronchial asthma.

The disadvantages of electric heating are:

- high cost of 1 kW of electricity;

- the creation of an electromagnetic field within a heated room;

- mandatory skills in handling temperature regulators;

- the complexity of diagnosing and repairing the system;

- the existence of restrictions on heated buildings in height;

- the need to improve electrical safety by grounding.

However, with rational drafting and proper installation, all these shortcomings are eliminated by themselves, so this system is becoming increasingly popular among consumers.

The main active element of the electric floor heating is a heating cable. The effectiveness of the functioning of the entire heating mechanism depends on its quality and characteristics; therefore, the heating cable for this purpose should be chosen carefully and responsibly.

Kinds

Before you make the final choice, you need to familiarize yourself with all types of heating cable. There are the following types.

Resistive cable

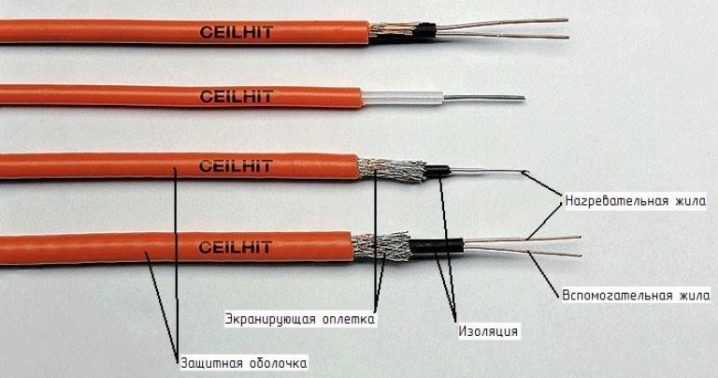

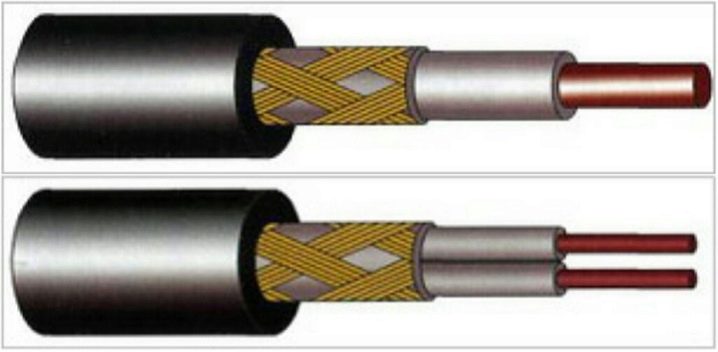

It creates the same temperature along its length and is divided into types:

- Single core This species lives up to its name. It consists of one heating core, reinforced with a sheath of wire or foil. The process of connecting such a cable requires the convergence of both its ends in one place, that is, their connection to the temperature regulator. Single-core cable has several advantages, namely:

- maximum heating temperature;

- low energy consumption;

- affordable price.

- Two-core. It consists, respectively, of two veins, which are also surrounded by a protective film. For connection to a strong cable no return is required. The circuit is closed by connecting a special coupling to the free end of the wire. Its benefits include:

- easy installation;

- the possibility of forming a route of any shape and length;

- one-way connection;

- immutability of the electromagnetic field.

Self regulating

The basis of this cable are two conductive wires in contact with the polymer matrix of the semiconductor, which regulates the heating system, depending on the temperature of the surrounding space. The matrix is isolated in two layers and protected by a screen braid located between the layers. The advantages of a self-regulating wire are as follows:

- universality;

- durability;

- the ability to independently select the temperature in the room;

- damage resistance;

- reliability.

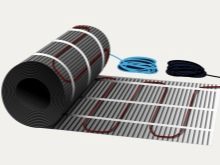

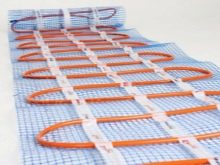

Electric mats

To make installation of a heated floor more simple and convenient, and also to reduce financial expenses to a minimum, it is recommended to use special heating electric mats. In turn, they are divided into:

- cable;

- carbon;

- film.

Let's take a closer look at each view:

- Cable (wired) mat - it is a flat flexible device consisting of a single-core wire attached to a metal grid in the shape of a snake. These mats are ideal for tile and tile finishes.

- Carbon or carbon fiber mat is a structure of parallel-mounted autonomous self-regulating heating rods,emit infrared radiation, which is the source of heat in such schemes.

- Film mat, in fact, is arranged in the same way as carbon.

The only difference is that the carbon rods are additionally protected by a polymer film.

Specifications

Regardless of the type of heating cables are characterized by a number of key indicators:

- Core material. In terms of their composition, the wires are divided into:

- aluminum (more suitable for stationary installations);

- copper (flexible but heavy);

- alumo-copper (the most convenient and economical option).

It should be remembered that the cable material depends on its resistance.

- The number and thickness of wires in the vein. This indicator is directly proportional to the flexibility of the wire, that is, the more thin wires, the more elastic the cable.

- Insulation material. In order to protect the cable's fiber from mechanical damage, as well as leakage prevention, all wires are strengthened and divided according to the type of insulation into:

- armored;

- heat resistant;

- waterproof;

- protected from pressure and so on.

- Operating temperature range (heat resistance). The higher this figure, the greater the heating temperature of the cable without losing its original properties.

- Section or area of the current-carrying core. For single-core wires, the cross section is determined by the formula for the area of a circle (the product of the square of the radius and the number Pi - 3.14). For two-core cables, the section is the sum of the areas of the cuts of both veins. According to the "Rules for the Installation of Electrical Installations", the size of the cross section is selected taking into account the planned loads (such as current power, for example) using special tables or averaged values.

- Life time. On average, it ranges from 20-25 years. After examining the basic characteristics of electric cables, we can conclude that for a warm floor you should choose copper or aluminum-copper heat-resistant wires with a cross section of at least 1.5-2.5 mm2, allowing you to turn on the thermostat at the maximum heating temperature.

Installation

Laying the electric floor is carried out according to the following algorithm:

- Drafting and calculating areas. First you need to draw a plan for each room in which the planned installation of the heating system. After that, a separate calculation of the total area of the room (Sot) is performed.Further on the plan marks the placement of furniture, calculated the area occupied by it (Sm). On the basis of these data, it is possible to calculate the direct stacking area (Sу) using a simple formula: Su = Sobs - Sm

Heated surface should occupy from 50 to 80% of the total area of the room, otherwise the use of heated floors is impractical.

- Calculation of heating power. At the preliminary stages of installation, it is necessary to calculate the power of the electric heater. For this there is a formula: Ртр = Рп * 1,3, where Рп is the power of heat loss, Ртр is the power of thermostat. That is, the power of the heating device should be calculated with a margin of 30%.

- Selection of resistive cable or heating mat. Wires are selected based on the power and type of space. This can be done using special assortment tables, which are produced by various manufacturers. The choice of mat is also carried out on the basis of indicators of power and range.

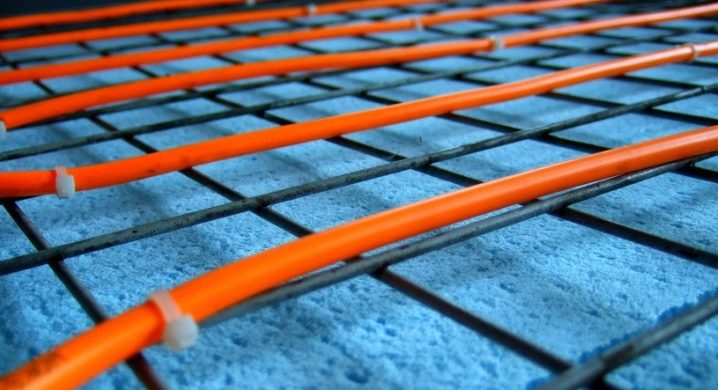

- The calculation of the required amount of heating element. For the cable floor, the laying step, that is, the distance between the wire circuits, is determined. Calculations are made according to the formula: x = Su * 100 / Dkabwhere Su - cable laying area, Dkab - wire length.

To calculate the last variable, that is, the cable length, it is better to use the built-in calculators on construction sites. In determining the required number of heating mats formulas are not needed. Enough to know the paving area.

- Calculation of the electrical system of a heated floor. It is better to entrust this stage, which includes the collection of technical and permits documentation for installation, as well as the assessment of the state of electrical wiring, to professionals.

- The choice of thermostat. Going to the store for the most important device in this scheme, it is advisable to follow simple recommendations:

- listen to the advice of consultants;

- take into account current load indicators;

- give preference to models with a temperature sensor if the floor heating system is planned to be used only as an additional source of heat;

- acquire a multiplex controller with remote sensors, if the electric heating will be carried out simultaneously in several rooms.

- Electrical wiring design. With a view of safety and the further uninterrupted functioning of system it is betterentrust this work to an electrician.

- Thermal insulation subfloor, for example, mineral wool.

- Cable fixation or laying mat. The process is not particularly difficult.

- Installation of thermostat and sensors. This step is the most crucial of all. If you are not confident in your abilities, then entrust the work to a professional.

- System connection A single-core cable is connected by connecting two ends to the device, and a two-core cable is connected to one end. To close such a circuit, an end clutch is used, with which the free end must be connected. At this stage, it's time to cut, shorten or lengthen the cable, adjusting it to the desired size.

You can cut the cable yourself using suitable tools.

- System check. Held within half an hour.

- Fill. If tile is selected as a floor covering, the concrete screed can be replaced with tile adhesive.

- Alignment. The principle of operation is in the distribution of the solution.

- Drying. The layer of the filled mixture should dry out. To speed up the process it is recommended to open the door to the street.

- Laying finish decorative coating. It remains only to lay the material chosen as the floor covering.

How to repair?

If the electric floor heating system has ceased to function, it is necessary to find the cause of the malfunction. As a rule, there are three of them:

- lack of power supply;

- failure of the thermostat;

- cable breakage or damage.

For diagnostics, you need a screwdriver indicator or a multimeter. With the help of these devices, the presence of voltage phases is determined, the resistance fluctuations are measured, and the cable breaks are detected. If there is no power supply, contact a specialist. It is recommended to replace the regulator in case of breakage. If the wire is broken, it can be repaired by yourself. The technology for repairing a broken cable is as follows:

- de-energize the system;

- remove flooring;

- dismantle the concrete screed on the damaged area;

- find a cliff;

- clean the ends of dangling veins;

- to connect them with sleeves with the help of press-ticks (you can also solder);

- isolate the joint with a shrink sleeve and pour concrete;

- check the operation of the system;

- restore the screed and topcoat.

Manufacturers

A list was compiled representing the top 5 popular brands of a warm electric floor:

- Danish firm leads Devi. The high quality of its products is not the only advantage. The company is pleased with its affordable price, ease of service and durability of the systems. Product reviews are completely positive. Consumers have not recorded a single case of failure of the structure due to marriage.

- Korean stamp Caeo produces infrared film mats. Its products are much more expensive, but have impressive technical characteristics.

- Leading domestic manufacturers are competing companies. "Heatlux" and "National Comfort", producing high quality heating systems.

- Firm Ensto (Finland) pIt represents a product on the market that is the best fit for the Russian climate. Systems are designed specifically for use in places with adverse conditions: for rooms with high humidity, for excessively dry, unheated, having other problems.

- Company Topan specializes in the production of reliable and low-cost cables, the most famous of which is TOP-3UTP10PR-GY.

Successful examples and options

The floor, which maintains a comfortable temperature for the feet, is the epitome of a modern concept of home comfort. Today it is not necessary for the floor to act as a gray background.

Unusual and stylish flooring can be used as an accent.

Fans of the classic conservative style can also find their own options. Wherever you install a heated electric floor system: in the kitchen, bathroom or nursery, this room will become your favorite place in the house.

You can find out how to choose the length of the heating cable in the next video.