Repair of electric floor heating: causes of malfunction and features of repair

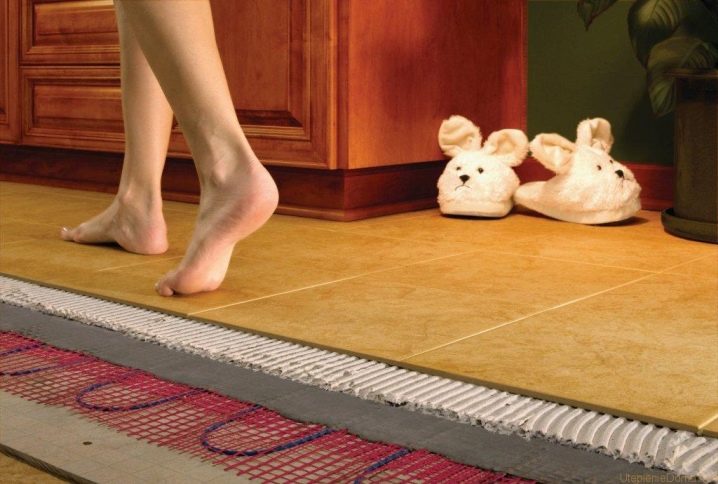

Heated floor is not only a source of additional heating, but most often the only one, especially when it comes to a cottage or a country house. Since this is a closed type of space heating, in which the heating elements are hidden from prying eyes, it is difficult to understand in time for what reason the floor is not warm enough. Malfunctions of a heated floor and their elimination depend on the type of heating system and are often associated not only with damage to the heating element, but also with a disruption in the supply of electricity or water.

Malfunctions of a water heated floor

Water heated floors - pipes laid under a concrete floor screed and connected to a centralized or autonomous water distribution. The water floor system consists of pipes through which hot water flows (metal, copper, plastic, polypropylene and others),mixing units that maintain the desired floor temperature, and distribution manifolds, accelerating warm water throughout the system.

There may be several reasons why the heated floor is not heated, and, as a rule, it is clogged filters, pump malfunction and system installation errors. Fault diagnosis is carried out with a fully enabled system by probing. If the floor heats up badly in any one place or one room, then the coil or distribution units, the collector of this particular room, is most likely to be defective.

If heating does not occur throughout the house, then the problem may lie in the filter, the pump, the boiler itself and even a small amount of water in the distribution tank. In order to accurately establish the place where to make the opening of the screed, you must have a plan with the exact location of all nodes and elements of the heating system, which you will be given after the installation of the floors.

First check the amount of water in the system. To do this, the fluid is poured into the expansion tank until it begins to flow out of the drainage pipe. As practice shows, 20% of cases of problems of work of warm floors are connected with this reason.

If heating does not occur only in one room, then the water filter standing in the distribution system of this particular room is checked. Unscrew and clean the cartridge. Often it can detect particles of rust that clog the "sieve." The presence of scale on the filter is not uncommon, especially in regions with hard water.

In this case, the filter is placed in boiling water with citric acid and "cooked" until the scale dissolves.

If there is enough water and the filters are clean, but the water pressure is low, then need to pump the system. Due to the small diameter of the coil (5-10 mm), any incorrect bending of the pipe can lead to the formation of an airlock. To bleed the system, it is necessary to open the air valve and wait until the water completely squeezes the air out of the expansion tank. The fact that the air is completely out is evidenced by the water flowing from the air valve.

After that, the valve is closed, and the system is completely filled with water until it begins to flow from the drainage tube. If the pumping did not work, then most likely the pipe coil is clogged somewhere.

After the air has been removed from the system, it is necessary to listen to the operation of the circulation pump.If during its work extraneous noises are heard (the pump should work smoothly, without knocks and drops, vibrations), then it is better to carry the pump to the diagnosis. It will also be useful to check the pressure in the system using a pressure gauge installed after the pump, which normally should be 8 pascals or 0.5 atmospheres. Low pressure may indicate a leak in the pipes.

To find a leak, you need to completely fill the system with water (after pumping), and leave the pump to work for two hours. If the water does not start to flow out of the drainage, then the entire system and its individual elements are crimped. To repair a leak, you will need to open the area above the damaged pipe.

If the water used for the water heating system is not properly filtered, then the result of the work is the formation of clay plugs in the pipes, which can only be removed by specialists using properly selected reagents.

Malfunctions of an electric heat-insulated floor

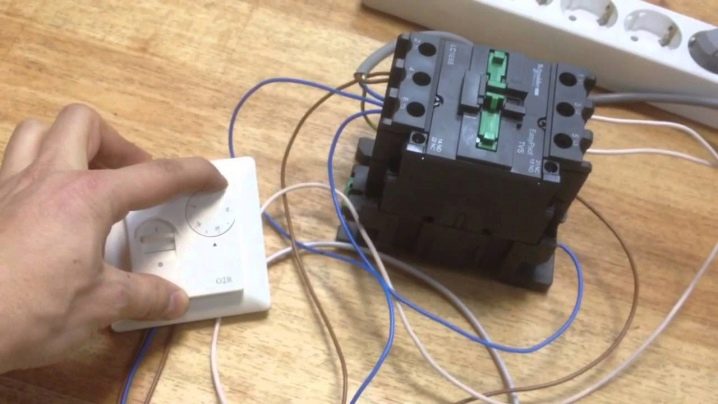

Electric underfloor heating of any type of heating element has one common design - the heating element itself, the presence of a thermal imager and a mandatory temperature sensor.The floor starts to warm up under the action of the current, the temperature sensor monitors the moment when the floor equals the set temperature or air temperature in the room, and the thermostat turns off the system when it reaches this value and turns it on when the floor cools down.

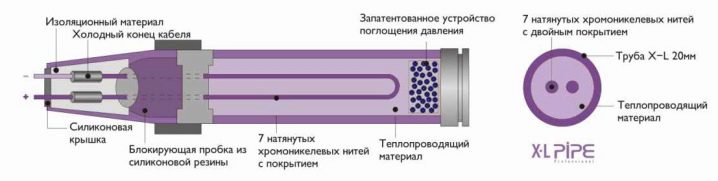

Liquid electric floors are heated by a special fluid in the pipes, but they are heated with the help of electricity through chrome-nickel threads. A floor of this type does not need a pump and connection to the house water supply system.

An important feature of the electric floor heating is its autonomy in each room. If the floor is not heated in the same room, then the fault must be sought in the system of this room. A popular list of faults includes a wire break, a heater rupture, a sensor or a regulator malfunction, a short circuit due to the charring of contacts or a break in the insulation.

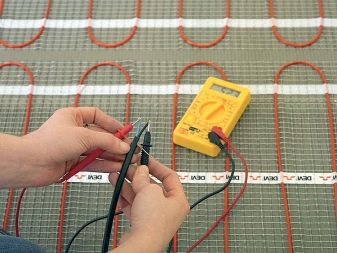

Fault diagnosis should start with a floor sensor and control system. If you do not have basic knowledge in electrical engineering, then it is better to call a specialist so as not to put yourself at risk.

The voltmeter measures the system voltage at the terminals of the power wires in a room with a non-working floor, and then it is compared with the voltage at the same terminals in the sockets of other rooms.If the voltage drops by 10 units, then the contact between the wires and terminals is of poor quality. The fault is eliminated by stripping the ends of the wire after removing them from the terminals (with a completely de-energized house).

If, after stripping and securing the wires with screws, the voltage does not level, then the problem is in the general wiring system.

You can also check the operation of the thermostat by measuring the voltage at the terminals. When the temperature controller is off, the voltage should be zero, and when it is turned on for maximum power no less than 210 volts. If the voltage is lower, then the regulator is faulty, or the heating element is broken.

Looking into the passport of the thermostat, you can find out the value of the amperage, which you need to measure with the help of thermometers. If the current strength does not match the set, then the regulator must be repaired in a service center. If there is no current at all, then there is most likely a wire breakage that is suitable for the heating element. If the current strength is higher than the stated one, then, most likely, a closure has occurred, the cause of which is most often the high humidity of the floor and insufficient drying of the screed before layingheating elements.

It is possible to calculate the circuit by the smell of burnt insulation or by how weakly it hits the current through the floor.

Malfunction of infrared warm floor

Infrared warm floor - the thinnest film with a heating element, which is sold in rolls and can be used under any floor covering. In this case, it is not the air of the room that is heated, but the objects that are in it. This type of floor does not dry the air, is easy to install, connects and can be moved to any place.

Due to the fact that the conductive graphite elements are connected in a parallel way and are located in their own conductive path, failure of one element does not cause damage to the entire system. However, the failure of several tracks at once can significantly reduce the quality of heating. If the efficiency of the floor is significantly reduced, it is necessary to check the strength of the current in the regulator. A 10% reduction in current means that too many heating elements have failed.

Repair heating elements of this type are not subject. The only thing that can be done in the event of a breakdown is to increase the heating temperature or to completely replace the tape.

How to prevent breakage?

First of all, do not lay the electric floor heating in places where there will be massive furniture. It's not about the weight of the furniture, but about the area in which it comes into contact with the floor. The larger this area, the greater the risk of overheating of the system in this place.

In order not to damage the heating element, the screed must be thoroughly cleaned of debris. The load on the floor can lead to failure of the heating element if it is in close contact with a pebble or other foreign object.

Do not walk on the floor in the shoes at the time of laying elements, so as not to damage their integrity.

If you are not a professional installer, do not buy cables or films more than required, take a clear size. When fitting heating elements by cutting off unnecessary, they are easy to disable, breaking the insulation. This is one of the frequent causes of the rapid failure of the electric floor heating system.

For information on how to repair an electrical floor and prevent errors, see the following video.