Soundproofing the floor in the apartment: design features

The modern world is filled with various sounds and noises, which negatively affects the psychological health of people.

For many city dwellers, an apartment is a refuge from the outside world, so it is important to isolate it from sound stimuli. First of all, it is necessary to do high-quality sound insulation of the floor.

Special features

Effective soundproofing of the room can be achieved only when the neighbors above also make noise insulation of the floor. This way you can maximally protect your home from the most common and annoying shock noise.

Sound insulation floor system is expensive, than isolation from extraneous noise of walls or ceilings. It is floor coverings that are most often exposed to external influences that form percussion or airborne noise.It is therefore very important to make high-quality sound insulation under the screed, since this method is the most effective in the fight against sound stimuli.

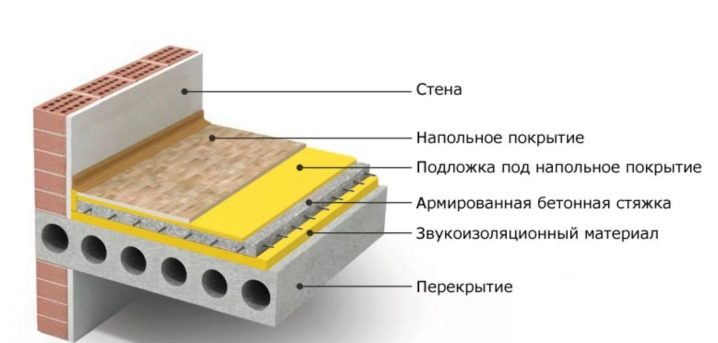

The peculiarity of the sound insulation of the floor construction is that it is not enough just one sound-proof material. You must use a set of elements that will provide full protection.

Very much depends on the type of flooring.

For example, wooden floors need improved sound insulation, since wood resonates strongly and transmits sound waves.

Soundproofing floor systems has its pros and cons.

Among the benefits can be identified insulating effect and ensuring peace and tranquility.

The disadvantages can arise if low-quality material was chosen for sound insulation or if the floor insulation works were performed with violations.

Types of screeds

Soundproofing under the screed provides for the preliminary preparation of the base. All joints and cracks are smeared, including, and holes for communication. After the surface is cleaned, you can go to the screed.

Types of screeds:

- Dry or composite screed - involves the laying of gypsum fiber tongue and groove sheets on top of a layer of expanded clay. The technology of the screed is quite simple - clay is poured on the rough floor, sand is added to it, then the gypsum plasterboard is closed. The dry screed device takes very little time and does not require thorough cleaning after completion of work.

- Wet screed - is a concrete fill with a thickness of 4.5-5 cm. It is poured on an empty base or on top of the sound and waterproofing layer. The disadvantage of this type of screed is a long time, which is necessary for the complete drying of the concrete. On average, it takes 12 days.

- Semi-dry screed - technology, similar to the wet screed, but takes less time until the floor is fully ready for the final finish. Instead of a concrete solution for a semi-dry screed, a cement mixture with the addition of water and fiberglass is used.

Materials

The construction market has a huge range of materials designed to improve the acoustic characteristics of the space and provide high sound insulation of the floor. Among sound absorbing materials The most popular are: mineral wool, chamotte, polystyrene foam, penofol, isofon and foam glass.

- Extruded polystyrene was originally used for thermal insulation of various designs. But recent studies have found that it absorbs shock noise well.

In order for the insulation to absorb sounds, its thickness should be 2-4 cm.

- One Of the most effective materials for sound insulation is mineral wool. Its characteristics depend on the density and type of material. For example, stone wool is able to withstand high temperatures and delay sound waves, and glass wool has good sound insulation performance, but requires increased accuracy when installing it.

- Good results can be achieved with the use of foam glass.. This material is resistant to burning, does not emit toxic substances and is able to become a reliable barrier to extraneous noise. Working with foam glass is easy, so even a novice in the construction business will be able to cope with the task.

- Often for sound insulation floor systems use substrates. Cork underlays are most common.made from crushed compressed cork bark. They have high sound insulation properties and can not only muffle the noise inside the apartment, but also isolate the neighbors from talking and trampling from the bottom.

If we talk about manufacturers, the company Tekhnonikol, which manufactures various sound insulators, enjoys special confidence. Among the manufactured products, “Isofon”, “Technolight” and “Tekhnoelast-acoustics” are the most prominent. These sound insulators not only absorb sound waves, they also retain moisture and resist mold.

Which is better?

Best of all with various noises copes floating concrete floor. In this case, the slab and the floor covering are not interconnected with the walls, the substrate helps to absorb extraneous sounds.

The level of noise absorption is estimated on a scale from 0 to 1. The greater the value, the better the material used for sound insulation. A zero factor means that the material does not delay the sound at all, and the unit coefficient indicates that the sound insulator perfectly keeps the noise.

Floating floor is considered the most effective sound absorption method.. Its design is not in contact with the carrier, so it does not participate in the propagation of noise. The disadvantages of a floating system include a lot of weight and a decrease in the height of the space.

The choice of a good heat and sound insulation material contributes to better protection of the flooring from noise and cold.Most often for this purpose use a dry coupler, which is characterized by ease and speed of application.

Well with the task of sound absorption copes double protective layer. The system consists of backfill, on which two layers of GWP are laid. The second layer is laid with a slight shift so that the seams do not coincide. The thickness of the structure is about 4 cm, so the room does not lose its height.

The precast floor, which is the laying of the finishing coating on a thin sound-insulating layer, is very popular.

A polymer substrate is used as a sound-absorbing material. Close construction can laminate flooring or MDF-plate.

Installation of soundproof material

Properly make sound insulation of the floor construction in the apartment with your own hands, if you first get acquainted with the properties of sound-absorbing materials and technologies for their installation.

The best way to protect the home from shock and airborne noise is a floating floor. For his device will need to perform cement-sand screed in such a way that it does not come into contact with the walls and the base.To do this, you must use vibration-isolating materials that can absorb sound vibrations. Such materials include basalt and glass wool.

The main stages of laying noise insulation:

- First you need to level the base, cover up the gaps and cracks.

- It is necessary to lay sound-absorbing material on the basis, well sizing joints. If mineral wool is used for work, careful sizing will improve its thermal insulation properties.

- Further along the entire perimeter of the walls it is necessary to lay a layer of separating material. It should be located above the level of the screed.

- Excess material is neatly cut.

- Now you need to lay a layer of glass wool or mineral wool on the base. Available pipes in the room need to be wrapped in soundproof material.

- Above the mineral wool, it is necessary to fix a layer of plastic film that will protect the material from ingress of cement mortar.

- Next you need to install the lighthouses and fill them with cement-sand composition.

- After the solution dries, it is necessary to proceed to the installation of the topcoat. At the same time, there should be gaps near the wall, which can later be closed with plinths.

For details on the process of making the floor for a floating floor, see the following video.

Often the source of noise are wooden floor structures. Therefore, it is very important to make high-quality sound insulation for them. The floating system may also perform such a task, but it will look a little different.

To prevent wooden structures from transmitting sound waves, they should not touch each other.

To achieve the desired result, sound-absorbing material must be placed between the lags and floor beams. Lags to the beams do not need to be fixed, since they must lie freely on the ground.

The material must also be in free space. A layer of another soundproofing material, such as foam glass or stone wool, must be laid on top of the log.

Then you need to make the flooring of OSB-plates and fix them with screws. In this case, the flooring should not be adjacent to the walls. To achieve this, you need to lay foam glass along the walls or any other material. At the end of the work, it will be necessary only to install the baseboard and lay the laminate or linoleum on the finished surface.

Professional Tips

There are several tips to make it easier to soundproof the floor:

- For example, a vibration-proof sealant can be used to close the gap between the wall and the floor covering.

- It is best to fix the plinth to one of the coatings. Otherwise, the vibrations that occur in one design, will move to another, and this will violate the technology.

- If wires, pipes or corrugations pass under the floor covering, before starting all work they should be covered with insulating material.

- Replace the foam soundproof strip can be rubber backing or a piece of roll tube. The main thing is that all the joints should fit snugly together.