Sound insulation plaster: types and scope of application

One of the easiest and most effective ways to reduce the level of noise in a room is to use soundproof plaster. This material is actively used not only in office, administrative and public buildings, but also in residential premises. Types, features, advantages and disadvantages of soundproof plaster consider in this article.

Special features

In the modern construction market there are many different finishing materials, which have sound-proofing characteristics. One of these coatings is a special type of plaster. A high-quality material, when properly applied, can absorb up to fifty percent of the noise that occurs outside the room.

Unlike many types of noise insulation coatings, the plastered surface is more uniform and has no joints, which ensures a high level of sound absorption. When carrying out finishing works, it is worth remembering that it is not recommended to apply high-density paintwork materials to the plaster, and also to glue the walls with wallpaper, otherwise the insulation will be low. Glue and thick paint clog pores on the surface, which degrades the properties of the plaster to absorb noise.

Advantages and disadvantages

Like all types of sound insulation coatings, plaster has its pros and cons. Consider the advantages of this material:

- Affordable cost.

- Before applying the mixture the walls do not need careful preparation and leveling.

- Ease of application. Even a beginner can cope with such a task. It is only important to follow the basic guidelines for finishing.

- Safety coverage for human health.

- Rodents and insects will not be able to destroy or spoil such a coating.

- High vapor permeability.

- Resistance to temperature and moisture. Thanks to these qualities, the plaster can be used in rooms with high humidity.

- Durable and durable coating.Properly applied quality material can last more than ten years without changing its technical characteristics.

The disadvantage of the soundproofing mixture is the need for additional decoration of the walls with decorative materials, which increases the financial and time costs of finishing work.

Species

The differences of all sound insulation mixtures are in the composition of the material. Such plaster consists of:

- bases, which may be a cement mortar, lime or gypsum;

- polymers;

- various fillers.

Fillers are small granules of no more than five millimeters in size. The following components can be used as additives:

- porous clay;

- mineral vermiculite;

- pumycite

The quality of the plaster and its sound insulation characteristics will depend on the composition of the mixture. Sometimes a material such as aluminum powder is used to make a material. This component provides the coating with high porosity, which has a good effect on the absorption properties of sounds.

Application area

Plaster mixes with properties of sound insulation are often used in rooms with high traffic of people.In places of public catering, for example, in cafes and restaurants, it is necessary to ensure a good level of noise insulation for comfortable rest of visitors. In addition, often these places are located on busy streets or near the roadway.

Such plaster is often used in cinemas, protecting the halls from unwanted noise, which can interfere when watching a movie. Also, this material is widely used for finishing the following buildings:

- office rooms;

- conference rooms;

- business centers;

- libraries and reading rooms;

- manufacturing enterprises;

- administrative buildings;

- courthouse;

- Living spaces.

For decoration of residential premises most often used gypsum soundproofing plaster. This material creates a completely aesthetic coating that does not necessarily cover the final decorative layer. To create a high-quality sound-absorbing coating, plaster mixture must be applied around the perimeter of the room. To effectively protect the room from extraneous noise, it will suffice to form a layer of the mixture with a thickness of two and a half centimeters.

Popular manufacturers

So that when using sound-absorbing plaster the results of the finishing exceed all expectations, it is important to choose a quality mixture. Before buying it is recommended to get acquainted with the most popular manufacturers and reviews of their products.

"PL groups"

The company "PL Group" produces popular building mixes under the brand Paladium. The company's products are not inferior in quality to imported counterparts. Dry mixes are produced using modern high-tech equipment from high-quality domestic and imported components.

Soundproofing plaster Paladium is made on the basis of foam glass. In addition to the functions of noise insulation, the mixture has insulating properties. The solution is environmentally friendly and flame retardant. Plaster is suitable for both external and internal work. The mixture creates a durable and reliable coating that will last more than ten years without losing the original properties.

Reviews of this product are mostly positive. Buyers note the following advantages of the composition:

- convenience in application, the mixture is put in the same way as any other leveling plaster;

- material resistant to mold and mildew;

- good resistance to moisture and temperature extremes.

Some consumers note that if the plaster is not applied correctly, the coating will not have good thermal and sound insulation characteristics.

Ivsil

Ivsil manufactures high-quality building materials using the most advanced technologies. At the same time, prices for the company's products are quite affordable. Ivsil dry construction mixtures are used both in industrial construction and for the decoration of residential premises. Ivsil soundproofing plaster is made on the basis of cement, special fillers and polymers. The composition of this material was developed by the company itself and is absolutely unique. The mixture also has excellent thermal insulation properties. The composition of the plaster does not contain flammable substances, which makes the material fireproof.

The total thickness of the applied layers of the solution can be from ten to fifty millimeters. The material does not crack even when applied in a thick layer. Since Ivsil soundproofing plaster belongs to the class of light mixes, this material is suitable for applying on the facades of old buildings, because it does not create a large load on the walls.

"Favorite"

Firm "Favorit" is a major Russian manufacturer of finishing materials. Dry mixes of the company are manufactured under the De Luxe brand. On the basis of the company operates a research laboratory for the development of its own unique compositions and testing of finished products.

De Lux soundproofing mixtures are designed for internal and external works. Stucco has high technical characteristics and low cost. The material is resistant to moisture, so it can be used in bathrooms and in the kitchen.

Soundproofing plaster is made on the basis of high-quality cement with the addition of special fillers, sand mixture and cellular glass. The finished solution is characterized by economical consumption.

The dry mix is available in twelve kilograms. The finished solution can be applied in layers from five to forty millimeters thick. The coating can be operated within the temperature range from minus fifty to plus fifty degrees Celsius.

Knauf

Knauf is a world famous manufacturer of building materials.The company primarily owes its popularity to the high quality of all manufactured goods.

Knauf AkustikPutz soundproof dry mix is made on a plaster base with the addition of mineral components. The size of fractions in plaster ranges from three to five millimeters. The material is absolutely safe for health, as it does not include toxic components.

The finished solution is simply distributed over the surface and creates a high-strength coating. The mixture has excellent adhesion to most types of materials. The total thickness of the applied layers should be more than fifteen millimeters.

How to apply?

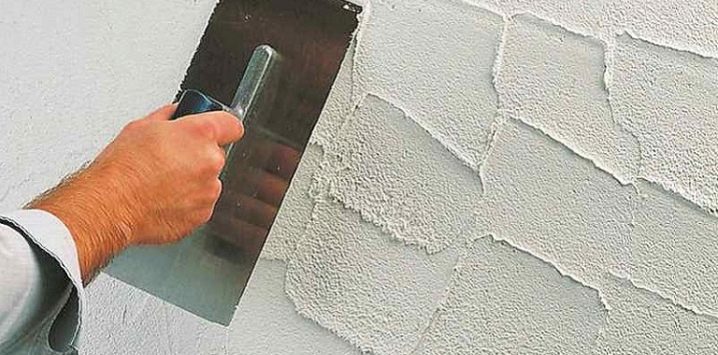

The process of applying sound insulation plaster is no less important than the quality of the material itself. Due to non-compliance of the finishing technology, the obtained coating will not meet the declared characteristics and will not provide an adequate level of noise insulation. Plaster mix is suitable for application on concrete, wooden and brick walls. It is possible to apply sound-proof solution in the manual or machine way.

Foundation preparation

Soundproof plaster does not require perfectly smooth walls for application.However, some preparatory work still needs to be done. The surface is cleaned from the old coating, dirt and grease. Strong irregularities are recommended to be eliminated. If there are cracks on the base, they should be sealed with cement mortar.

For better adhesion, it is recommended to treat the surface with a primer of deep penetration. It is recommended to ground the walls in two layers. To improve the soundproofing characteristics of the coating, a grid of metal with cells of 1x1 centimeter is attached to the walls.

Preparation of the solution

Further preparatory and finishing work should be performed at air temperature in the range from +17 to +25 degrees and humidity not more than 65%. Instructions for breeding plaster will be listed on the packaging material. For most species, the process looks about the same:

- In a clean container with a volume of thirty liters or more pour dry mix.

- On one bag of dry plaster you need to take about twelve liters of water. The exact proportions are shown on the product packaging.

- With the introduction of water, the solution is constantly stirred. This procedure will take about seven minutes in total.The mixture should be viscous and homogeneous.

- The solution is left to stand for ten minutes, and then stirred again.

- The resulting mixture must be used within four hours.

Finishing work

Application of the solution produced in at least two layers. The total thickness of the coating should be approximately twenty millimeters. You can increase this figure to two and a half centimeters. Layers are applied successively after complete drying of the previous coating, no more than ten millimeters thick. Too thick a layer can crack when dry.

Plaster coating level aluminum rule. Excess mixtures can be removed with a plaster semi-plaster. After applying the mortar, the walls can be coated with water-based paints or decorative plaster mixtures.

In the next video you will find a presentation of heat and sound insulation plaster De Luxe TEPLOLUX.