Soundproofing ceiling in the apartment

Rare lucky ones do not face the problem of noisy neighbors above. They either live on the top floor, or have an apartment in a house with five-meter ceilings and thick walls, or they are just lucky and the neighbors live very quietly. The rest of us have to wonder from time to time what kind of furniture the neighbors are now moving, why they brought a horse in the apartment and why they need to play the violin on the weekend morning.

But the problem is solved. Noise insulation ceiling in the apartment will help create peace and comfort in the house.

Special features

Before throwing out saving earplugs, it is worth exploring the subtleties and features of the process of sound insulation.Its installation, although it does not require tremendous efforts, should be carried out after preparing and taking into account all possible nuances of the work.

The main advantage of noise insulation is that the extraneous noise from the upper floor will no longer interfere with a quiet life. The second obvious advantage is that the surface of the ceiling will turn out even and beautiful. At the same time you can do the work yourself. This technology is simple enough to equip soundproofing could a man who did not do it even once in my life. Also among the advantages worth noting that the work takes place with virtually no dust and dirt.

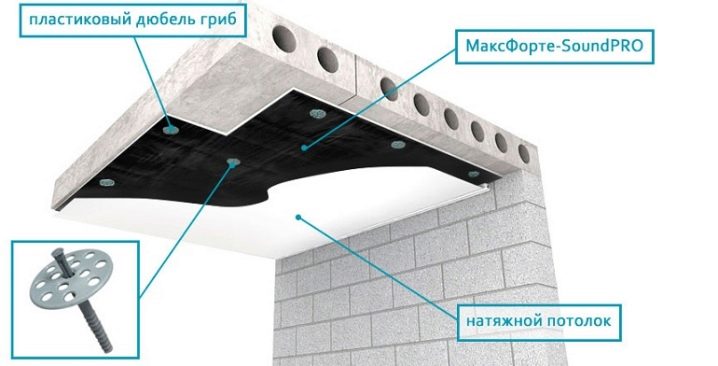

The main disadvantages of the use of soundproof materials are temporary and financial resources that need to be spent on installation work. In addition to the insulating material itself, you will need to install the batten and stretch ceiling, and this is already a significant amount and the need to hire specialists to install the stretch ceiling. If the beauty of the sheathing and sound insulation is of no interest to anyone and it can be made with your own hands, since this is a draft layer, then the stretched canvas of the ceiling is a decorative element. It should be mounted by professionals.

A serious disadvantage of sound insulation is that it “hides” exclusively in the system of stretch or hanging ceiling. If for apartments where its height is normal or average it will pass unnoticed, then in small apartments with a low ceiling an extra 10 cm of height that insulation will take is an unaffordable luxury.

If water gets from the apartment of the neighbors on top of the compactor, the ceiling will be damaged. The material will swell and lose its properties, and the stretched canvas will sag. Repair will cost no less than installation.

You can use materials that do not absorb moisture. For example, extruded polyurethane foam. But with its large thickness it does not belong to the most effective in the fight against extraneous noise. On the contrary, with improper installation, it only aggravates the situation.

Also, when deciding to install sound protection, you must take into account the types of noise that occur in a house. By themselves, extraneous sounds equally disturb and annoy. But to know their prevailing appearance is important, since material with different properties is needed to eliminate these or other sounds. Some will reflect the sounds, others absorb.

Noises are:

- Acoustic. This is an echo or reflection of sound from the walls of the room. Such a problem is characteristic of spacious apartments, rooms with arched ceiling vaults and high ceilings. This is a rarity in a modern panel house. But if a neighbor plays a musical instrument badly or listens to peculiar music, it will be heard without an arched vault.

- Aerial. The quietest type of noise, as they are caused by air vibrations. These are the sounds of doors being opened and closed, voices, steps. They penetrate from a neighboring apartment in a complicated way: through cracks in the floor and walls, sockets, ventilation shafts.

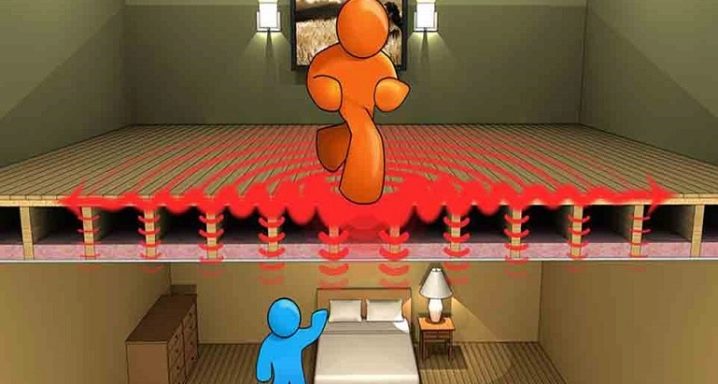

- Drums. Continuous repair from the neighbors, the sound of a hammer, a tramp are types of shock noise. Their source is a mechanical impact on the floor or walls in the apartment on the floor above.

- Structural. These are sounds that propagate through the constructive parts of the building: ceilings, ceilings, walls, ventilation.

The material from which the high-rise building was erected is also important. One may be more dense and less sound transmits (this applies to a concrete structure with thick floors), the other - from porous materials, through which any noise (blocks) pass unchecked, and still others are somewhere between them (bricks).

In a modern panel house, the quality of the material may be different.In one case, the noise is almost inaudible, in the other it may seem that the walls and ceiling are literally made of cardboard, so the insulation is low. The full-bodied brick differs in a good indicator of sound insulation. It does not need a complex structure and a thick layer of additional insulation.

More difficult is the situation with monolith-frame houses, where hollow bricks and porous blocks are used for internal partitions. They miss a lot of sounds. There will have to try to sound insulation ceiling gave the desired effect.

Problem case - new panel houses. They have a large number of slots through which all sounds penetrate both from above and from neighbors from the side and from below.

Soundproofed ceiling in such a house is indispensable. It is recommended to take care of both the walls and the quality floor screed.

Separate conversation - insulation in a private house. As a rule, it is required to reduce the noise level on the first floor or in the rooms under the residential attic. Here materials can be both concrete, and brick, and wooden.

With wooden floors, contrary to the ideas of many, enough problems.First, wood is a good conductor of sound. Secondly, with poor floor installation, the sound will seep through numerous slots. Over time, wooden floors will begin to creak, and worse than this sound is hard to come up with.

With a high ceiling height (4.5-5 meters) there are practically no problems with sound insulation. Such ceilings are usually found in the houses of the old foundation, and in them all the walls and ceilings are so thick that the sound on the other side is unable to overcome them.

Another thing is the modern imitation of such buildings. In them, the problem with noise is relevant, and one of the most common situations is acoustic noise. This does not affect the choice of insulation material. With five-meter ceilings, you can afford to install a layer of any thickness. Here the features of the installation work are more important. Independently carry them out is already dangerous, but in order to get to the very ceiling, you need to build scaffolding.

The best option is considered to be rooms with a height of about 3 meters. At this height, you can make installation work yourself, and taken 10-20 cm from the height will not significantly affect the interior.

The most difficult case - "Khrushchev" and the room with a ceiling height of not more than 2.2 m. They and without a tension canvas look squat and limit design possibilities. When a few centimeters are taken from such a height, the ceiling begins to visually “crush” from above.

To solve this problem, it is recommended to choose materials of minimum thickness. In this case, it should be soundproofing materials, and not insulation. The option of mounting is better to choose frameless.

The most effective (but least likely) option is to enter into negotiations with neighbors and at their own expense lay a thin layer of sound-proofing material on their floor. It is much more reliable than to protect against noise only from its own side.

Types of materials and their characteristics

Modern sound insulation materials are virtually identical to insulation for walls and ceilings. All the same sheet, slab and sprayed materials are used as a means of protection against extraneous noise in the apartment. The use of foam rubber, cotton wool of various origin is widespread: rolled mineral wool, ecowool, basalt or stone wool, based on fiberglass.

Often used materials such as foam and its modifications in the form of foam and polyurethane foam (polyurethane foam). They are plates that are conveniently cut into fragments of the desired length and width. The thickness of such materials is usually greater than that of others, since they are coarse-grained and porous. The exception is sprayed polyurethane foam, but it is rarely used in the construction of ceiling noise insulation.

Also glass can be foamed. Available in sheet form and in spray cans.

Soundproofing products based on plant and natural raw materials are gaining popularity: cellulose, cotton, bamboo and coconut fiber. If it is risky to use ecowool under the stretch ceiling, since there is a risk of dust, then bamboo and coconut fiber with their unique properties can compete with cotton and foam. In the literal sense, healthy (antibacterial repel dirt, biostable), but expensive. Sound insulation is not the most effective.

Also not the most effective, but suitable for apartments in brick houses and private cottages material - cork sheets.Insulation is obtained thin and saves in not the most deplorable cases.

The quality of cork material is improved by a layer of plasterboard, but in this case its advantage is lost - a small thickness.

As an alternative, manufacturers began producing combined self-adhesive materials. This is the so-called membrane sound insulation. In fact, the sheets of the membrane are glued to the ceiling like linoleum to the floor or wallpaper is very thick. As part of a felt and materials that reflect the sound.

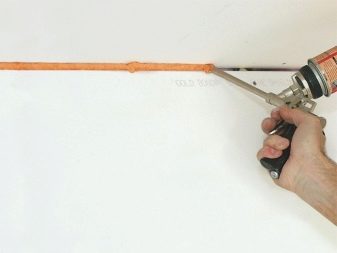

From modern means liquid insulation is noteworthy. It is applied to the working surface with a special gun, but is not used by itself, but serves as a “filling” in the layer between the sheets of drywall.

Foam rubber

Insulation foam is almost the same as insulation polyurethane foam. This name has become a household name due to the fact that the main supplier of polyurethane foam in the times of the Soviet Union was called “Porolon”.

Of course, the insulation material differs radically from that thick, loose yellowish dust collector, which many people represent when they say “foam rubber”. Even the name of his corresponding - acoustic foam.

It is actively used for sound insulation in recording studios, large offices, restaurants and other places where silence is necessary for high-quality and productive work. The material is produced in the form of plates of different sizes and shapes, its outer surface is embossed (wavy or "toothed").

Advantages of foam rubber in that it is simply mounted (self-adhesive or on glue mortar) gives a good result, flexible and flexible, which allows using it on the ceiling with rounded corners. Easy to cut, does not collect dust.

Acoustic foam rubber isolates not only sounds coming from outside, but also coming from the room. Neighbors will be grateful for this isolation. The disadvantages are that it requires careful handling and is subject to burning. In the process produces toxic smoke and loses its properties under the influence of ultraviolet radiation.

Mineral wool

Often this material is chosen to make noise insulation and thermal insulation at the same time. But nevertheless it is more intended for warming, than for achievement of norms on decibels recommended by SNiPs.

Cotton wool reduces noise due to its fiber structure, between which there are air gaps, and different thickness of the fibers themselves.

For maximum effect, it is recommended to lay the sheet of plasterboard on top of the wool slabs and under them.

Cotton wool is of three types: mineral, stone and glass wool. Each variety has its own characteristics, fiber size, specifications.

All types can be used for sound insulation, but the density of the material must be taken into account. The higher it is, the more reliable the insulation will be. For example, from cotton wool with the marking P-75 will be of little use, and PPG-200 is able to solve the problems with sound insulation with different types of noise.

Stone wool has the highest density. With an increase in density, the price also increases, but insulation is not the case when it is worth agreeing to half-measures for the sake of economy.

The advantages of the material is that it meets all building standards, it lasts a long time, does not accumulate dust, does not emit toxins, and is resistant to deformation and shrinkage.

The disadvantages include a thick layer of the entire structure as a whole, the instability of cotton to moisture, the need to use waterproofing. Without protection against water, which may fall on cotton wool when a neighboring apartment is flooded, the material will swell, become heavier, lose up to 70% of properties.Drying or replacing it will be a separate problem. Over time, mineral wool shrinks.

Styrofoam

The material is known as extruded (foamed) polystyrene. Its predecessor is foam plastic that everyone has seen at least once in their life.

Polyfoam can also be used as a sound-insulating material, but the result from the use of polystyrene and its derivatives can not be called impressive. With a slab thickness of 40-100 mm, it still needs auxiliary materials that absorb and reflect noise.

Styrofoam has some advantages. For example, it is suitable for insulation in rooms where the problem of noise is not as acute as in thin-walled panel new buildings. It has a low weight and does not load the suspended ceiling.

You can do without mounting the frame in some cases. It also costs significantly less than mineral wool or acoustic foam, and is hydrophobic. If water leaks from the neighbors above, the material will not suffer and will not lose its properties. For these reasons, the ceiling is insulated with foam plastics.

Penofol is used as an auxiliary element.Penofol is a small thickness reflecting material based on polyethylene foam.

Such layering practically does not give results in terms of noise insulation. All materials are more focused on maintaining heat in the room.

Cork

Many people choose insulation with a cork, because the manufacturer promises serious noise reduction indicators (about 20 dB). But if you think about it, the numbers are deceptive. And the point is not that the traffic jam is not capable of reducing the noise by such a number of dB, but that this noise level does not exceed the sound of a human whisper or a ticking clock. This is nothing when it comes to regular tramping on top, continuous repair and other unpleasant sounds.

But low efficiency is not so bad. The problem is that cork materials are able to isolate from shock noise. That is, they drown out the sound only when the insulation is arranged not under the ceiling tension, but on the floor of noisy neighbors above.

In other cases, the effect is achieved only through self-suggestion and a small air gap between the stretch ceiling and cork sheets. If we have already stopped the choice on cork insulation, then it will be right to combine it with other materials. For example, sheathe drywall. This will increase the chance of finding the desired silence in the house.

Advantages of the material are reduced to the fact that it is convenient for installation work. Cork substrate weighs little, easily cut, just attached. The disadvantages of the material, in addition to the fact that it is almost useless in itself, is its fear of moisture and the need to use waterproofing.

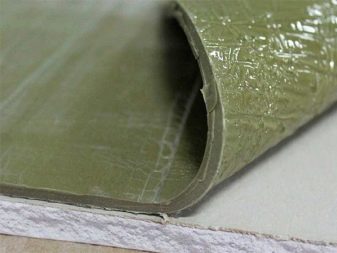

Acoustic Membranes

The latest generation of materials presented on the market in the form of thin sheet materials, plates and tapes. Sheets can be record thin - only 3 mm. Maximum - 15. Sheets are stacked on the surface of the ceiling (floor, walls) and between materials. They help protect against shock noise. Ideally, the material should be laid on the floor in the apartment where the noise source is located.

Tapes isolate such paths of extraneous sounds in an apartment, such as ventilation pipes, drains, slots, risers. They are aimed at reducing acoustic and airborne noise. Membranes are made by several companies in Europe and Russia. The most popular are Tecsound, Topsilent, Green glue, Zvukoizol, Shumanet.

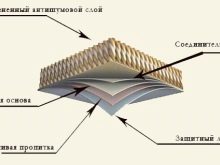

Each manufacturer has its own secret. Most often, the material consists of several thin layers, has a large weight and high density. Acoustic "sandwich" is obtained from the combination of several layers of foam felt, polyurethane foam or polystyrene.It may also contain components of rubber, eco fiber, foamed glass, stone wool, rubber, foam, plasticizers, mineral and vegetable components, and reflective materials.

Plus of the membrane is that it is a roll material of small thickness, which is glued to the ceiling or stretched under it and does not take up much space. This makes it possible to solve the problem with extraneous sounds and not to lose precious centimeters in a small-sized room with low ceilings.

Easy and convenient installation of thin rolled material. A special glue is provided for it, which is diluted as wallpaper. Some types have a self-adhesive backing. The disadvantages of the material is that with large drops in the height of the ceiling, it will first need to be leveled. If the rolls will lie with warps, they will become less effective because of the gaps in the canvas.

In addition, the material is heavy. For the installation will require at least two pairs of hands. And it also means that the base of the ceiling must be well processed and primed to increase the adhesiveness. Price per roll is not the most pleasant.Membranes of European production cost about 8000-9000 rubles. In roll 3 meters.

Other options

There are a lot of alternative options for sound insulation of the ceiling. Both specialized and adapted materials are used. Since it is still covered with a decorative stretch ceiling from above, only the quality of the insulation is important, not its appearance.

Materials used for insulation:

- Granular elastic shumoplast. These are small balls of extruded foam with the addition of rubber and an acrylic base. Traditionally used as insulation under the "floating" screed floor, but in the compressed form it is convenient to use as a material for the layer between the stretch ceiling and the ceiling of the upper floor.

- Acoustic Sealant. This is a liquid substance that does not cover the entire area of the problematic surface, but treats individual zones. These are seams, joints of slabs, cracks through which extraneous sounds and vibrations penetrate into the room. The product is based on silicone resins and mineral additives. Compatible with any materials.

- Panels and Substratesdesigned for insulation under the floor covering. They give the maximum effect, if they are laid in the apartment of the neighbors above, and then mounted under their ceiling. Silence will almost library.

- Damping tape. This is a budget alternative to acoustic tapes for the treatment of ventilation shafts, joints and cracks. It costs many times cheaper, and is almost as effective as it is. In addition, the main purpose of the damper tape in repair is to prevent cracking of the walls, as a rule, after pouring the cement screed. And this is a very large load, which indicates a high density and strength of the tape.

- Drywall Not used by itself. Usually acts as an intermediate component or, on the contrary, closes other materials on both sides. It is combined, as a rule, with thin sheet materials or liquid isolation.

- Bitumen based roll materials. They are oil bitumens, cellulose fiber or felt, modifiers. Used mainly for floor insulation, but suitable for the ceiling. Due to the small thickness, but good efficiency, it is advisable to use them in rooms where space saving is important. Can be combined with other materials.

- Mastic to absorb vibrations and sounds. It happens on the basis of silicones, resins, bitumen, acrylic. It is applied in liquid form in several layers.

- Sprayed cellulose insulation. Eco-friendly and effective insulation, but has several significant drawbacks. This is the high cost of material and procedures, the need to use special equipment, difficult dismantling.

- Sprayed foam. It has the same advantages and disadvantages as cellulose spraying. All materials applied in this way require pre-treatment of the surface of the ceiling, which will improve adhesion.

- Sprayable fiberglass. The most expensive, but also the most effective of the sprayed options. If the financial issue is not acute, you should give preference to it.

- Wood Fiber Materials. There may be several types of them. Plywood is cheap and cheerful, but not very efficient, unlike eco-slabs made from softwood. In difficult situations, when the noise level exceeds 25 dB, eco-plates will not be able to help. Also, they can not be used in a room with a low ceiling - they will take 10-14 cm in height.But plates have an important advantage: they already have a decorative surface on the front side. Suspended ceiling is not needed.

Slabs with a different design of the outer side (imitation of the texture of wood in different colors) are snapped on the thorn-groove principle, like parquet boards. This reduces the financial cost of finishing the ceiling and saves time.

- The third type is soft fiberboard.. They are made from large wood fibers without any additives. The wood is cleaved and then “dumped” like wool. It is used as a felt material, but has a large number of positive properties. Among them - antibacterial properties and the ability to disinfect the air in the room. However, needles can cause allergies.

For allergy sufferers, birch fibers or plate material based on raw materials of coconut, flax and bamboo are more suitable. Such plates can be mounted both by themselves and under the plasterboard layer.

- Eco-plates from volcanic raw materials and glue. Particles of volcanic origin that have undergone a special treatment (expanded clay, perlite fibers and others) are glued together using the safest glue - PVA.Such sound insulation is recommended for use in children's rooms.

- Polyester hypoallergenic fibers. Polyester is also used in children's rooms and rooms where people live with allergies or asthma (the material does not accumulate dust).

- Multilayer cardboard filled with quartz sand. One “block” of such cardboard weighs about 10–15 kg, which makes it dense, and the density of the material is a guarantee of its effectiveness in dealing with noise.

Mounting technology

Soundproofing the ceiling with your own hands - quite doable task. But this does not mean that you will not have to face some difficulties.

For example, installation of lightweight porous materials, which is carried out in one hand, requires a smooth working surface and preparation. And the installation of heavy roll materials such as acoustic membranes is not carried out alone. Although they are 3-15 mm thick, they weigh about 30 kg. To lift such weight on outstretched arms above oneself is not only hard, but also traumatic.

Another important aspect is that the insulation of the ceiling only with an insulating material is considered partial.An effective system should cover all surfaces of the room.

Since sound tends to pass through cracks in the walls, ventilation and ceilings, and noisy neighbors can live not only on the floor above, it is necessary to isolate the entire room as a whole. It is many times more expensive, longer and more difficult than the ceiling, and also affects the useful and visual volume of the room.

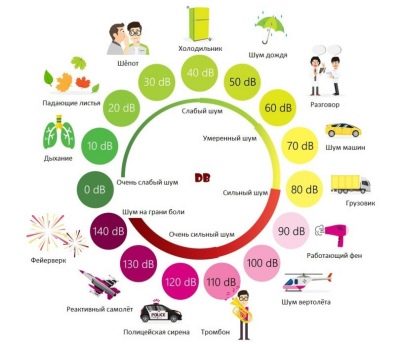

But effective sound insulation is often not the one that is performed in a private apartment, but one that is located in the same room with the source of noise. Only understanding neighbors will agree to lay insulating materials on the floor in their apartment. Even at the expense of others. All this does not mean that attempts to rid itself of extraneous noise by soundproofing the ceiling will not work. They are capable of damping an average of 30 dB.

To understand what the result will be - minus 30 dB of noise - you need to listen to the refrigerator in the kitchen, and then turn it off for 5-10 minutes. The difference will be noticeable immediately.

The success of the event depends on two things: the right choice of insulating material and high-quality installation. A universal selection criterion is the type of house.In some cases, the height of the ceiling also plays a role, but here the decision must be made individually - whether it is worth sacrificing 10 cm of the height of the room or better to come to terms with extraneous sounds.

In a brick house you need materials to isolate air (acoustic) noise. The construction of brick high-rise buildings is not solid, so the shock sounds go out as the apartment is removed from the source of noise. By itself, a brick transmits worse sounds. But they are more common problem with airborne noise. Therefore, it is important to use lightweight, but multi-layered structures.

For example, soundproofing from plasterboard and cork materials, alternating plasterboard with polyester blocks or wood fiber boards will be a good defense. Suitable and drywall with polyurethane foam, mineral wool, liquid insulation.

In the panel and monolithic house the problem is the same - the distribution of shock noise almost throughout the house. If the neighbors started repairing from above, everyone will know about it. But the lower and upper floors - in the first place. This is explained by the fact that a monolithic house (as already understood from the name) is an integral structure in which all partitions and walls are of the same thickness. And if the plates are also hollow inside - this is a double problem.

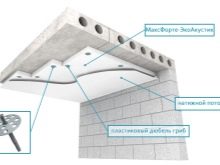

When choosing material for sound insulation in panel and monolithic houses, it is important to take into account the thickness of the floors. If it is less than 220 cm (and this is often a phenomenon, in “Khrushchev-like” - about 120 cm), you must first eliminate this drawback by “increasing” the thickness. Here, light materials and the creation of "air" interlayers between the suspended ceiling and the finishing of the ceiling will do. And after the elimination of problems with insufficient overlap thickness, thin but very dense material should be mounted.

The peculiarity of dense material is great weight. Acoustic membranes, blocks of cardboard filled with quartz sand, basalt wool, OSB-plates are suitable.

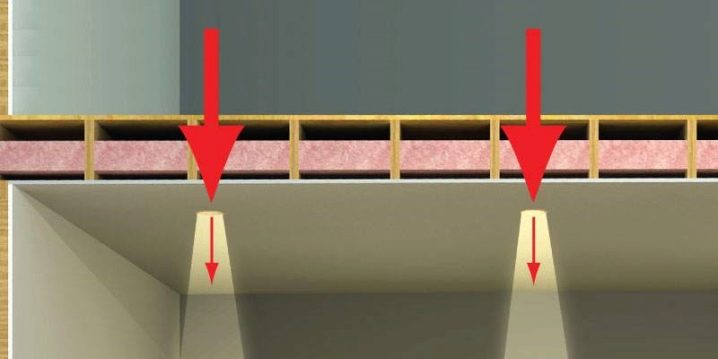

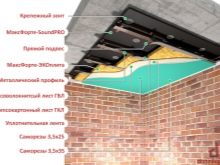

It is important to bear in mind that soft materials predominantly absorb sound, and solid ones reflect. No material performs these functions at the same time, therefore it is recommended to use multi-layer. First, sheathe the ceiling with reflective materials, then mount the absorbing material and reinforce it all with an air cushion between the stretch ceiling and insulation.

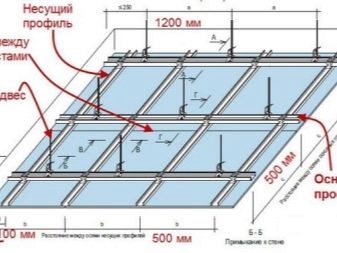

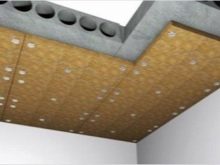

From the point of view of installation technology, sound insulation on any surface can be frame and frameless.

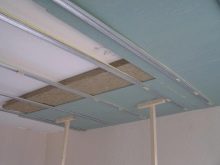

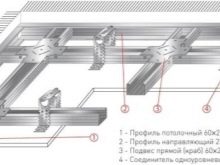

Frame

It means the device of a framework from a steel (more rare - wooden) profile on which sound-proofing materials keep within. This technology can afford the owners of apartments with a ceiling height of about 3 meters. Otherwise, the frame construction will “eat” a lot of the useful area of the room.

Installation is carried out in stages.

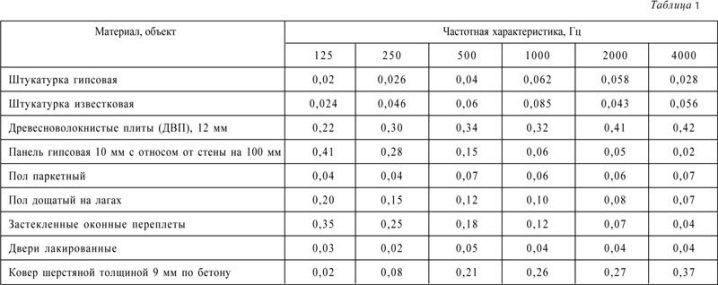

Calculation of materials

This is a difficult and crucial stage, which includes several steps.

Step one is the calculation of the sound insulation index. It can be determined by the thickness of partitions and finishing materials. It is better to turn to experts, because it is easy to make a mistake. For self-measurement, there are such guidelines: during the day, an acceptable (not “non-irritating”) noise level is up to 40 dB, at night it is up to 35.

The overlap between apartments of 200-220 cm plus a floor coupler for neighbors on top is able to isolate noise up to 54 dB, provided that they are carried out conscientiously, in compliance with building codes and regulations.

For comparison, the cries of an adult and the crying of a child are 70-75 dB. No partitions according to SNiP will not protect them. From this it follows that for effective noise isolation, it is necessary to “build up” the ceiling thickness to at least resistance to 60 dB.

To overlap with a thickness of 220 cm with a high-quality tie, neighbors on top will have only one layer of cork and drywall. In a thin-walled panel house will have to make more effort.

A simple way to calculate the protection you need is to listen to sounds from a nearby apartment. The sound of steps - about 30 dB, talk - 45, scream - 70.

Step two is the calculation of the absorption coefficient. This procedure is difficult for the layman. It is recommended to choose materials with a noise absorption coefficient from 0 to 1.

Step three - calculation of the amount of materials. Here we are talking not about the thickness, but about the total amount of all materials. It is calculated quite simply. It is necessary to measure the width, length and height differences of the ceiling. Multiplying the width by the length will give the total area. Then this number should be divided by the footage in the roll or the size of the slab of slab material to calculate how many sheets or how many slabs you will need on the ceiling. The resulting number is rounded up, plus 10% of the material for the stock.

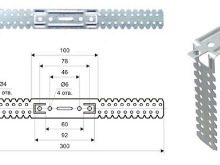

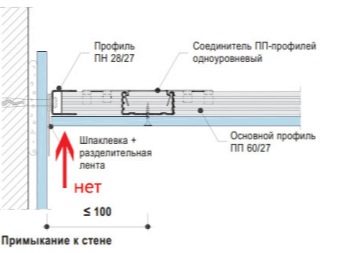

The length of the profile for mounting the frame must take into account the length of one strip and the width of the step. The width of the step through which the strips are mounted should be equal to 30-40 cm plus rubber for gaskets in the places of fastening the plank to the ceiling.This is an important point as the metal conducts sound perfectly. Without rubber pads, the frame will only exacerbate the problem of unnecessary noise.

The calculation of fasteners and glue is carried out according to the recommendations of the manufacturer of the profile and materials.

For hydrophobic materials, waterproofing should be provided. This material is also purchased by the size of the area plus 25% for overlaps and wall allowances. For fixing on the wall need a damper tape.

Preparatory work

They include a selection of tools and materials, working surface.

Required materials: steel profiles, perforator, fasteners, screwdriver, level, tape measure, putty, sealant, sound-absorbing fibrous materials (for crevices), elastic rubber gaskets, metal shears, sound-absorbing and sound-reflecting material. You will need step-ladders or sustainable high construction.

The preparation of the working surface involves cleaning the ceiling of old lime, paint, decorative materials. It is also important to make its surface as flat as possible in order to mount the frame without distortions.

For leveling ready mixes are used.It is important to consider that before leveling the ceiling should be primed in two layers for better adhesion with the substance, and then give each layer a good dry. Self leveling layer can dry from 1 to 3 weeks. Mount the frame on the wet ceiling can not.

Processing gaps, risers and joints on the ceiling-wall border

Processing gaps, risers and joints on the ceiling-wall.

According to building standards for high-quality sound insulation between floor slabs there should not be a gap of even a few millimeters. Otherwise it creates an unimpeded way for sound penetration between rooms. In fact, this rule is often neglected.

You can correct the situation if you clean all cracks from debris and dust and fill them with a non-hardening sealant. Suitable acrylic. Large gaps can be pre-laid materials of felt or wood fiber, and then ensure their tightness.

With risers, the situation is reversed. When building a house, they are supposed to be isolated from the ceiling by a special nozzle, and the risers themselves should be sealed from the nozzle by a sealant. For the sake of saving time and budget, the stage with nozzles is passed on almost any object.Due to the temperature difference inside the pipes of the risers, they expand and contract, gaps and cracks appear between the walls of the pipes and the masonry. It also reduces the effectiveness of sound insulation. Such areas require filling with a non-hardening sealant. Top areas treated with sealant, you need to putty.

Together with the closure of cracks it makes sense to handle and sockets with electrical shields. They have no direct relationship with the ceiling, but they are also sources of noise transmission. It is important to take into account two points: the processing of gaps and cracks around the sockets is done only after a power outage, the materials must be non-combustible.

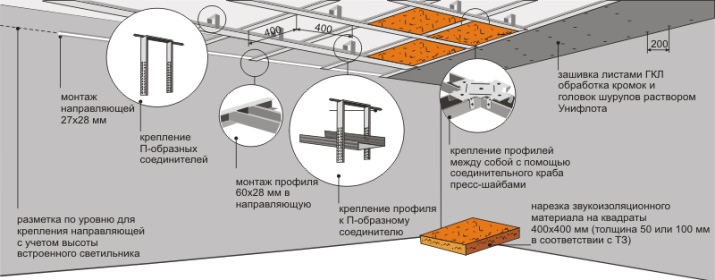

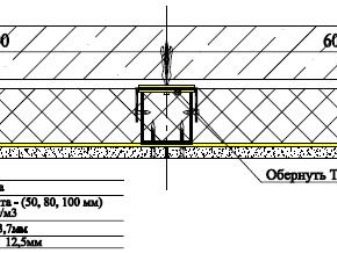

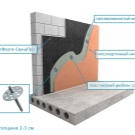

Mounting frame from profiles

Step by step:

- Installation of noise insulating material. It has a small thickness and high density, and also levels the surface before installing the profile.

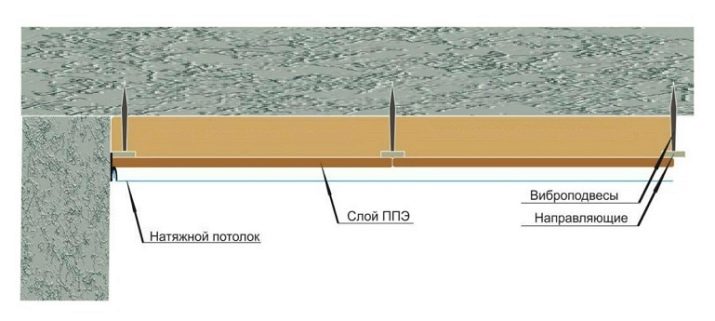

- Installation of anti-vibration suspensions. These are small details on which the guide profile is attached. Either the suspension should be provided with a vibrating support, or they should be mounted on an elastic rubber gasket. Step - from 50 to 90 cm.

- Mounting guide profile.The profile closest to the wall is a maximum of 15 cm from the wall. The pitch is determined independently - from 50 to 60 cm. Fastened to the suspensions with screws of 4 pieces per 1 suspension. The guide profile can be increased in length.

- Installation of an auxiliary profile. It fits across the guides. Step - 40-50 cm. The exact distance is chosen in accordance with the sheet material, for example, drywall.

- Filling the profile with sound-absorbing material: cotton, plates, sheets.

- Mounting frame. Basically, it is made from drywall in 1-2 layers. Sheet thickness - 10-12 mm. If two layers of drywall are mounted, the joints should not be the same. In order to run up the joints, the sheets of the upper layer are laid in a different direction. Joints are treated with acrylic based sealant. He also seals up the joint at the points of contact between the drywall and the walls.

- If the construction touches the risers, then the pipes should be glued over with a damper tape or similar self-adhesive material.

Installation of decorative coating on the ceiling

When soundproofing without mounting a frame made of steel or wooden profile materials are attached directly to the surface of the ceiling.Dowels and screws, special fasteners with wide caps and elongated legs, glue are used for fastening.

Such noise insulation is used when the ceiling height does not allow to deprive the premises of several tens of centimeters, for example, in the “Khrushchev”. The second case - the operational condition of the house, which does not allow to mount too heavy construction on the ceiling. The third is when materials and technologies that protect against noise from a neighboring apartment were used in the house already, but these measures need to be strengthened with additional insulation.

Frameless

Frameless insulation is also mounted in stages:

- The selection and calculation of materials is similar to the calculation for the structure on the frame. If you plan to apply sheets or plates in two layers, then the amount of materials on the ceiling area is doubled. Dowels for fixing the panels are used only plastic, because the steel will conduct sound and reduce the efficiency of the structure.

- Surface preparation. Many materials are glued to glue or have a self-adhesive backing, so for frameless sound insulation it is especially important to process the surface of the ceiling.But before that, all height differences and irregularities are eliminated. The whole preparation includes three important steps: cleaning the surface from paint, dust, decorative coating; expansion of cracks, blowing and filling them with a sealant, applying an alignment layer. After the leveling layer dries, the surface must be primed in two layers.

- Mounting material. Here are several options. It can be glued on a self-adhesive backing, glue or mounted on dowels with a hat in the form (fungus). It is wide, flat and with perforated holes and holds well the slab cellular or fibrous material. The best option is to mount the product with glue, and for additional insurance, install dowels in 90-100 cm steps.

- Machining joints. Plates and sheets are not adjacent to each other tightly. It is recommended that the joints be sealed with a damper tape or filled with sealant. You can layered materials in 2-3 layers.

Useful recommendations

Repair professionals recommend adhering to a few simple rules that increase the effectiveness of sound insulation in the apartment:

- Carefully clean the plaster, paint and whitewash from the surface of the ceiling.The better prepared the work surface, the stronger the frameless insulation will hold.

- If the height of the room allows, choose a suspension frame, and not frameless sound insulation.

- The best insulation, especially for the first floor, is not partial (only the ceiling), but full (walls, windows, doors).

- Avoid cheap materials. High-quality sound insulation worth good money. Budget material does not give the maximum effect.

- When choosing ready-made acoustic membranes, pay attention to the reviews and manufacturer's reputation.

- Prioritize weight and density, not material thickness. 20 cm foam is less effective than wood boards 4 cm thick.

- Combine sound absorption and sound reflection materials.

- Improve the effectiveness of noise insulation by embedding cracks, joints, processing gaps around outlets, risers, electrical boxes.

For how to install frameless sound insulation on the ceiling, see the following video.