Siding features with wood imitation

Wood has always been considered one of the most popular materials in the construction industry. Attractive appearance, excellent performance and ease of care are highly valued by many consumers. At the same time, the cost of natural wood trim can not be called affordable.

As an alternative, it is worthwhile to consider the modern version of the cladding, which is in no way inferior to natural material - this is siding with wood imitation.

Special features

Front siding is a popular finishing material. It is very popular in the exterior design of private and municipal buildings, houses, cottages, bathhouses. Today, manufacturers represent the widest range, numbering many shades and styles of products.

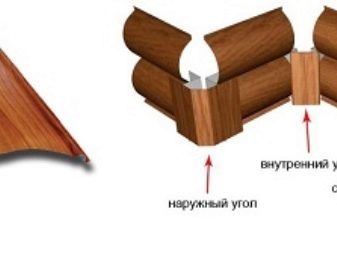

Due to this diversity, each consumer can easily choose the best option for themselves. On sale there is a siding with imitation of the rounded log, a board which cannot be distinguished from natural materials not everyone. Moreover, the panels exactly repeat not only the pattern of a particular wood species, but also the diameter of the logs.

The most "natural" species are recognized panels with imitation of such wood species as:

- sandalwood;

- Pine;

- oak.

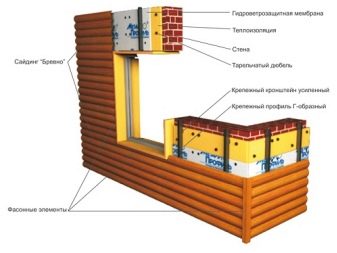

Often hiding engineering communications or pipes under the siding, which makes it possible to create the perfect facade without unnecessary elements. And also it is very popular when creating a ventilated facade - the features of its installation include installation on the batten and insulation.

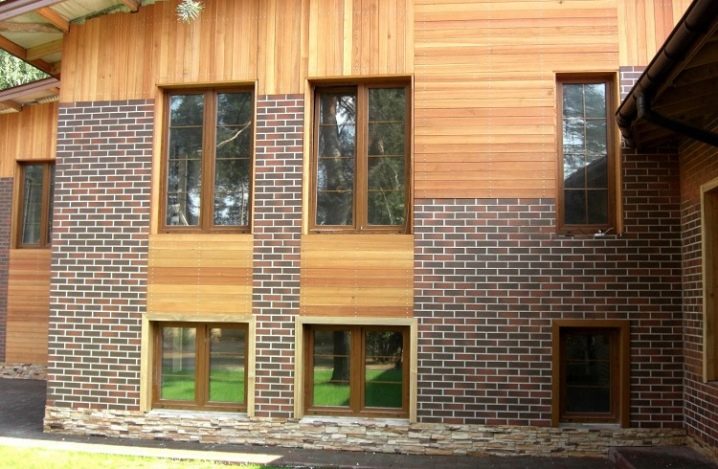

The facade, paneled can "breathe", eliminating the accumulation of condensation on the walls. Siding looks good in tandem with other types of finishing materials. For example, you can create an original design of the facade of a building by combining “wooden” panels with clinker tiles.

Siding from different manufacturers may have different parameters. The length of the product can reach from 2 to 6 m, and in width - 10–30 cm.The thickness of the panel is almost always the same and range from 1 to 1.2 mm.

Kinds

Today on sale there are several types of siding with wood imitation.

Vinyl

Today vinyl (plastic) siding with wood imitation is the most popular. It is made from polyvinyl chloride with admixture of modifiers, binding elements, oxides, dyes.

The advantages of this material include the following:

- long service life - most manufacturers guarantee the integrity of the material up to 30-50 years;

- resistance to ultraviolet, moisture, weather, corrosion, fungus;

- fire resistance;

- tolerates both low and high temperatures - from -50 to + 60 ° С;

- possesses zero electrical conductivity;

- the design of the panels is exactly the same as the tree structure;

- increases noise, sound and heat insulation of the building;

- the low weight of the panels allows them to be used in the reconstruction of obsolete architecture;

- easy to install.

As well as any other building material, besides advantages, vinyl siding has such disadvantages as:

- under the influence of high temperatures, the panels melt easily, with the result that the design of the entire lining is deformed;

- brittleness - although the material is made of heavy-duty plastic, it does not tolerate blows and scratches; even a weak unsuccessful push can lead to a crack.

Despite the presence of significant shortcomings, vinyl siding has been and remains the most popular material among consumers. Popular siding textures are shipboard, block house (with one or more kinks), a slim, single, double or triple herringbone modification. Its dimensions in length range from 3 to 3.8 m and in width from 23 to 27 cm.

Acrylic

This is the so-called modified siding, which includes complex components - acrylic polymers. The presence of additional elements provides high strength acrylic panels.

The advantages of use are as follows:

- resistance to sunlight, which is 10 times higher than the rate of vinyl siding;

- high resistance to aggressive environment, fat, alkalis;

- color range mainly consists of dark shades (arabica, oak);

- tolerate high temperatures well;

- Duration of operation reaches up to 50 years.

The disadvantages include a rather high price, since the cost of products exceeds the price of analog products by about a quarter.

Metal

This type of lining is usually used in private buildings of the warehouse, logistics, industrial type. It is also suitable for facing houses, often found in the design of shopping centers and shops. The material used is aluminum and steel, which act as a base for the panels.

With the help of a special technology, they are coated with a primer and a topcoat, thus creating a multi-layer structure. As for durability, the metal is able to maintain its original appearance for a long time, enduringly enduring bad weather, sun and even mechanical damage. What can not be said about color.

Some panels very quickly lose their color saturation, therefore, acquiring bright color siding, you should be prepared for the fact that over time it will not be so bright. But the products, made in bright soft colors, are able to preserve the original color for a long time.

The advantages of using metal siding are as follows:

- fireproof and suitable for the design of buildings with high standards of fire safety;

- rust resistant;

- tolerates temperatures from -50 to + 80 ° C;

- easy to install and maintain;

- service life is about 50 years;

- diverse color range;

- several types of overlap: polyester, plastisol, pural;

- if you wish, you can order panels according to individual parameters.

To date, there are only a few types of profiles for sale, namely:

- with overlapping of boards (ship board);

- L-timber - imitation of the structure and design of natural wood;

- panels with a pattern in the form of rounded logs.

Fiber cement

In the production of fiber cement siding uses a mixture of cement and sand with reinforcing fiber, which increases the durability of the material and increases its safety.

The advantages of fiber cement siding include the following:

- high strength;

- easy to install and maintain;

- refractoriness;

- ease and safety in cutting;

- resistance to external irritants;

- resistance to corrosion, fungus, mold;

- tolerates frosts;

- not afraid of sunlight - the color does not fade, and the panels are not deformed under their influence.

Of the minuses, you can highlight the rather high cost of products, a large weight of designs and limited color gamut. The texture of the products is not only smooth, but also with embossed or pattern imitating wood. Panels are universal in installation: they can be laid vertically, horizontally and even overlapped. Installation of finished products is quite simple, but cutting is better to entrust experts. In the process of cutting silicon dust is actively formed, therefore, experts recommend that all the preparatory work be carried out in protective clothing and a mask.

Plating fineness

Siding is a fairly simple material that does not cause problems during installation. Knowing the nuances of installation, with the installation of siding with their own hands will not have any problems. Of course, professionals are able to cope with the amount of work much faster. In addition, turning to proven experts, the quality of work is guaranteed to be at the highest level. Therefore, it is better to start self-assembly if you have skills with tools and little experience.

First you need to prepare the facade of the house, removing from it all the extra elements: grilles, shutters, pipes. In the walls and around the window-door frames close up all the cracks. Installing siding begins with the installation of crates.The most commonly used profile is galvanized steel or wooden slats. In the second case, apply only dry slats, treated with special protective agents.

Metal siding is installed on the crate of metal, but for vinyl panels, you can use any. Metal lathing is also used for cladding brick and concrete walls, which is due to the fact that on the brick wall wooden strips will absorb condensate, even despite the treatment of wood with moisture-proof impregnation. When fastening the siding to the basement of the building, you also can not use a wooden crate.

The reason is the same - the tree quickly absorbs moisture from the ground. Difficulties crates occur when facing the walls of aerated concrete. To create a high-quality frame will require the use of more expensive dowels. Due to the fact that aerated concrete is a fragile material, it is difficult to achieve durable and reliable installation.

The next step is the installation of siding. The panels are fixed to the crate, leaving a gap necessary for ventilation of the facade. The problem of condensate accumulation is known to many owners of private homes.If you exactly follow the rules of siding, you can not be afraid of high humidity on the walls and insulating material. Usually the facades are sheathed with a layer of insulation or vapor barrier. In tandem with insulation, they lay a layer of water and vapor insulation, which is mounted directly under the panel.

Facing with siding can significantly extend the life of the building and protect the facade from the weather, sun and external damage.

Tips and tricks

The result of the design of the facade with siding by experienced specialists is characterized by speed and quality of work. Their experience and skill make it easy to cope with even seemingly impossible tasks. In addition, much depends on the accuracy and correctness of the work.

In order to independently install siding with wood imitation, you should familiarize yourself with the following secrets from professionals:

- panels of any siding can not be fastened tightly to each other;

- it is not recommended to drive nails from the edge of the hole or through the panel, it is necessary to do this only in the center of the hole, due to the characteristics of the material, which can be compressed and decompressed depending on temperature conditions;

- nails and fasteners deepen, leaving a gap between its cap and plate;

- the casing should not be done at all; there should always be an empty space in front of the end edge;

- in the warm season, the gap is made about 6–9 mm, in winter they are left from 10 mm; if these rules are not followed, the material is deformed and waves form on the siding.

Beautiful examples

- Wood siding has long become a traditional design of private houses, villas, country cottages. Its strict laconic forms and unique imitation of wooden texture make it possible to transform beyond recognition any facade in a matter of days.

- Modern manufacturers offer such high-quality materials that exactly repeat the structure of wood, that only a professional can distinguish them from natural wood.

- The combination of dark and light shades always looks beautiful and elegant. Cappuccino wall siding perfectly harmonizes with dark walnut framing.

- Finishing siding under a dark wood with white edging will be a great alternative to the usual solutions.

- A variety of colors, textures and parameters of siding allows you to create an individual style of the house.

In the next video you will find installation of siding Holzblock under the log.