Features metal siding under the log

Metal siding under the log is a popular finishing material and is widely used for external and internal decorative finishing of private houses and cottages.

Description

Siding, imitating the appearance and dimensions of natural logs, is made of galvanized steel sheets, followed by drawing on them. The process is carried out on high-tech equipment, allowing to achieve the maximum similarity of the applied image with the appearance of fine wood. From above, the blank, with a pattern applied on it, is covered with a special polymer composition, which ensures high material resistance to environmental conditions and significantly prolongs the service life of the steel. Visually, the material is almost indistinguishable from a natural log, which gives it valuable decorative properties and explains the growing popularity and high consumer demand.. Siding under a log is often called a block house, which means block house.

Included with the panels are often additional elements made in the form of external and internal corners, slats, mounts and trim. The elements are fastened to each other due to the use of the thorn-groove lock construction. The thickness of the steel rolled products corresponds to values of 0.5–0.7 mm, which is the optimal size and allows you to achieve maximum strength of the coating, while greatly facilitating the entire structure. The weight of one panel depends on its length and design, and the width of the slats corresponds to 36 cm. The siding service life is long enough: with proper installation and careful use, such coverage can last from 30 to 50 years.

Advantages and disadvantages

The demand for metal siding imitating a log is due to a number of undeniable advantages of this material:

- The high strength of steel panels is ensured by the presence of stiffeners. Bending siding is quite problematic, which makes the material resistant to external mechanical stress, significantly extends the service life and guarantees the preservation of the original forms for the entire period of operation.

- Excellent fire-fighting properties and complete incombustibility of the material guarantee reliable protection of the dwelling against external fire.

- Due to the optimum thickness of rolled steel, siding does not have a significant weight load on the walls and the foundation of the building, which differs from other finishing materials, for example, from natural stone and decorative brick.

- High resistance to extreme temperatures and high humidity allows siding to be used in any climate zone without restrictions. Due to the low degree of linear expansion that occurs with a sudden change in temperature, the decorative surface is not subject to swelling and deformation, unlike, for example, vinyl linings. The temperature range in which the use of siding is allowed, ranges from -50 to +80 degrees.

- The ease of installation is due to the presence of a universal system of fixation "comb-groove", which allows you to install the siding yourself without using special equipment and attracting specialists.

- The high resistance of the polymer coating to the effects of ultraviolet radiation ensures the preservation of the original appearance of the panels throughout the entire life cycle.When heated, the siding surface does not emit toxic and toxic substances into the environment, which makes the metal coating completely safe and environmentally friendly.

- A wide range of models with a large variety of colors and textures greatly facilitate the choice of material, allowing you to choose panels for any style of house and landscape.

- Long service life.

- Panels wash well, are of no interest to insects and rodents, are not prone to the formation of mold and fungus.

- High decorative properties of the material allow you to quickly transform the old house beyond recognition, giving it a national style and unique flavor.

- The ability to work with the material at any time of the year significantly reduces the time of finishing and eliminates the need to postpone repairs until the onset of heat.

The use of metal siding in conjunction with insulation materials significantly increases the tightness of the structure, reliably protecting it from extraneous noise and cold.

The disadvantages of metal siding under the log can be attributed to the high cost of the material, which is almost twice the price of vinyl counterparts.

Species

Metal siding under the log is available in single and double versions. In the first case, the panel is an imitation of one log, and in the second case, two. According to consumer reviews, two-row models are more convenient for self-facing of houses, allowing for finishing with the least effort and in a short time. The disadvantages of double-row siding is a well-marked joint between the panels and high requirements to the base. There is also some windage of the models, while single-row panels with a wind load behave consistently.

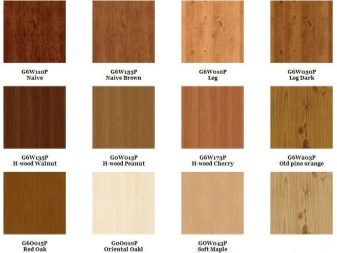

The size range of siding under the log is also diverse. Products are available in lengths from 0.5 to 6 meters, which allows you to choose an individual size and reduce the number of joints, and in some cases even do without them. Despite the large variety of lengths, the most convenient for installation are four-meter models, the increased demand for which fully confirms the ease of installation of this particular size. Colors and design of models are also presented in a large assortment. The collection contains all varieties of oak, including dark, gold and faded shades, walnut and pine are widely represented.The texture of the models is also diverse and takes into account the characteristics of wood of many species. Very natural look panels with exact repetition of knotty, the presence of cuts of annual rings and imitation of roughly treated wood.

Assembly technology

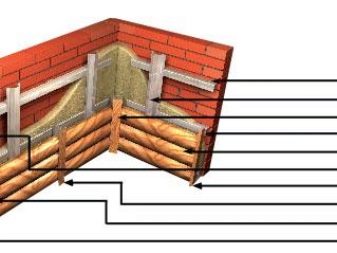

Facing the house with metal siding under the log should begin with a thorough preparation of the wall surface. To do this, remove from them the remnants of the old coating and all protruding elements. If the height difference of the wall exceeds 2 cm by 10 meters, then the arrangement of the batten will be required. In addition to the function of the frame, the lathing serves to level the walls, provides ventilation of the facade and prevents the appearance of fungus. You can perform it from wooden bars or metal profile.

When using a bar it must be borne in mind that its humidity should not exceed 14%. This requirement is due to the fact that during the drying process the material will change shape and the entire decorative surface may be deformed. The metal profile in this case is more preferable due to its high performance and a wide variety of sizes.Elements of the crate should be located at a distance of 40 cm to 1 meter from each other. The step size is chosen individually and depends on the height of the house, the width of the insulation boards and climate features. So, if the building is located in an area with frequent winds, then the distances between adjacent elements of the batten should be reduced, which will ensure the overall strength of the structure and eliminate the sailability of metal panels. In areas located near door and window openings, the distance between the profile guides is also recommended to be reduced.

The next stage of installation should be the arrangement of heat and waterproofing. The most popular materials that ensure the maintenance of a comfortable microclimate in the room are izospan and isover. Insulation plates are placed between the guides of the batten and fixed with dish-shaped dowels. Between themselves, the material is fastened with a construction stapler, and then covered with a diffusion waterproofing material that will protect the heat insulator from the effects of snow, rain, condensate and wind. When fixing the film should be remembered that it should be laid smooth side up.

Next, you should proceed to the installation of additional parts. To do this, using self-tapping screws, attach a starting plate to the batten, placing it 4 cm above the level of installation of the panels. Then in the starting profile it is necessary to make the lock of the first panel, and then fix the panel itself on the profile using self-tapping screws. All other strips should be fixed in the same way, moving from the bottom up. After the siding has been installed, the joining seams are closed with special slats, the ends of the slats are camouflaged with platbands, and the final profile is fixed over the mounting shelf.

Cost of

The average cost of one square siding imitating a log varies from 450 to 550 rubles and depends on the design and texture of the material. The most expensive models are those that have a rough surface and provide, thus, a complete resemblance to a log. The house, sheathed with such panels, even on closer examination is very difficult to distinguish from the natural. The cost of installation works corresponds to the cost of the material and is about 500 rubles persquare, so self-installation of siding will almost halve the cost of finishing. When selling metal siding, many hardware stores offer the service of calculating the required amount of material. To do this, you only need to make preliminary measurements of the walls of the facade and openings, and submit the data to the seller. Further, using a computer program, a detailed layout of the siding on the walls is made and the exact number of panels to be purchased is determined.

Useful tips

Following simple recommendations will help to avoid difficulties when purchasing a material and eliminate errors during installation:

- If metal siding is purchased through an online store, it should be remembered that the tonality in the catalog may differ slightly from the original. For the same reason, it is recommended to buy all the material in one place and from one batch, since models of different series may differ significantly in color.

- When cutting panels, use a hacksaw, metal scissors or electric saw. The use of an angle grinder with abrasive discs is unacceptable, as the siding will heat up during the cutting process,and the zinc layer may collapse.

To avoid deformation, the cutting of panels should be started from the perforation edge.

- When fixing the siding to the crate, it is recommended not to twist the screws a little, which will prevent cracking and damage to the material during its seasonal reactions to changes in the ambient temperature.

- The installation of split systems on a siding surface is prohibited. If it is necessary to install an air conditioner or other massive unit, a special frame should be installed on the wall of the house. Fastening of the structure must be quite rigid and carried out with the help of dowels directly on the supporting wall.

Metal siding under the log is a popular finishing material and is in high demand among owners of country houses and cottages. Competent choice of material and strict adherence to the installation rules will give the old structure a new look, insulate the home and allow for many years to forget about repairing the facade.

To learn how to install siding under the log, see the following video.