Installation rules for ground siding

Ground siding has protective and decorative functions. It has a greater thickness, and therefore greater strength, wear resistance. Among its advantages - affordability, ease of installation.

Special features

The basement of the building is subjected to increased loads and wear, because it is stronger than other parts of the facade, is affected by mechanical shocks and ground pressure. It is subject to the influence of ground and above-ground waters, heaving of soil, chemically aggressive elements.

To prevent the impact of the environment on this part of the facade allows its lining materialsthat perform protective and decorative functions. We are talking about basement siding panels, which are made under pressure by casting from a thin metal sheet. Use of polymeric materials as a basis is possible.

Ground siding has a greater thickness and strength compared with similar wall panels. In addition, it is different in size from the wall analogue, which makes it more convenient to install. As a rule, the height of the panels for the basement is equal to the height of the basement itself, so the material is a small rectangle.

Among the advantages of this technology is its simplicity, the ability to perform actions independently in a few days. Compared with other methods of finishing the basement, this option is the most economical, it does not provide for excavation, purchase or preparation and subsequent pouring of concrete. By themselves, the panels differ in price availability.

Basement panels are not afraid of exposure to moisture and can withstand temperature changes in the range of -50 ... +50 degrees. It is not resistant to ground heaving and in most cases does not exert pressure on the foundation. If necessary, you can lay a layer of insulation under the siding, installing panels according to the method of ventilated facade.

Finally, thanks to the variety of panels, it is possible to give the house an original and distinctive appearance.The panels are perfectly combined with the most common finishing materials and textures.

Kinds

Depending on the material of manufacture, the following types of material are distinguished.

Vinyl

At the core is polyvinyl chloride, thanks to which the panels are light and inexpensive. Among their advantages - moisture resistance, weather resistance. However, the vinyl for plating the base may not be too strong material. With strong mechanical effects, it can be damaged. More durable is considered vinyl siding with the addition of acrylic, which has a higher technical and operational characteristics. Vinyl siding is usually used for small wooden houses. It is affordable and suitable for registration of a country house.

Metal

Unlike vinyl, these panels are more durable, shock-resistant. They are made of metal plates with anti-corrosion protection. Because of this, they are not afraid of moisture, are weatherproof. Metal siding has a slightly greater weight than vinyl, so in some cases (for example, in old buildings) preliminary strengthening of the foundation is required.It is used for finishing private houses from both light (for example, for a log house) and heavier (brick) materials.

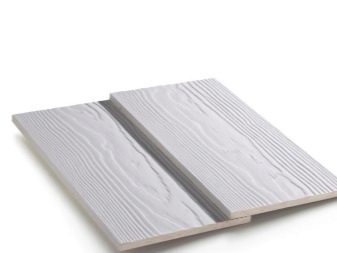

Fiber cement

It consists of fiber cement (usually it is Portland cement in combination with recycled cellulose and additives), which provides maximum strength and weatherability of the base, but has a great weight. This, in turn, limits the possibility of using the material - it is not suitable for all types of foundations and not for every soil. For fiber cement siding should be selected powerful stone and concrete foundations, a prerequisite is the strength and stability of the soil.

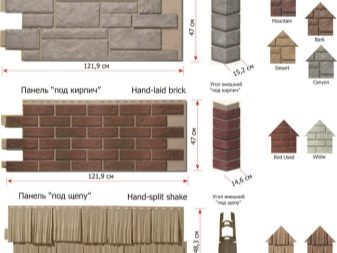

Decorative siding design

As already mentioned, in addition to the protective function, the basement panels also perform a decorative one. Today, manufacturers offer a large variety of profiles in terms of design, including:

Under the stone

The material imitates the surface of a large or smaller natural stone, which gives the object solidity, respectability. As a rule, stones such as pebbles, shell rock, flagstone, and granite are imitated.

Under the brick

Such panels imitate brickwork made of various types of bricks. Due to the fact that the dimensions of the “bricks” in this “laying” correspond to the present, it is possible to achieve maximum realism of the surfaces. Brick siding can be any shade - red, brown, yellow, sand, imitation for burnt, clinker, glossy and aged bricks is common.

Under the tree

It imitates wooden surfaces, which are invariably associated with the environmental friendliness of the house and emphasize the status of its owner. Due to the variety of options it is possible to choose a model that repeats the texture and color of a particular type of wood.

The siding imitating natural surfaces is realistic - it is possible to determine the copy only upon closer examination. At the same time, this material, unlike natural surfaces, is distinguished by its affordability and ease of maintenance. It does not require strengthening the basement due to low weight and special treatment, excavation, and purchase of cement mortars.

Calculation of the number of required materials

In order to understand how much siding is required for work, one should find the value of the perimeter of the surface being trimmed and divide the resulting number by 0.9 (the standard length of the panels). The resulting number is the number of siding in the same row. Further, based on the height of the foundation and taking into account the width of the panels, the number of rows is determined.

When this indicator becomes known, it is possible to calculate the total number of panels required for operation. To do this, the number of rows is multiplied by the numerical coefficient of siding in one row. For example, if the cladding involves 2 rows, then 2 must be multiplied by the number of panels required to lay out one row.

For decoration of corners, special additional elements, corners are used. Their height is equal to the height of the plinth panel, so to calculate the required number, multiply the number of rows of panels by the number of corners in the house. For example, if the panels are stacked in 2 rows on a house in a rectangular shape, then 2 should be multiplied by 4. For the specified object, 8 corners should be purchased.

When calculating the number of starting strips, it should be borne in mind that one plank should be enough for 2 panels, so the number of panels in a row is divided in half. Similarly, you can find out the number of finishing slats.

When covering the plinth, a J-profile may also be required., which is used in the design of internal corners, as well as the refusal of the starting bar on the facade, standing on the uneven surface of the house. In this case, it is necessary to cut the siding, so it remains without fixing hooks. Fixation is carried out by inserting the panels in a pre-cut and fixed J-profile. Calculate the required number of these profiles can be given the profile length (usually 3.66 m) and the length of sections on the facade, which are sheathed J-profile.

To determine the number of tides, you should know the standard length of the tides (in most cases - 2 m) and the perimeter of the building. It is important to remember that the ebb are recorded overlapped, so the useful length of each is not 2 m, but 195 cm.

How to install?

At the first stage, training grounds should be prepared. If the work is done with your own hands, you should clean the surface, strengthen all loose and collapsed elements, close up large seams. Minor defects can be eliminated, the permissible height difference is no more than 2 cm.

All traces of communication should be removed from the surface. If warming is to be done, then for adhesion of the glue it is necessary to remove the old paint (if any) from the base and to treat the surface with two layers of deep penetration primer.

Further along the perimeter of the entire basement of the building is mounted crate. For the base, this should be a metal frame, which, compared to the wooden one, has a greater bearing capacity and durability. The frame is assembled from profiles with high-quality anti-corrosion treatment. The crate step is 0.4 or 0.9 m, the distance from the bottom of the building is 15 cm. If there is a concrete blind area around the house, the starting bar can be installed directly from it.

The distance of the batten from the wall is determined by whether the insulation will be laid under the panels. If not, then the thickness of the profile is sufficient. If the simultaneous heat insulation of the basement is meant, then its height (distance from the wall) is selected taking into account the thickness of the insulation.

The profile of the lathing is fixed with the help of brackets. A paronitic gasket is placed between the latter and the wall, which will eliminate the formation of air voids at these points, which in future turn into “cold bridges”.

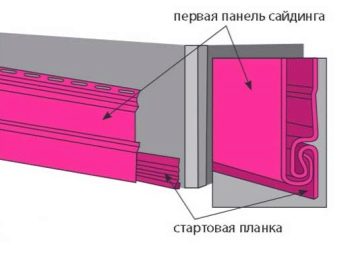

The installation of the first panels is carried out on the starting plate, so the quality of all the cladding depends on its evenness. It should carefully measure the horizontal several times checking the accuracy and evenness. The starting bar is fixed with self-tapping screws, after which you can begin to install the side elements.

The first panel begins to be laid from the corner, hooking hooks over the starting bar and sliding into the groove of the corner. After that, the rest of the first row siding is attached to the starting bar. After installing each 3 panels it is recommended to measure the level, deviations are allowed no more than 2 mm. The second row is fastened to the material of the first row, fixing is carried out in the grooves of the previous row, as well as on the screws.

Before mounting the last row, a finishing plate is fastened into which the upper part of the panels of the last row is inserted.

If the basement insulation is provided, then the step-by-step installation instructions are as follows:

- After installation of the frame, a layer of insulation should be laid between its elements. Mineral wool or polystyrene sheets, as well as polyurethane foam spraying are commonly used.Minvat and expanded polystyrene are glued to the surface, while it is important to achieve maximum tight fit of the material to the walls, including at points near the frame profiles.

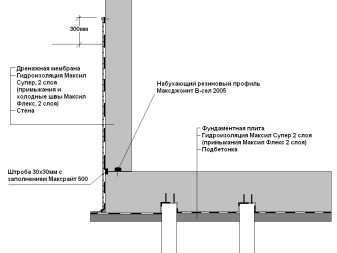

- Installing hydroprotective film, and better diffuse membrane. It is laid with an overlap of 10 cm, all joints are taped.

- It should be further strengthened glued insulation, for which it, along with the membrane, "put" on the screws. On 1 square. m enough 3-4 screws, one of which must be located in the center.

- The final step is to install the basement panels according to the technology described above, with an air gap of 3-5 cm between the layer of insulation and the finish.

When installing on screw piles, backfilling is done first. (the elimination of the space between the surface of the earth and the lower part of the house). Usually this part is insulated, waterproofed and upholstered with wooden boards. After that, the surface is treated with antiseptics, then it can be sheathed with siding. If the surface of the boards is flat, the panels can be attached directly to them without crates. If not, then lathing is performed on which the panels are mounted.

Tips

Siding for finishing the basement will correspond to the declared characteristics only if the original product of a reputable brand is purchased. In this regard, before buying, you should always make sure that the products have certificates of conformity.

Attention should be paid to the thickness of the material and its dimensions. The thickness should be the same over the entire surface. To do this, compare the thickness of the ends of the panel at several points. Dimensions of the material should correspond to the dimensions indicated on the package.

The surface of the panels should be smooth, not chipped and scratched, the color - uniform, perforations - the same, with smooth edges.

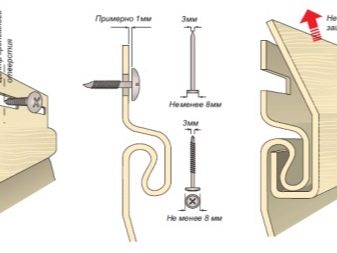

When tightening the screws do not need to strive for their snug fit siding. There should be a distance of approximately 1 mm between the fastener head and the panel surface. Panels are stacked with a small gap. For vinyl panels having a high coefficient of expansion, depending on the temperature of the medium, a gap of 5-7 mm should be left.

When trimming a pile private house, you should first waterproof the piles outside.For these purposes it is convenient to use special mastics.

The use of a metal profile for lathing allows you to get curly corners. To do this, you only need to bend the profile of the desired shape, after making a notch on its surface every 1.5-2 cm. Nails or screws for fastening the panels should be driven exactly in the middle of a special hole.

If there are windows in the basement, you should consider how the slopes will be performed. Usually this is done with the help of a finished wrap.

Beautiful examples

- In most cases, the basement siding is matched a few tones darker than the shade of the walls, and in order to “tie” the house upholstery together, some elements of the facade, as well as the roof, have the same color as the basement.

- The siding under a natural stone and a brick became widespread. Such houses look reliable, monolithic and respectable.

- Slightly less popular is wood trim. As a rule, it is selected for facades that also have wood decoration.

On the peculiarities of the installation of ground siding, see below.