Features of metal siding under wood

The concept of siding (from English siding) has been firmly entered into the building dictionary and has been there for several decades. This designation of the material for exterior plating was used in the 20th century abroad as a protection and decoration of the house with small wooden slats. In the Soviet Union, its prototype was the legendary "wall paneling", which, in order to save expensive material, was used mainly for interior decoration.

Unusual steel trim with wood look

Today, the texture of siding as a cladding,which can be quickly refined facade, is rarely used in its original wooden filling, as natural wood requires constant care, and the price for it has not become too affordable.

Wooden panels were first replaced by plastic or vinyl. After came the turn of the metal siding. New trends in the most natural appearance of housing pushed designers to develop technology for metal trim, painted under the cut of natural wood.

Application areas for new material

The new technology of exterior trim is widely used and has been recognized by building designers as a wear-resistant material with a wide use.

Below are the most popular ones.

- The cladding of the exterior walls of the house is the most obvious solution, which is necessary in the case of simple refining of the facade and protection from moisture. And also this “beautiful packaging” can cover the material for insulation: foam panels, fiberglass mats and other materials that are unpresentable, but useful for comfortable living. In this case, in the case of warming the walls of the house, the “wrapper” of metal siding with a wooden pattern will notnot only look warm, but also soak up the sunlight, giving extra heat to the house.

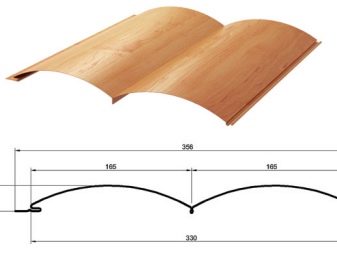

- Particularly popular was the design of the facade in a block house way (from the English block house, literally - a planed board), reproducing the semblance of a building made of rounded logs. A real log, as a rule, is processed using the “square in a circle” technology so that the surface has a straight lower platform and an upper semicircular bend. Metal siding for a block-house bend and give it a similar shape. After finishing with the material copied in form and color, the house acquires the shape of a log house.

- Filling sections of the fence with a new type of siding is a non-trivial solution that combines the reliability of the metal and the beauty of the wooden pattern, which reliably protects the site from prying eyes. Ease of installation is preserved, as the most time-consuming step is to install intersectional supports. Filling the opening will be a fairly simple procedure, since there will be no need for assembling corner locks and securing a large number of adapter strips.

- Roofing is a traditional, but more durable solution,since the polymer-treated metal will last for decades longer, and the “wooden” pattern will emphasize the harmony of the house and the surrounding landscape.

- Interior decoration of some parts of the ceiling or walls due to the applied natural pattern will not look alien, and in combination with glass and brickwork will give the design a high-tech direction.

Material characteristics

Metal siding blanks are made from cold rolled carbon steel alloy. A protective anti-corrosion coating is applied over each sheet. Next comes the “wooden pattern”. This can be a polymer film using the Printech offset printing method or a specialized ink that can reflect sunlight and make the side panel more cold.

The resulting product has fire protection and does not contribute to the spread of flame in case of fire.

It is highly resistant to temperature changes (from –50 ° C to + 75 ° C) without changing the initial characteristics of the material after installation.

The lifetime of the modern material

Depending on the method of protecting metal from corrosion, the service life of metal siding varies from 20 years to lifelong use.

For example, when applying a polymer film - the warranty on the finishing material is from 15 to 50 years. If the siding is made using patented paint, the manufacturer can give a lifetime guarantee against cracking, peeling and fading.

Throughout the entire service life, metal siding does not emit harmful vapors and does not create a danger to human and animal health.

Thermal conductivity

Metal siding has a high thermal conductivity. If the quality of the coating is of low quality, then the facade will heat up on hot days. In the southern climate with a stable high temperature in the summer, it is recommended to install the cladding on the metal profiles without using untreated wooden bars. One of the methods to reduce thermal conductivity is an additional layer of thermal insulation materials.

Material color

The color scheme is quite diverse compared with analogs of vinyl. Some manufacturers offer the service of choosing the texture of the tree from the catalog.

The most common cut patterns:

- oak (bleached or stained);

- Pine;

- maple;

- larch;

- cherry;

- Rowan;

- nut;

- cedar.

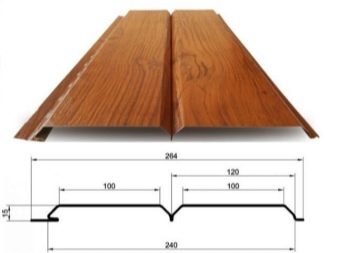

Weight and dimensions

These characteristics are essential for the preparation of the installation structure of the batten. Metal sheets have different sizes. The domestic market, as a rule, offers lanes from 0.5 to 6 meters in length and from 22.5 to 32.5 cm in width. The thickness of one sheet of siding can vary from 0.4 mm to 1.5 mm, depending on the standard set by the manufacturer. The weight of one element starts from 5 kg. An overseas manufacturer can supply wider sheets that visually look like large wooden slabs.

Accordingly, for the installation of iron cladding surface must be reinforced frame. It is allowed to use wooden bars treated with impregnation against mold and fungus.

In some cases, it is necessary to strengthen the foundation and the outer wall, if the structure is old or not sufficiently stable.

When calculating the material, it is important to consider that part of the metal bar at the top and bottom will be blocked and latched onto the locks. Accordingly, the useful area of the facing will be reduced by the amount of fastening.

Care for modern trim

Simple maintenance of the new facade is one of the obvious advantages of metal siding with wooden pattern.In order for the color of the walls to look new, it is enough to wash it with ordinary water a couple of times a year. Do not flush the surface with a powerful jet of pressure from Karcher, so as not to push the metal and not spoil the geometry of the wall.

Facing installation

If the typesetting elements of the metal siding plates are not long, and the size of the surface that needs to be closed is small, then self-installation of a new lining is quite possible. An important point in this decision should be to obtain detailed instructions and a full set of components from the manufacturer.

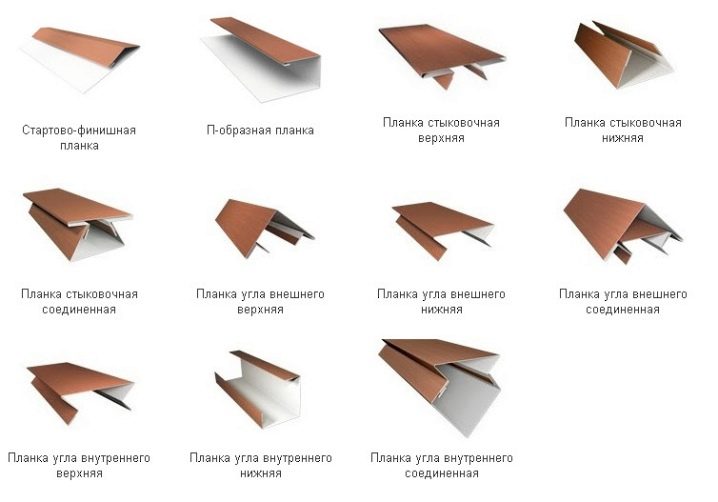

The kit for facing the facade of the house should include:

- corner details, such as caps for butt joints, clearance of openings for windows, doors and open parts of the structure;

- corners internal and external (complex and simple);

- transitional strips (docking, plinth, slope, initial, external and internal angle, upper and lower);

- molding;

- casing;

- water outflow

To eliminate the risk of not fitting the parts - the whole set is better to take from one manufacturer. However, you can decide on different color elements.

For example, to make the main canvas of a wall in a light tone of bleached oak, and to put the platbands and corner facade slats from dark Siberian cedar.If the manufacturer uses the same standard for the manufacture of components, then the color gamut can be selected by the client independently.

The surface under the crate must be cleaned and removed any loosely fitting layers that can crumble under the new facade. After you must apply a protective layer of primer. In order not to level the surface area with metal guides, it is advisable to “bring” the corners of the walls one level with the help of building mixture.

The spacing of the mounting step should not exceed 40 cm, and all openings should be reinforced with a solid array of guides that will withstand constant vibration when using doors and windows.

Insulating material should be positioned as tightly as possible, controlling the smooth lines of the joints, without deforming the surface.

When attaching metal siding sheets, the fastening must start from the middle and move to the edges. Each of the strips should be fixed as carefully as possible in order to prevent deflections or dents, since after damage it will be impossible to restore the material to its previous state.

A critical step for a smooth installation of the structure is the installation of the first starting strip. Subsequent sheets will be attached to it. Its proper mounting will determine the geometry and appearance of the new siding. After that, the result will depend on the correctness of the step-by-step instructions from the manufacturer.

If the refining area is too large, or the selected material has large dimensions, you can always invite professional experts to ensure that the installation is of high quality and the siding is not damaged.

User Reviews and Comments

Reviews of people who used metal siding under the tree for facing a private house, are divided into positive and negative.

- Appearance does not cause complaints in any weather, in a natural landscape looks very organic.

- The surface is heated if the lining is attached to the surface without intermediate insulation.

- If mechanical deformation of one of the sheets occurred, the owner was forced to disassemble the structure from the top to the site of damage in order to replace the fragment of the coating.

- When used for more than two years, the initial characteristics are unchanged.coating without deformation.

- After a year, the edges of the sheet began to rust, which spoils the appearance of the surface under the tree. The problem may be a violation of the technology of metal trimming, or the manufacturer has made a poor-quality coating.

- When operating for more than three years, the presence of insects or rodents is not noticed, since siding with a “wooden” pattern is not an organic material.

The cost of modern material

The price of a new type of siding is lower than expensive natural wood panels, timber or logs, which are leaders in terms of high prices and complexity of installation. However, it exceeds the cost of vinyl siding.

Considering practicality and durability - metal siding with a “wooden pattern” can be the very golden mean that the owner will be pleased with.

Features of mounting metal siding under wood are discussed in the following video.