What plastering aerated outside and inside the house?

Recently, the construction of private houses used aerated concrete. The material has earned wide recognition, thanks to its positive qualities. Such material is produced in fairly voluminous blocks of light weight, so the construction is carried out at a rapid pace.

Special features

Foamy material perfectly retains heat, therefore, you can significantly save on insulation.

The abundance of pores allows the blocks to "breathe." The bad thing is that they absorb moisture. If in the warm season the water dries out without consequences, then in a frost moisture absorbed into the building material will inevitably lead to the formation of cracks.

Plastering of aerated concrete will prevent the penetration of water into the unit, preserving its integrity.

For high-quality performance of work it is necessary to consider the features inherent in the processed material. Not all aerated concrete blocks are the same - their structure may have differences. For example, the outer surface varies.

Plastering sawn aerated concrete can be without prior treatment. The molded block on the outside has a smooth hydrophobic layer. Applying plaster on such a surface is problematic - to increase adhesion, it is necessary to grind the treated side with a metal brush.

We must not forget that the degree of vapor permeability increases in the direction from the inner surface to the outer one, therefore the facade finish should be made twice thinner than the inner coating.

At least six months must elapse before plastering aerated concrete walls. During this time, the walls are completely dry, from them will disappear excess moisture that falls into the blocks during the construction of the structure.

The outer surfaces of the walls can be plastered with decorative materials, compositions for subsequent painting can also be used. Exterior finish sometimes serves as additional insulation. In regions with a cold climate, plastering plays a significant role in maintaining heat indoors.

For aerated concrete, plaster should be selected with optimal parameters. Finishing material is required to protect the walls from destruction on both sides.

Due to the porosity of aerated concrete has received such characteristics as thermal insulation and vapor permeability.

Proper finish:

- helps to preserve the useful qualities of the blocks;

- does not allow condensate to accumulate inside the pores;

- prevents mold and unwanted damage.

Types and compositions

It is impossible to trim aerated concrete walls with ordinary cement mortar. Standard solutions have too high density, so they do not cope well with blocks. Due to poor adhesion, cracks appear on the walls after a short time, which leads to peeling of the plaster layer and exposure of the walls.

Special breathable blends with a so-called vapor-permeable base:

- freely pass steam;

- create a positive indoor climate;

- protect the walls from moisture accumulation inside them.

The following requirements are imposed on plasters for the finishing of aerated concrete:

- resistance to precipitation and ultraviolet, to rapid and frequent changes in outdoor temperature;

- sufficient density;

- possession of high adhesion;

- vapor permeability;

- compressive strength;

- good thermal insulation;

- decorative appearance.

Good plaster meets all listed requirements. It is easy to apply, looks great and keeps on the walls for a long time.

If the facade is not processed, the aerated concrete will first darken, then begin to deform, and its outer part will begin to flake off.

Plasters for exterior work are different from those used for interior decoration of blocks of aerated concrete. The first are more expensive, the second - cheaper. The main difference lies in the ability of the hardened mixture to moisture resistance. If for exterior walls this indicator is essential, then for interior decoration it is possible to do without it. Exception is plaster for rooms with high humidity.such as bathrooms.

The composition of the facade plasters are divided into the following types:

- acrylic;

- silicone;

- silicate;

- lime-cement.

None of the types can be considered ideal - each variety has its own strengths and weaknesses. For example, the vapor permeability of plaster based on acrylic is low, but it has excellent decorative properties. Finish is thin, but very durable.Layer long preserves flawless structure.

It is advisable to use acrylic plaster when applied to the inner walls of good insulation.

The basis of silicate plaster, intended for aerated concrete, is liquid potassium glass. Vapor-permeable coating is resistant to moisture, perfectly resists abrasion and pollution. Durability is a quarter of a century. The disadvantages include limited color gamut.

Silicone polymers and resins are part of silicone blends. The coating is very durable. Unlike other types of silicone plaster retains its elasticity after curing. There are no cracks on the finishing layer even after the blocks shrink. Due to the fillers plaster are given different colors and shades.

The advantages have a significant impact on the cost - the silicone mixtures are the most expensive.

Lime-cement mortars are characterized by vapor permeability and strength. They lack elasticity and water resistance. The problem is solved by introducing special additives into the mixture., and experimenting with fillers, you can get different colors.

Ready mixes are supplied with all necessary - they can be used without preliminary preparation and introduction of the improving components.

For interior work using completely different formulations. At the heart of plaster for processing aerated concrete indoors, there is gypsum.

Before starting work, the blocks should be primed.

The plaster is applied on a flattened surface, free from build-up, dirt and dust.

Works are carried out in several stages:

- padding;

- putting the first layer of plaster;

- installation of reinforcing mesh;

- applying a second layer of plaster.

Wallpaper can be glued to the treated wall after the material is completely dry.. At will it is possible to execute decorative furnish. The decor appears when introduced into the gypsum mixture of fillers in the form of marble chips or perlite. The wall covered with gypsum can be painted.

Training

It is very important that aerated concrete walls are prepared for the application of the finishing layer.

Despite the fact that the outer and inner walls are operated in different conditions, there are general requirements for their pre-treatment:

- both inside and outside the wall must be smooth;

- for both sides, plaster should be selected with maximum adhesion;

- the application of the solution on the mesh is desirable from both sides;

- the master will need a mortar tank, a trowel, a plastering bucket, a grater.

To ensure that the plaster lays well on the aerocrete, the latter should be moistened evenly.. For this purpose, ordinary tap water and a simple sprayer will do.

If there are chipped or cracked, then you have to pick up a trowel and fix the flaws with the solution. Cement mortar will be an excellent restoration material, if the grooves are first treated with a primer.

With the help of beacons, the surface of the walls of the room is displayed in one plane, after which you can begin to perform basic work.

First, the finish is performed indoors and only then outside — otherwise excessive moisture forms inside the house.

Application technology

The appearance of the treated walls and the durability of the decorative layer depend on the correct implementation of the technology.

Below is the sequence of processing the external surfaces of aerated concrete walls.

First you need to inspect the blocks: eliminate all irregularities, clean the cracks, widen and putty with the usual solution.

In the same way it comes in identifying chips and potholes in each gas block. These preparatory work can be done with your own hands - it is quite simple.

Those who dare to personally perform basic work without relevant skills need:

- get the tools;

- follow the technology of plastering;

- not to be afraid of heights (some of the time will have to be spent on a decent height of forests);

- have free time;

- have physical strength.

To ensure that the plaster lays down well and does not lag behind, the aerocrete after stripping with a metal brush is grounded.

The primer requires a special one - it should contain acrylatesiloxane. This ingredient protects the wall from moisture and increases adhesion. At the same time, the composition does not prevent the gas block from “breathing”.

The priming operation in accordance with the technology should be carried out in dry weather and an ambient temperature of about +15 degrees. It is advisable to handle the walls from the side where there is no direct sunlight.

The next step - the tension of the grid - proceed after the final absorption of the primer.

A mesh made of an alkali resistant material is suitable for gas blocks.. Any other material will simply dissolve over time, which will adversely affect the service life of the finishing layer. On the wall, fiberglass reinforcement mesh is fastened with screws so that there is a small space between it and the wall.

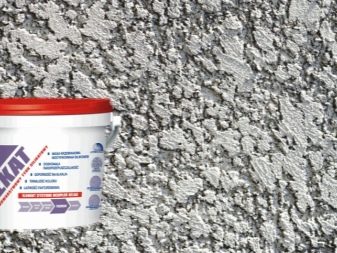

Plastic plaster, specially designed for aerated concrete, is applied to the prepared wall in dry warm weather. Mixtures for foam construction material are quite expensive, but they repel moisture and allow air to pass through. The plaster is applied to the blocks with a wide spatula. The result should be an even thin layer, the thickness of which is approximately 8 mm.

The processing does not end there. Water repellent applied on plaster. After it is absorbed, it is time to complete the finish. The choice can be decorative plaster or paint. In both cases, the compositions are characterized by “breathing” abilities that guarantee the unimpeded passage of vapors from inside the room to the outside.

Processing walls of aerated concrete inside the house begins the same way as outside.Likewise, inspection is carried out, and significant deficiencies are voided. Before filling the surfaces, the aligned wall is primed.

Interior decoration is a special plaster, which includes gypsum and perlite sand.

After performing the work, the walls become homogeneous, smooth, without the slightest visible defects. Plaster consumption is small because the layer is applied very thin. At the same time, there is no need for long leveling, which is also important.

Painting of internal walls should be made with paints specially designed for aerated concrete. They can be applied to the usual plaster and decorative. Painted surfaces look great - decorative trim for a long time retains its original appearance.

When plastering houses from aerated concrete, you must adhere to the established sequence: first the walls inside the house are processed and only then from the street. The optimum moisture regime for porous walls is achieved by holding a certain time after the completion of internal plastering.

The most favorable time for finishing work inside the house is spring. Duration of exposure depends on climatic conditions. As a result, the walls should dry out after the “wet” works so that the humidity is no more than 27%. The indicator will be provided if the exterior finish is carried out at the end of the summer.

Tips and tricks

When the wall of aerated concrete is in the bathroom, and it is planned to lay tile on it, experts advise to act as follows.

First you need to align the wall, make it look like a flat smooth plane. Best alignment is done by plastering, for example, rotband - this is gypsum plaster, sold as a dry powder. It is perfectly suited for interior work on porous walls.

Before working, do not forget to prime the work surface well. After drying, the plaster walls should be treated with a baking waterproofing. Now you can stick the tile. Suitable glue - Ceresit 117.

Properly selected mortar ensures long-term service of the finishing layer. The mixture must have good adhesion, and also have impact resistance.

The temperature of the outside air during work should not be below +6 and above +26 degrees. As for the humidity of the outside air, this figure should strive to 50%.

Experts recommend one year after plastering the facade to apply a hydrophobic solution to the surface - such actions will significantly increase the ability of the walls to resist rain flows and melt water.

You should not save on plaster, because not only the beauty of the visible part of the building depends on it, but also how long the house will last.

To learn how to plaster aerated, see the following video.