Subtleties of plaster facade

Plastering of the facade is a very popular type of decoration of country houses and cottages. In addition to the pronounced aesthetic advantages of wet or monolithic plaster is designed to protect the structure from weathering in the simplest way - by applying a dense protective coating on the exterior walls. However, the facade plaster, like any construction process, has its own subtleties.

Special features

When building a country house or repairing a building according to a design project, the responsibility of choosing a plaster mix for finishing the facade falls on the shoulders of a professional architect-designer. The specialist is able not only to pick up a beautiful color, but also to take into account the peculiarities of the material, in order to maximally emphasize the individuality of the structure and not to exceed the estimate.

Various types of plaster mixtures for exterior work have some similar characteristics, including:

- The ability to create a durable and at the same time "breathable" coating of external walls, under which condensate does not accumulate.

- High elasticity of the compositions, due to which it is possible to apply it on any fantasy wall variants.

- A good indicator of adhesion to various bases (subject to the application technology).

- High resistance to moisture, UV rays, temperature extremes.

- The presence of compounds that perform the function of insulation.

- Excellent decorative qualities.

- Long service life and ease of care.

- Environmental friendliness.

- The ability to quickly apply.

Kinds

Facade plasters can be divided into 4 categories, depending on what substance they are made of. These are the following varieties:

- Mineral, based on the cement mixture.

- Acrylic plaster based on the resin of the same name.

- Silicate, at the base of which are compounds that are called liquid glass.

- Silicone (polymer), made on the basis of synthetic silicone resins.

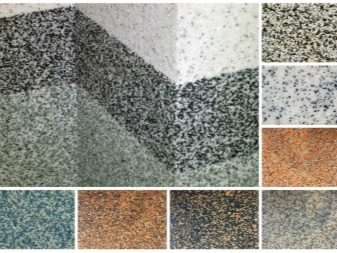

Also distinguish options for mixtures of their decorative qualities. The most famous are “bark beetle”, “fur coat” and “lamb”.Recently, “kameshkovaya” and “mosaic” plasters have become popular, which allow you to create an unusual and even refined design of facades and basements of the foundation.

Modern manufacturers produce decorative plasters on various bases: they contain mineral, silicone or acrylic binders. However, regardless of the type of base, having the common name of the mixture form a similar texture of the coating due to the presence in the composition of the same decorative fillers.

Widely used for decorating facades, terrazitovaya plaster, which is based on a mineral mixture, looks particularly attractive due to the additions of additives such as marble, glass and mica.

The facade is coated with decorative terrazit plaster, reflects and refracts the sun's rays, this visual effect looks very advantageous.

Vermiculite plaster is used on the outside to insulate the walls. The plaster has a bulk filler - vermiculite, due to which the thermal conductivity of the walls covered with this composition decreases markedly.

Application area

A private house, the facade of which the owners want to plaster, can be built of various materials: from monolithic concrete, brick, aerated concrete, wood or stone. For each type of wall, you must select the appropriate type of plaster mix.

There are facade plasters that are applied on top of insulation and perfectly fixed to the mineral wool, foam plastic and polystyrene foam.

Based on the recommendations of manufacturers, indicated on the package, and practical developments of professional builders, we can give the following recommendations:

- On mineral bases (including gypsum plasterboard and mineral wool) silicate plaster will hold well.

- For gas and foam blocks, bricks and concrete, all types of plaster are suitable, however, it is worth considering the fact that some manufacturers, for example, Ceresit, produce a mixture that is most adapted to work on cellular concrete.

- For exterior wooden walls or OSB slabs gypsum compounds are contraindicated. The use of cement-sand mixture is recommended. Also, acrylic facade coating and some varieties of silicone or silicate plaster are used on wood.

- Ventilated facades with insulation can be plastered with silicone, acrylic and silicate compounds, not forgetting the need to use appropriate primers and building mesh, to ensure maximum adhesion with the base.

- Even a metal surface, such as a channel bar, can be plastered, the main thing is to clean and degrease metal well, fix the plaster grid to the surface and be sure to prime it before applying the compound.

Consumption per 1 m2

Works on the decoration of the facade should be divided into 2 stages:

- Align the walls.

- Drawing decorative furnish.

Using facade plaster, an experienced master, when leveling the wall surface, is able to eliminate significant differences and hide small defects. However, in these cases the consumption of the mixture increases, and to calculate the required amount is not an easy task. To facilitate the calculations, it is customary to initially calculate the consumption of plaster mixture per 1 m2. This task is performed by installing beacons. There are several ways to install beacons, but it is most convenient to use steel corners ranging in size from 35 mm to60 mm and plaster rule.

First, the rule with an embedded level determines the deviation of the wall from the vertical. Then prepare the plaster solution, which is applied to the surface of the area. The corner is pressed against the wall and leveled by level, placing the solution under it in the necessary places.

The higher the beacon, the more solution will have to spend on leveling the wall. The next beacon is installed at a distance of 130 cm (in the case when the master is working with a one-and-a-half meter rule).

The vertical between the lighthouses must be checked by level, the rule should not knock on the lighthouses, and there should be no gaps between it and the lighthouses. The more often the beacons are installed, the more accurately it will be possible to calculate the arithmetic average value, and to determine what the mixture consumption should be to equalize 1 square meter. m. When beacons are installed, it is necessary to measure the maximum and minimum layers. The minimum layer starts from 5 mm (the thickness at which the beacon is closed with a solution), the maximum can be quite significant and depends on the curvature of the wall. Between these indicators, the arithmetic average of the thickness of the plaster layer is calculated.

On the packaging of any plaster mixes always indicate the approximate consumption required for applying a 10 mm coating layer. Based on this value, and calculated the required flow for each case. For example, if the average thickness of the plaster layer is 25 mm, then the figure indicated by the manufacturer should be multiplied by a factor of 2.5.

Decorative coating, which is applied over the leveling plaster, most often has a thickness of not more than 10 mm, so its consumption corresponds to the value stated on the packaging.

Application technology

There are several ways of applying facade plaster, for example, one of the very attractive options is to clad a building with decorative trim corners. However, these sophisticated options require the involvement of professionals with experience. For a novice plasterer who wants to do this work with his own hands, such an option as simple decoration of the facade under the “fur coat” is more suitable.

Before applying the decorative finishing plaster mixture, the walls must be leveled.This is usually done using inexpensive mineral plaster, which is sold in a dry form. Preparation consists of the following steps:

- When working with dry mixes, you first need to dilute the composition, for which it is better to use a construction mixer. It must be remembered that when mixing the plaster composition of the dry mixture should be poured into the water, and not vice versa.

- For plastering wooden facades, surfaces with insulation and buildings that are subject to significant shrinkage (for example, new buildings), a facade grid is installed on the surface, which is fastened with screws or nails.

- Then put up beacons that allow you to determine the curvature of the walls. After installation, the beacons are fixed with a solution until completely dry.

- Be sure to carry out priming the surface for the best adhesion with her plaster layer.

- Plaster mortar is thrown onto the wall; this can be done with a trowel, a plastering bucket or a spatula. It is necessary to adhere to the layer thickness recommended by the manufacturer (usually it is 30 mm).

- With the help of plaster rules raise the solution, achieving the most even result.

- While the mass is elastic, defects are corrected and seams are smoothed. These works are performed with a trowel and trowel.

- When the material has strengthened (approximately 4 hours after application), it is necessary to dismantle the beacons, which may subsequently produce rust. To do this, cuts are made on both sides of the beacon with a spatula, after which the strip is carefully removed.

- The shells remaining after the removal of the lighthouses must be sealed. To do this, sweep them with a brush, moisten the surface with water and putty.

- The surface is impregnated with a primer, taking into account the peculiarities of the subsequent decorative composition.

- After applying the plaster, it is necessary to provide comfortable conditions for its drying within 24 hours (the temperature should not be below + 5 ° C, and there should not be a direct hit by water and the scorching rays of the sun).

The execution of a decorative coating, for example, such as a “grated coat”, is carried out only after the leveling layer has completely dried. The time required for this is individual, and depends on the final thickness of the layers.

The work on the decoration of the facade includes the following steps:

- Nakryvka. For applying manual finishing "coat" you can use a brush for sprinkling; for machine finishing, you can use a device such as a pneumogun with a large nozzle and a funnel connected to a compressor. When using a ready-made mortar, it is worth holding the coating procedure 2 times, with pauses allowing the solution to “grab”.

- To perform the coating, known as "Grated fur coat", the surface of the facade wall is polished with a special grater having a steel surface. Grinding movements should be light, only the tips of the surface should be smoothed.

- Calibration to reach the final pattern It is carried out on the dried, but plastic surface. This work is carried out with pressure, the movement must be wavy.

How to put a "coat" on the facade, see the following video.

Tips and tricks

The execution of works on finishing the facade with plaster is a rather laborious process, which requires not only physical strength, but also practical skills. This is the reason for the high cost of such work, and therefore it is natural for home owners to want to try plastering the facade themselves.

Novice plasterers who do not have the experience of this work should experiment on non-critical objects, for example, the walls of the garage, before taking up the decoration of the facade of the building and listen to the recommendations of experts:

- The work on the finishing of the facade is carried out at the final stage of construction, after the installation of the roof, window and door blocks. In order not to stain the windows and doors with a solution, install protective screens.

- External plastering work should not be carried out in the winter, as well as in rainy weather and under the rays of the scorching sun. The optimum temperature is from + 5 ° C to + 35 ° C.

- When working with dry mixes, it is not necessary to prepare at once an too large portion of the solution, since it manages to “grab” within an hour and the unused volume will become unusable. The remnants of the clutched solution must be discarded, there is no sense in diluting them again.

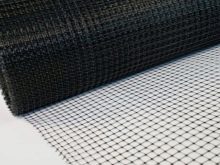

- The metal reinforcing plaster grid should not be confused with a construction chain "chain-link".

- In those cases when there is no significant height difference (less than 20 mm) on the wall, you should not waste time on reinforcement with mesh.

- When the layer thickness is above 50 mm, the use of reinforced fiberglass mesh is required for reinforcement. Application of each subsequent layer is permissible not earlier than 4 hours after the previous one.

- Using a polymer mesh for plaster, you can avoid the danger of oxidation (rust), which is especially important when finishing the facades with a thin layer of mortar. It should be remembered that the polymer mesh is very elastic, so it can stretch when applying the solution, respectively, you need to work as carefully as possible.

- Non-professionals should not use mechanized equipment for spraying.

- You can create an invoice on the surface of the final layer using a special roller or brush.

- Do not neglect the conduct of the primer, which will make the coating more uniform and fix it.

- If, as a result of work, stains, stains and other troubles remain on the wall surface, they can be painted; the dyes based on acrylic or silicone are most practical for tinting facades.

In the event that the finishing is planned on the surface of the insulation (penoplex, foam) - it is not necessary to risk and carry out the work independently. It is better to invite the masters - professionals in their field.