Types and features of plaster for walls

It seems to the average buyer that the plaster for the walls is a concrete type of finishing material. Often ignorance of the classification stops at purchase. In fact, plaster mixes cover a wide range of materials. They differ in composition, appointment, service life. Even a little knowledge from this area will allow you to buy the desired type of raw materials.

Features and Purpose

In the classical sense of plaster - everything that can be plastered on the wall during construction. These are mixtures designed in accordance with the requirements of GOST. Their basis is a binder. In addition to it, various additives are a part. Most of them have a narrow purpose, which explains the wealth of choice.

In each case, provided its own nuances of use and preparation of the base.However, the basic rules for such materials are the same: they are applied to the wall, then leveled.

The purpose of the mixtures is extensive, it depends on the composition of the plaster. Due to it, the mixture can be used for decoration of rooms of unheated type (for example, an attic). Other components do provide for operation in harsh conditions. They withstand temperatures in the winter to -40 degrees. Others are designed specifically for wet rooms where the resistance of finishing materials to critical conditions is necessary. Some are resistant to temperature changes, differing in special structure.

Depending on the composition, they differ in starting and finishing compositions.

Drafts

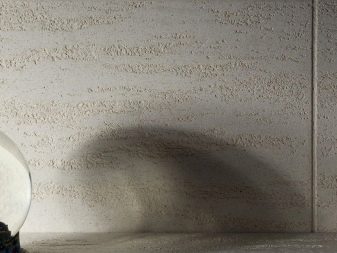

Under rough plaster understand the mixture, which itself is the basis for the finishing material. Usually it trim the surface. Outwardly, it is often unremarkable, its appearance is far from aesthetic. This is a heavy or sandy mass of gray or clay shade.

This category of plaster mixes differs in granularity. Since it is rough, the inclusions are large. Often in this mixture there is sand, which can be seen in bulk.

Such materials are widely used as base preparation. They are appropriate for leveling the surface, masking gouges, chips, seal cracks.

This material works as a dental solution for filling and building teeth. The composition includes a binder that prevents further destruction of the walls. They fill the gap, then trim and grind the surface. The difference is the fact that this plaster needs beautiful material over it. It can be paper (wallpaper), drywall, wall paneling, wood, plastic, glass (mirror), laminate, siding, metal or finishing plaster.

Finishing

Under the finishing material is commonly understood compositions with a decorative purpose. They are not the basis for other finishing materials. This is the main difference between the two types of plaster. They are not used as a rough because of the greater cost. As a rule, the price of such plaster is much higher.

Compositions differ in appearance. Their structure is elastic, elastic, but the grain is much smaller. The grains of sand are not visible, they cannot be felt when rubbing the mass between the fingers.This mixture falls on the surface otherwise. Working with her is nice and easy.

If you follow the basic recommendations of sellers and the rules of the masters, the result is often the subject of pride of the owners.

Apply such compounds with a thin layer. Often, to obtain the best result or a special effect in finishing one material is applied in 2 - 3 layers. Individual varieties cover the walls up to 5 times, mixing different shades in order to obtain a unique appearance. The thickness of the layer in this case should not exceed 1 mm.

To achieve this, the method of applying the mass is chosen automated. It allows speeding up the sprinkling procedure and saves the raw materials used up to 40%.

What's better?

It is impossible to single out one of the species or call it universal for any conditions and needs. For this reason, we cannot say which one is better. If you use the plaster mixture for other purposes, it will not be durable. This usually leads to its peeling from the base, even with high-quality surface preparation and increased adhesion. If the plaster moves away from the wall, you will not be able to correct it imperceptibly.

The base color of the plaster depends on its composition (bases and additives). For example, sometimes the mass has a concrete shade. If it contains clay, the color may be off-white or brownish. Lime gives white color. The mass on the basis of gypsum on drying brightens and becomes bleached sulfur. Decorative mixtures are distinguished by a white tone with varying degrees of purity.

Typically, the brand-manufacturer for the convenience of the buyer supplies its products with a number of recommendations. Marking indicates what type of work the material is intended for (eg, leveling, interior decoration). The type of the recommended surface is also marked on it (for brick, concrete bases, foam blocks, polystyrene finish). Choose the one that corresponds to the specific base and type of work. (external or internal, preparatory or finishing).

Even a process such as plastering a doorway has material requirements. Differs and the solution used when installing glass. One view cannot be replaced by another.: mass will not hold as it should. Sealing solution will not replace the decorative mixture.

Each type is designed to meet the different thickness of the applied layer. It differs in terms and conditions of drying.

The advantages of decorative blends

Finishing mixes used to decorate walls have a number of advantages:

- They are aesthetically appealing. Plaster is an alternative to many finishing materials. The idea of decorating the walls is fresh, therefore it is in demand.

- Mixtures are a quality product. They are performed on modern equipment using new technologies. This increases the performance characteristics of the mixtures.

- Plaster solutions are environmentally friendly. They are safe even for allergy sufferers; during the service they do not emit toxic substances into the air.

- Plaster can have a different color. The composition involves a color change due to the usual color scheme. You can vary the color saturation.

- Most of the solutions being developed absorb noise. This allows you to reduce annoying noise from neighboring apartments or streets.

- Materials are insulation walls. Even a thin layer helps to reduce heat loss, which is noticeable in the cold season.

- PVA glue can be added to any type of plaster.It improves the quality and performance characteristics of the compositions.

- Such materials are base correctors. They are able to level the surface, if it is almost flat.

- Mixtures are variable in the choice of effect. You can choose an option for a specific interior style, pointing to belonging to it.

- Decorative material strengthens the base. The structure is not subject to destruction. Put finishing in the manual and machine way.

- Mixes are durable. With the right technology of application and decoration, they will last more than 10 years without the need for adjustment.

- Materials are resistant to UV light. They do not fade under the sun, whether it is finishing facade materials or solution for interior work.

The composition includes additives that increase the life cycle of the plaster mass. This increases usage time and adjustments if necessary. More mortar can be applied to make the drawing in whole, continuous lines.

In addition, decorative plaster is fireproof. It has unlimited possibilities of imitating different textures.

disadvantages

In addition to the advantages, plaster has disadvantages:

- Not all materials are resistant to condensate. Over time, even cement masses are destroyed.

- Any kind of structure cannot be applied with a thick layer. Time to work increases, non-compliance with the technology leads to cracking of the plaster, the wall can be deformed.

- The consistency of any mixture must be correct. Its modification will cause the deterioration of the appearance of the coating, complicate the application of the composition on the walls.

- Some categories of compounds do not meet the stated requirements. Most often this is due to faking of goods of famous brands.

- Separate blends are washed with each cleaning. Some formulations have to be coated with diluted varnish, others cannot be protected from abrasion.

- Decorative coatings with relief difficult to maintain. Dust sits in the recesses, it is not easy to remove it, sometimes it hurts the skin of the hands.

Types and properties

The range of plaster products covers a wide range of coatings. At the stores you can buy different options - from elastic and flexible to vapor-permeable velvet.

For example, today buyers demand plaster:

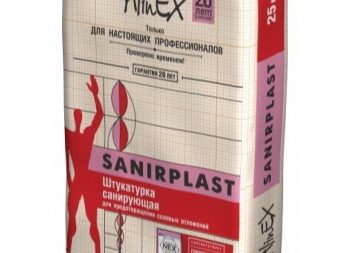

- sanitizing;

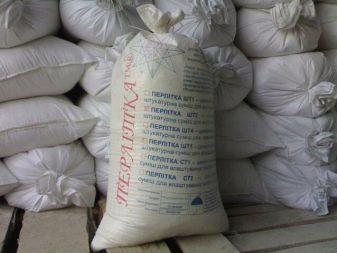

- perlite;

- polymer;

- gypsum perlite;

- cement;

- gypsum;

- magnetic;

- calcareous.

Clay plaster mass is made independently. Today it is rarely used.

Binder mixtures can be acrylic, mineral, silicone and silicate.

Acrylic

Acrylic coatings are characterized by a special elasticity of the applied layer. The basis is a high molecular weight polymer. The origin of the constituent dyes can be organic and inorganic. These are decorative solutions, they are presented in the form of ready-made pasta in buckets on the shelves of stores. The disadvantages are low vapor capacity and instability to ultraviolet rays.

Mineral

The main binder component of mineral solutions is cement. These are compounds that sell in powder form. They have a relatively affordable cost, designed for bathroom walls due to moisture resistance. For the same reason they are used in the decoration of facades.

Such compositions are not afraid of weather factors and seasons. They are considered one of the best environmental materials.They are not subject to fading, but are vulnerable to significant mechanical shocks.

Silicone

Such analogs are based on synthetic resinous substances. This is a simple and easy-to-work finishing material. Depending on the composition, it provides for the use inside and outside the structure and, unlike analogs, repels dust and is resistant to absorption of extraneous odors.

Plaster differs plasticity, in the process of applying creates a moisture-resistant protection, due to what is a suitable material for use in the decoration of wall ceilings for bathrooms, baths, dressing rooms. It is considered a good choice for rooms with a high coefficient of humidity.

This is especially true for apartment buildings with impaired construction technology, including the ventilation system, which is insufficient or completely absent.

Silicate

Such variants differ from the general line of the main component in the form of liquid glass. It is a mixture of alkaline potassium carbonate, silica sand and potassium hydroxide. Along with the water repellency, silicate types of plaster mixtures are characterized by special strength.Such a layer after drying is reliable and resistant to mechanical damage.

This material eliminates the rotting of the material for which it is the base. It is resistant to mold fungi, rather sticky and fire-resistant. On store shelves presented in the form of the finished product with a different color.

Silicate finish in the field of craftsmen is considered one of the best, reliable and durable. It is designed for 30 - 50 years of operation.

Release form

The market of building materials is packed with offers for different tastes and purses. Among the wealth of choice is easy to get confused. All products can be divided into 2 types according to the form of release. This raw material in the form of semi-finished and finished plaster materials.

Dry plaster compositions are presented on the modern market in the form of powder of different types and composition. They are not connected and gypsum fiber sheets. Most often they are sold in standard bags of 25 - 30 kg. Sometimes packing is less (2, 5, 10 kg). Components are balanced in such a way that the mass meets the stated requirements and practicality. To work the raw material is prepared using ordinary water at room temperature.

The amount of water manufacturer indicates on the package itself. Usually on 6 kg of mix 0,2 l of water leave. However, in addition to the basic components, trademarks provide for the combination of components with additives as desired. More often it is the color scheme, since the addition of other inclusions will not be transmitted to the necessary extent. For this reason, certain types of coatings are decorated after they have dried in different ways.

Ready mixes are self-sufficient material for finishing. Unlike dry analogs, this plaster is exclusively finishing or decorative. The release form - plastic buckets of different volume (5, 10 kg and more). It does not need to be diluted, the mass has the desired consistency, resembling a paste. Often it is already painted, which increases its value.

However, the colors of this material often want the best. Only pink, beige or woody materials can be found on the market.. Of course, the finished tone is convenient if you have a lot of work. No need to tint and pick up each portion of the mixture. However, often the buyer wants to decorate the interior of the house with a coating that is not on sale.

An ordinary buyer does not always know that not a single plaster mixes up all at once. Even an experienced master with professional equipment does not use on all walls the composition, whose life cycle is short. Dry mix will be the best solution..

In order not to doubt the fit of the shade, you need to record the number of colors and use the measure for each batch.

The finished mass is often thicker powder analogue. When you open a container, its properties begin to change. Dry varieties also dry out, but their life cycle is somewhat longer. Other factors speak in favor of the powder. Such material is cheaper, it is easy to maintain, and if it is used, excess plaster is practically impossible. This is due to small portions of the mixture.

All types of plaster material can be divided into several categories.

Special

Special plaster coatings include varieties with special fillers. This is a kind of screening insulation layer. One of the varieties of this material is a X-ray protective mixture.

In addition to the basic set of requirements stated in GOST, it has protection against electromagnetic radiation and is distinguished by its inexpensive price. The thickness of the protective coating is usually small. Work needs to be done quickly, as docking in this process is unacceptable..

An interesting variant of plaster mixtures is an acid-resistant variety. It is used mainly on objects where the walls are exposed to aggressive acid fumes (in industrial workshops, laboratories). The basis for such raw materials is a product on liquid glass. The composition includes quartzite and stone flour.

To prevent the glass from collapsing due to exposure to air, another layer of plaster is applied on top of this coating. This is usually a cement-sand based product. followed by ironing.

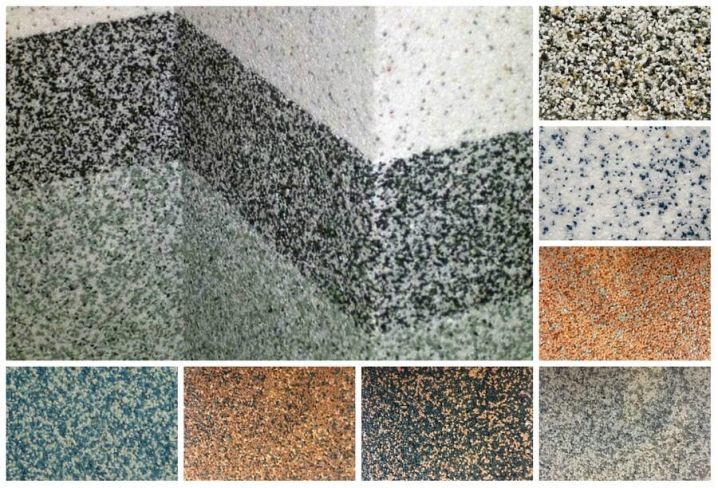

Decorative

One of the best plaster mixes is included in this category. These are special blends with the best decorative features. Such plaster can be finished or powder. In the second case, the master has the ability to implement design ideas. Particularly advanced finishers sometimes make unusual types of plaster material from classic putty.

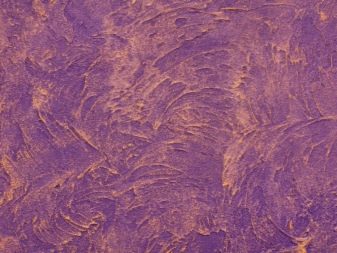

To the ordinary buyer, trademarks offer to ease the work. Pearl, Italian, Viennese and French plasters can be found on sale.Noteworthy roller texture, latex-plastic, wet silk. Each mass is different in color, effect and method of application.

For example, in order to transfer Versailles plaster correctly, it is sprayed with silverfish after drying. Venetian is applied in several thin layers. When applying each layer alternate tiny portions of plaster mass with stretching them into each other.

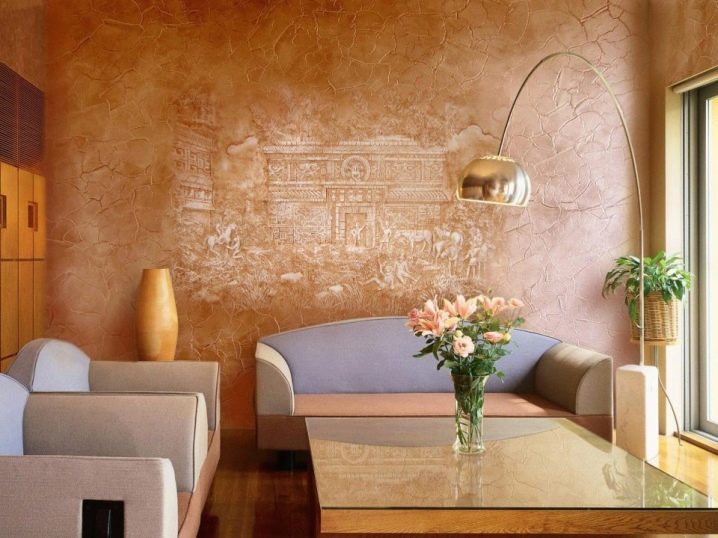

One of the trendy designs is the craquelure technique. (effect of cracks with a flash of the fundamental tone). "Bark Beetle" transmits the texture of wood, sharpened beetle. "Fur coat" obtained by rolling a pile roller on the fresh surface of the plaster.

You can use different techniques to make the texture. Rollers wrapped in cellophane, crumpled newspaper, nails, fingers, special plastic trowels and trowels are appropriate. The best decoration of such surfaces is stucco plaster over the lining.

Facade

This category includes compositions for exterior wall finishing. They differ from internal analogs in resistance to the effects of all weather factors. As a rule, their structure is not destroyed by frost, gusts of wind, precipitation, or ultraviolet radiation. These are particularly durable types of plaster material.Their main criterion for demand is durability.

However, these types of material are particularly demanding on the choice of base. Options for cellular and lightweight bricks will not withstand heavy compositions. It is impossible for them to even out such a base, because cement-sand or cement-lime masses can cause the deformation of such coatings. Externally, the plaster coating will begin to tear away from the base, covered with cracks.

Acoustic

Acoustic plaster called a special mixture, the task of which is to reduce noise. Previously, such material was used primarily in the decoration of industrial workshops, as well as cinemas and concert halls. Today this raw material is irreplaceable in cases of curvilinear architectural forms. They replace fully acoustic systems where they cannot be made due to the structural features of the structure.

These varieties are applicable for the decoration of rooms with echoes. Usually it is the decoration of the walls in rooms with floor tiles or marble. Such variants differ from the basic composition by the inclusion of pumice, expanded clay, slag, perlite or vermiculite.The density of the mass with an acoustic effect varies between 500 and 1300 kg / m.

However, it is undesirable to paint or whitewash such plaster: this reduces the level of sound insulation.

Heatproof

Such plaster options prevent heat loss. They isolate the room or communication. The composition may include granulated polystyrene foam, hydromica or perlite, which is a mineral of volcanic origin. These varieties in the language of the builders are called warm.

A characteristic feature of such compositions is a small weight with a significant amount. The heat-shielding plaster itself is light, it is capable of supporting the necessary microclimate inside the premises. Due to this, the need for additional warming of the facade surfaces with mineral wool or polystyrene foam is often not necessary. The texture of the material is pleasant in work.

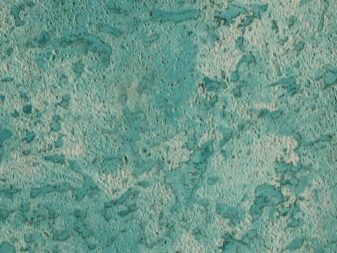

Waterproofing

Waterproofing plaster mix - material based on waterproof polymers. Such options are used to protect buildings from moisture and steam. They are relevant in the decoration of bathrooms, combined bathrooms, balconies. In addition, waterproofing waterproofingcomes to work in the basement, insulating the walls of pools, baths and saunas from moisture.

Apply this material where the plastered surface is subjected to hydraulic loads from constant contact with water. Binder of such plaster are resins based on polyurethane or acrylic, as well as epoxy analogues.

An interesting method of enhancing adhesion and enhancing water repellency during surface treatment is the application method. Such solutions are applied by means of a thin-gun.

The difference in quality: where is it used?

According to the technological map, the plaster can be made in 3 variants, which explain its quality characteristics. On this depends on the method of application.

Work with plaster masters divided into 3 stages:

- sprayed (base layer under the plaster);

- priming (trimming layer);

- nakryvka (topcoat).

Simple

Such a solution can be applied in 1 layer with grinding or without it in non-residential premises. There is no need for covering. Additional layers are not needed: the coating is ground immediately after applying the mass. To do this, use a plastic grater.The process is far from simply smearing the material on the wall.

Cement-lime mixture stretch without beacons, align the rule. The maximum thickness of the layer can be up to 2 cm. The texture of such compositions can be rough, but necessarily smooth.

Improved

This mass is applied in 3 layers (sprinkling, primer and coating), applying in residential and non-residential premises. The consistency of the first is more liquid, so it is necessary to enhance adhesion. Wherein layer thickness should not exceed 0.5 cm.

The main load is created on the soil layer. Its thickness can reach 1 cm, but not more: you need to leave it for the third layer.

If you initially plan a thick layer, do not do without a reinforcing mesh. Suitable composition based on gypsum, lime.

High quality

This type differs from the previous ones by the identity of all layers. It is characterized by the accuracy of the work. This is a polymer mixture with the installation of beacons. In the classical method of work they are fixed by level and cord, achieving vertical and horizontal accuracy. This is the best variety for interior wall decoration.

The technology includes 3 stages (spray, primer and coating).Usually for such work do not use lime-based formulations. Grinding is carried out with a metal spatula or trowel.

The main difference from all types is the size of permissible deviations in quality control.

Instruments

Work with plaster provides for a certain inventory. In each case, it can vary, depending on the type of material used.

The basic kit includes:

- mixing bowl;

- construction mixer with a special nozzle;

- packagings;

- tool for splashing (hopper, spray gun);

- trowel or trowel;

- the rule;

- guides;

- trowel;

- level;

- roulette;

- tool for forming a pattern.

In addition, you may need beacons, grinders or metal shears, a Phillips screwdriver, drills, a hammer and a hammer drill.

Application

You can use the plaster in the construction and decoration of buildings of any type. Its use is appropriate for work in multi-unit and private (suburban and suburban) houses. To understand what kind of mass is needed, it is worth starting from the conditions in which the material is planned to be used.

It is useful for industrial facilities, new buildings, as well as public buildings:

- clinics, hospitals;

- pools, baths, saunas;

- administrative agencies;

- hotels, clubs, cafes;

- cinemas, studios;

- educational centers;

- sports halls;

- educational institutions (kindergartens, schools, institutes).

On the market, such products have their own classification. To save time on the study of the range, it is necessary to determine in advance the type of surface and select the desired material. Sellers will always tell you which vapor impermeable mixture is better, explain the subtleties of products with sawdust, the differences in graininess. They will certainly focus on the best qualities of the product, especially if the plaster is refractory, cork, X-ray protective or bulk.

Almost always note the special properties of the finished mixture and its special effect. Such material gives a lot of opportunities for design. It is comparable to the canvas, on which you can convey the inner world through curly lines or paintings through the material of different shades. The basis for images is a smooth type of trimmed surface. This is a finishing finish.

Decorating walls with plaster will be durable, if you choose it according to the type of base. In some cases, it must be vapor-permeable, and sometimes vice versa, vapor-tight.

Brick

Depending on the type of work (internal or external), plaster walls of brick need different materials. The correct type of raw materials are cement-sand based mixtures.. Indoors, you can use a kind of mixed with lime.

Maximum permissible layer thickness is 3 cm. Under the plaster it is necessary to fix the netting-netting. Due to it, the solution will be better kept on the surface.

When adding lime it is necessary to take not the dry component, but lime mortar. Finishing facing bricks is a little more difficult. Here the usual chain-link is not always effective, therefore it is necessary to select the reinforcing mesh very carefully. Besides, you need to prime the surface before applying the solution.

The main composition of the mixture - sand, cement, lime paste and water for dilution.

Concrete

The surface of the concrete base may be smooth or rough. In the first case, in order to enhance adhesion, it is necessary to treat it with a primer with quartz chips. Cement based mixture with gypsum is used as plaster. Its inclusion enhances adhesion.

For interior decoration, you can use the composition of 3-4 parts of lime and 1 part of gypsumby stirring it with lime fluid.

If the walls are rough, there is no need for complex preparation. On them, the plaster will fall well and it will be better to hold. For the decoration of the walls outside it is better to use cement varieties. It is possible to process wall ceilings inside with plaster material.

To enhance the adhesion and to give the structure uniformity of the wall before plaster, it is better to treat it with a primer with high penetrating power (“Betonokontakt”).

Tree

The wooden house needs special attention when finishing walls. The mass should protect the wood from rotting, mold. In addition, it must resist the effects of rodents and termites. Plastering of the house from a bar can be carried out a year after construction. We need to wait for the end of the shrinkage process. Facade plaster is usually carried out with lime-cement composition.

Besides, apply compositions with clay. Of all the varieties, it is more suitable for conditions of high humidity, compatible with any temperature conditions of the region.Partitions finish mainly lime-plaster composition. Gypsum analogue is suitable only for interior decoration.. It can not be called the best, with high humidity, it exfoliates from the base.

To enhance the decorative effect, after drying, the plastered surface is treated with CMC-glue or wax mastic.

GVL

Plastering of gypsum-fiber sheets is necessary for sealing and leveling the inter-tile joints. It allows you to enhance the adhesion of the base GVL applied to them finishing materials. It is also necessary to level the absorbent capacity of drywall. For this use dry plaster mixes on a plaster and polymeric base and ready-made analogues from polymers.

The fraction of filler grains may be different. It depends on the type of filler used. A layer can fill only a microrelief or it is used as a starting leveling agent. Tightening putty carried out so that the seam was almost imperceptible. Usually the thickness of the layer does not exceed 1 mm.

The life cycle of the material is limited, so you need to apply plaster quickly.

Under wallpaper, painting, tile

Finishing materials are used for preparing the base for further finishing. Plaster for painting should be small fraction. These are compounds based on gypsum or polymers. In fact, it is the basis in the form of bulk plaster, which is painted. This decorative technique looks unusual, but allows you to update the background of the wall floors and mask the correction if you have to disassemble the damaged area.

Typically, water-based paint is used for such coatings. Paint the dried wall with a roller, rolling it over the entire area. If you want to give the painted surface a light touch of vintage, the protruding points are sprayed with a sponge with silverfish.

Variants for wallpaper - plaster compositions with a pleasant texture. They allow you to perform a fine finish. In rare cases, its thickness reaches 5 mm.

If the percentage of humidity in the room is high, cement mortar must be used instead of gypsum-based materials.

He is not afraid of moisture and moisture, is a versatile rover walls. However, if the fractions in its composition are large, after such a plaster it is necessary to use putty (for example, oil or acrylic).

Under the tile using classic cement mortars in bags.A simple man in the street easier to recognize them by the mark "glue for the tiles." Externally, it is a gray bulk mass that needs to be diluted with water. The grain size of the mixture depends on the sand. The consistency is selected by the specified marking. The composition should not drain off the walls.

In order to avoid rejection of the material from the walls, the formation of cracks, the masters add glue to it.

On other surfaces

In addition to traditional materials, to date, buy plaster for finishing walls from:

- aerated concrete;

- foam concrete;

- penoplex;

- polystyrene foam;

- OSB-plates;

- gas silicate blocks.

Rarely it is used for finishing adobe walls. Pazogrebnevye blocks, of which the structure was built, no need to plaster. It is believed that for them enough putty, and the surface and so smooth, smooth. Other options are more suitable for accenting small areas than monolithic coatings on the perimeter. The plaster under the penoplex should be light.

Color mix is made on an acrylic basis with an addition of a marble crumb. It is good for finishing mineral surfaces. Differs in water-repellent properties and hardness of the structure.The range has about 15 different shades, including beige, coral, terracotta, pink, mustard and turquoise. Such material is intended for internal and external works. Apply it only on a dry base with a thin layer.

For the decoration of the walls of the facade is good roller mixture of natural origin.. Here you can use the DSP (for example, when working with siding). Views on the basis of cement and sand are good for eliminating obvious potholes and chipping, curved walls in the premises of a private or multi-family house.

Suitable for different types of material latex plastic. It is used for interior decoration of traditional materials of floors (concrete, brick, wood), as well as drywall, aerated concrete, foam blocks. This material is resistant to deformation. Due to its elasticity, it does not crack, it differs in the texture of marble.

Metal - not the best type of substrate for plaster. If the question of application is fundamental, do not do without welding the mesh of the chain-link. So plaster will hold on better. Other ways of working are ineffective. Using a primer will not save the surface from cracking and peeling from the metal substrate.

The clay walls are plastered outside with lime mortar.. Cement options are not suitable here.They will crumble due to their severity. Interior finishing can be done by means of plaster mix. Clay may have a white, red, gray and yellow color. The reinforcing component of the mixture are sawdust. Due to them, the composition becomes more reliable.

Dressing

Decorative techniques when working with plaster are different. This is not a simple smearing on the wall, but an imparting of volume, relief, a way of making the decoration unique. Many types of raw materials provide decoration, but everywhere it is different. In one case, this is the initial execution of the pattern with the help of a special tool, in the other - alternating alternation of layers of different colors. Sometimes and at all mass is painted after giving the surface of the pattern.

Each method depends on the creative capabilities of the master and skills of working with similar masses. Sometimes the surface is trimmed by grinding after each applied layer. In another case, it is important to leave the relief intact. Some types of coatings have to be varnished, diluted in half with water. Use it in its pure form is impossible. From this, the surface loses its status view.

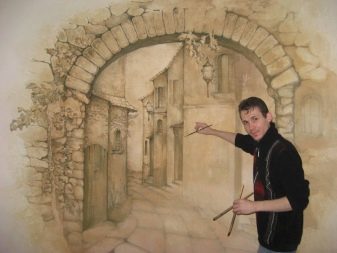

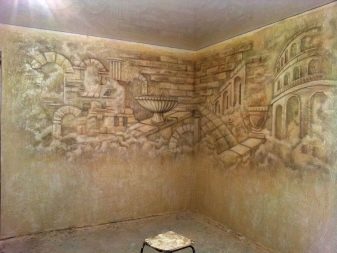

The best decoration technique is plaster painting.. Externally, this drawing is on par with the main background. Only masters with artistic skills are able to do this. In the interior of rooms such paintings look like inserts opening the veil into the past. Their creation is a difficult process.

The master selects several tones of the same color that differ in the degree of saturation. Subject can be any. but more often, designers prefer fragments of being of old historical eras. These are dilapidated cities, sculptures.

An unusual type of decoration is the creation of relief. To do this, use several methods. If you need an identical pattern, use stencils or anti-patterns. When the master has the skills of sculpture, he creates masterpieces with the help of a small trowel, gaining weight on it and distributing it on the finished and dried finish.

This technique allows you to get a three-dimensional effect with the theme of floral motifs and antique sculptures.

Do I need training?

The answer is unequivocal - yes. Whatever composition is planned to use, it is preparation that enhances its operational properties.This is not the advertising course of trademarks in order to purchase excess raw materials. Modern materials will strengthen the base, to make its structure homogeneous.

The process consists of several stages:

- inspection of the base;

- removing the old coating;

- removal of hillocks;

- priming;

- masking gaps, chips, holes.

Inspection shows the amount of upcoming work, the number and type of necessary raw materials, the choice of inventory. The old coating must be removed, because it can move away from the base.. If the inspection found fat spots, they should be eliminated. No type of plaster will hold onto them. Dirt and rust must be removed.

The primer not only strengthens the walls. If you choose the right type of material, it will become the link that holds the mass for many years. Masters have repeatedly noticed that its use seems to attract the solution. It does not flow and is not smeared in the process. In addition, due to the primer decreases the absorption of the walls.

This affects the drying time of the plaster. The wizard has additional minutes to adjust or execute the pattern. This way you can reduce the number of visible joints with a lack of experience.. However, until the primer is completely dry, it is impossible to apply the mass to the walls.

After plastering, a primer is applied only if it is rough (for example, under wallpaper).

Manufacturers

In the modern construction market, a wide list of plastering materials is presented to the attention of the buyer. Trademarks often focus on certain types of material, not covering the entire spectrum. This allows you to improve product quality, its demand among buyers and the high appreciation of professionals in the field of construction.

The rating of popular companies includes:

- Knauf;

- Vetonit;

- Ceresit;

- Bergauf;

- Unis;

- VGT;

- "Miners";

- "Reference".

Each produced material is different from the analogue of another manufacturer. Masters include the three leaders of the company Knauf, Ceresit and Unis. Their range is not satisfactory. The company's products "miners" marked including negative customer reviews.

The reasons for the negative comments about the different types of plaster mixes left on construction forums are rooted in the presence of fake products. Masters say that even in large retail outlets you can buy a fake.Packaging is sometimes done on a professional level, which does not give doubt to the counterfeit goods.

However, there is a way out: you need a certificate of quality and compliance with generally accepted standards.

To the quality of a fake does not become a cause of marriage, you must first browse the information on the World Wide Web. You can visit the manufacturer's official website and ask online about its official suppliers. Usually companies give the buyer comprehensive information. In addition, you can always study the reviews of buyers and craftsmen.

Place in the interior

Plaster materials today are changing stereotypes. They are the focus of designers, recognized as a unique finish, appropriate in different rooms of the home. With their help, you can add zest to any branch of stylistics. They are harmonious in the decoration of classical trends, are relevant in the decoration of modern, ethnic and vintage movements, are popular in creative design.

Belonging to a specific style is transmitted through texture and color. For ecological interior compositions, this is naturalness, demonstration of wood texture.. For example, you can finish in the technique of bark beetle.

Classic is important to show luxury, coupled with gold. Layering is not needed here: the main focus in such areas is furniture. However, the imitation of stucco as a selection of one of the functional areas is quite possible.

Vintage directions illustrate the Venetian and Versailles varieties. In the first case, the surface is smooth, in texture resembles marble.

Versailles has a small relief. Light silver plating followed by varnishing makes the background wall decoration special. Modern style prefers glossing.

The facade needs simplicity and some roughness. Its typical representative is textured plaster under a fur coat. Looks good and "lamb". The same rules are appropriate for non-ordinary decisions (for example, loft, grunge). No need to level the surface to smoothness.

These styles need finishing for concrete, lime with a rough texture. This plaster looks great on the background of brick or masonry. The main thing is to transfer the atmosphere of an industrial facility with a separate inhabited island.

The rougher the cover, the better. You can finish the column, ledge, partition, a small part of the wall or one plane.

Beautiful examples

In conclusion, you can take a closer look at the examples of plaster wall decoration. Design techniques for different rooms of an apartment or house convey a different emotional perception.

- The living room in fresh colors looks stylish. Unusual muted color harmoniously with the color of curtains and furniture.

- Accent wall recreation area. The use of sand color and coarse texture is smoothed due to the white tone of the ceiling and partition.

- Highlighting the walls in front of the entrance to the kitchen. Relief texture makes a special mood in the space, perfectly combined with the brevity of the overall design.

- Design with elements of glossing reveal the possibilities of Venetian plaster. The combination of pearl-colored walls with beige-tone furniture is in the spotlight today.

- Acceptance of the use of plaster with imitation stone to highlight the guest space. Against the background of the glossy texture of the floor, the coating looks especially expressive.

- Design in the studio layout. Use matte light gray tint texture for one of the walls.Emphasizing the guest area.

- Craquelure technique along with artistic sketches made of plaster to match the base. A good choice of the color of the material is revealed against the background of bright living room furniture.

- Plaster with imitation brickwork looks impressive. It will radically change the attitude to this material. The decoration is impressive against the background of a complex ceiling design.

On how to implement the plaster walls of the beacons, see the following video.