Choosing a plaster mixture for outdoor work

The decoration of the facade of the building is a work, the quality of which determines the external attractiveness of the building, as well as its durability. Today there is a mass of building materials for solving such problems, among them it is worth to highlight the plaster mix, presented in a large assortment.

Special features

It is the plastering of facades that is considered the most common and time-tested method of exterior decoration of houses. Plaster is a universal construction products, whose features allow the structure to provide a complete look, while hiding possible defects or errors on the surface.

Plaster mixtures for exterior decoration must meet two basic requirements for the material: to be durable and have a long operational life.

Among all the characteristics inherent in the material, it is the density indicator of the composition that will play a huge role, since the quality of the mixture largely depends on it. Most often, this characteristic is prescribed by manufacturers of dry plaster on the packaging.

The mixture can be used as a finishing coating for the facade, in this embodiment, the product is produced using special technologies, they allow you to end up with an original and attractive facade of the building, which will not need additional finishing. However, it is not uncommon for the mixture to be used for processing walls with the use of other finishing materials for the final work on decorating the foundations of the structure from the outside.

Plaster consists of the main ingredient, which acts as a binder, and filler - it can be sand, gypsum, lime, cement, and so on. The composition of the plaster allows you to classify the material of this line of building products.

Products for internal and external work allows to level the base, provides protection to the base from cracks, has a positive effect on the microclimate. In addition, the products are used for sound insulation and thermal protection of walls.

The mixture can be prepared with your own hands or purchased in constructionsupermarkets or markets, but the quality of the solution, prepared independently, may not meet expectations.

Products that are offered by manufacturers of plaster mixtures are made in accordance with GOST, so its acquisition will allow you to perform high-quality and therefore durable finish.

It is necessary to highlight the main positive features of the plaster:

- thanks to the application of the material on the walls, a flat surface is formed, which will help to hide construction defects, if any;

- plaster provides moisture protection, acting as a barrier against the destruction of walls by dampness and moisture, which is important for outdoor bases that interact with the environment;

- a layer of applied material has a good level of vapor permeability, so that the walls can "breathe";

- the products can be used for finishing of any bases - brickwork, concrete, and there are also mixtures with which walls insulated with mineral wool and foam plastic are processed;

- thanks to some types of mixtures on the facade of the building, you can create a variety of textured surfaces, realizing the most courageous desires of the owners of the house;

- according to many experts, the use of this product will cost much less in comparison with other materials for exterior decoration;

- The composition has a good level of maintainability.

In addition to the advantages of the material, it is worth highlighting some of the disadvantages of plaster:

- due to the complexity of the process of applying the work with the composition requires a certain qualification and experience;

- Application of the mixture should be carried out under good weather conditions, excluding any precipitation, since high humidity will adversely affect its contact with the base, which is fraught with delamination of the applied material.

Kinds

Today, the market has a large number of different plaster mixes. They are divided into types, taking into account the binding component that is included in the composition, as well as the type of treatment for which it is planned to use the product.

The following types of mixtures can be distinguished:

- ordinary;

- decorative;

- special purpose.

The compositions belonging to the first group are used to impart a flat surface to the base as a preparatory layer. Mixtures can be processed walls made of cinder blocks, bricks, concrete and so on.

Plaster reliably protects the surface from the effects of external factors. As a rule, in the future, ordinary lacquer is applied with varnish, paint or other finishing compound. Different plaster mixes belong to this production.

- Gypsum plaster - for outdoor work it is purchased less frequently. However, the material has a high level of adhesion to most surfaces, it is characterized by low thermal conductivity, and after drying, the composition does not crack. The disadvantage of plaster is its low level of resistance to atmospheric phenomena, due to which the mixture is more in demand for use as a product for interior wall cladding.

- Cement-sand composition - the most demanded material for the primary processing of the facade. The main components of the products are sand and cement. The main positive qualities of the composition should be considered versatility and strength, due to which it is preferred to use it to level the bases. In addition, the mixture has a high level of moisture resistance, and also tolerates negative temperatures.

- Cement-lime mixture consists of the same ingredients as the previous composition, and this list is supplemented with lime, thanks to which the material acquires good plasticity. This at times facilitates the application process.

Textured plaster for external works is applied at the final stage, connected with the finishing of the facade of the building. Materials of this group are distinguished by a large variety of colors and texture of the bases, which are obtained during the application of the composition.

This product category includes various types of mixtures:

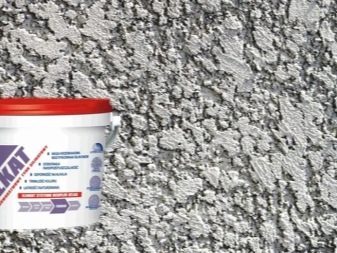

- Mineral plaster - popular products for finishing works with a facade. Its demand is due to the affordable cost, as well as versatility, so that it is allowed for use on most surfaces. The composition of the plaster includes mineral components and various additives. Among the products related to the mineral composition, we can distinguish the decorative composition "bark beetle". After its application, a layer resembling a cut of a tree damaged by a bug is formed on the surface.

- Acrylic products - it has a long service life, which can reach 25 years.Acrylic resins are present in the composition of the plaster, thanks to which you can hide even the smallest cracks present on the base. Technical characteristics, in particular, plasticity, mixtures allow plaster to stretch well when applied, which eliminates shrinkage and cracking of the layer. It is necessary to attribute its vapor impermeability to the disadvantages of an acrylic composition; therefore, it cannot be called a universal product. Manufacturers recommend processing only foam with an acrylic composition.

- Silicate composition - due to the main component, which acts as potassium liquid glass, the products can be attributed to particularly durable mixtures for outdoor work. In contrast to the previous type of plaster, the silicate mixture has a good level of vapor permeability, due to which it should be used for works with a facade, where insulation works were carried out using basalt wool. The plasticity of the composition does not allow it to crack, and the anti-static qualities do not allow dust to accumulate on the facade, which favorably affects the external attractiveness of the building.

- Silicone plaster mix has the highest cost, the products are already ready for application. Due to good adhesion to most surfaces, plaster is used as a repair compound for the restoration of old structures. Stucco elastic, the market is represented in a diverse color palette. The disadvantages of products should be attributed to the fact that it can only be used with building compounds, which belong to the silicone group, in order to preserve the adhesive properties and good adhesion of materials.

- Polymer blend - pretty new product in the construction market. With the help of such a composition, the facades and the basement of buildings are finished. The technology of applying products does not require a large layer thickness, so its consumption per 1 m2 will be minimal. Products provide the surface with a high level of resistance to freezing temperatures, as well as resistance to mechanical damage.

The choice of special plaster mixes for facades is based on the desired effect. Compounds may be needed to provide protection from moisture, freezing temperatures, or external noise. Besides,This product acts as a base for the subsequent application of an invoice mix.

It is necessary to distinguish the following types of material on the basis of functional tasks:

- X-ray protection products;

- waterproof formulations;

- soundproofing mixtures.

Manufacturers

On sale you can find products of various domestic and foreign manufacturers.

The list of the most popular brands should highlight products. Knauf and Kreisel. The range of products includes plaster mixes for exterior decoration, cement compositions, mortar materials for hand and machine application.

Domestic products "Miners" in demand on a par with German counterparts. In the list of materials from this company you can find a popular series. "Bark Beetle", as well as cement plasters. Among domestic companies, it is also worth highlighting the products Founded, Rusean and Volma.

Henkel Bautechnik offers formulations CeresitBecause of their high quality, they have been popular for quite a long time. Among the proposed materials is to provide products Ceresit ct 85 and Ceresit ct 35which work outdoors and indoors.

Tips and tricks

During the selection of a composition for the facade, one should base his choice primarily on the individual characteristics of the material from which the walls of the building are made. In addition, important factors are the technical and operational properties of the material, which will determine the calculation and rate of the required amount of composition for application, visual appeal and durability of the lining.

For buildings whose walls are insulated with expanded polystyrene, ordinary plaster composition will not work. With such material it is necessary to work with the help of a specialized solution that can provide reliable protection from ultraviolet radiation and temperature drops.

Since aerated concrete blocks are characterized by a high level of hygroscopicity, the material will need some protection - a plaster mix for aerated concrete. You can use the tool that forms the usual surface, and you can give preference to textured facade mix.

Regardless of the type of composition chosen, Before work, the surface must be pre-cleaned of paint and dirt and degreased. Window openings are best protected against splashing from the composition. Plastering of the frozen base is prohibited.

On the features of the facade plaster Terracoat, see below.