Brick plaster: types and features of application

A wide variety of materials for interior and exterior decoration is presented on the construction market. Among them, a special place is occupied by plaster, through the use of which you can create an imitation of cladding of the facade or walls inside the building of various kinds of textured elements, for example, finishing surfaces under a brick.

Special features

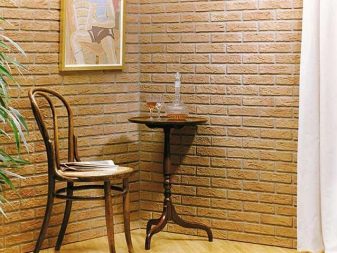

Decorative plaster gives the base a relief texture, due to which the surface acquires excellent aesthetic and operational features. Laying bricks has become a familiar and effective solution for decorating walls in rooms for various purposes. In the interior, a brick wall acquired a slightly different meaning than before, now this is not an indicator of homeowners ’poverty, but a creative and modern veneer option. That is why most of the famous designers use brick plaster for interior decoration of modern offices, apartments and country cottages with the aim of placing accents in the interior, emphasizing the chosen stylistic direction.

In addition to the popularity of this material in terms of aesthetic purpose, plaster ensures the preservation of the previous size of the living space, without piling up space, and also represents an environmentally friendly solution for tiling, regardless of the type of mixture that will be used during wall plastering.

From the point of view of the characteristics relevant to the consumer, textured plaster, imitating brick laying, has some advantages and disadvantages. Among them are several points:

- The simplicity of the work, due to which there is no need to involve specialists in the task.

- Affordable cost of the material - the price of plaster is almost on par with the cost of wallpaper. In particular, in the case when as a mixture, putty will be used.

- The finished surface or the solution itself can be painted in any color and shade you like, and also give it the most intricate shape.

- Due to the surface treatment of the walls with plaster, a special additional layer is formed on the base, the presence of which increases the soundproofing and heat-insulating properties of the whole structure.

- Among the variety of wall finishing products on the modern construction market, plaster creating imitation brickwork is an environmentally safe material that does not form hazardous volatile compounds released during operation.

- The long service life of the finish is ensured by such qualitative characteristics as resistance to abrasion and mechanical stress. The presence of these properties of the mixture makes it possible to successfully apply it in rooms with a high passing capacity, for example, in the kitchen or hallway of the dwelling.

- The finished surface can be repainted over time, eliminating the need for major repairs after several years.

- The weight of the coating is several times less than the mass of the base, lined with decorative brick.

- Minimum time to complete the walls.

- Coating resistance to moisture and heat.

- Thanks to well-applied plaster on the wall, you can get a full 3D effect.

- The universality of the material, based on the possibility of a harmonious combination of a similar finished surface with any style in the interior.

- Brick plaster is a reliable and unpretentious material to maintain.

The disadvantages of such a facing include a high level of static of the finished surface, due to which dirt and dust collect very quickly on it, especially in the slots.

In addition, in order to finish it well, a preliminary treatment of the working base is necessary.

Kinds

There are several options for plaster mix, with which you can finish both outside and inside the room:

- cement-sand mortar;

- lime-sand mixture;

- clay based mortar;

- gypsum plaster.

Each type of material allows the inclusion of additional components in the basic composition, for example, plasticizers, additives, or coloring pigments.Substances allow to increase the resistance of the coating to adverse atmospheric conditions. Most manufacturers regularly update the range of products presented., producing ready-made dry mixes for lining, which have various properties and characteristics.

This trend has a positive effect on customer demand, since, having read the enclosed product instructions, you can easily select the desired composition that will meet all the requirements in a given situation.

Therefore, anyone can do plastering of the bases, having minimal construction experience, regardless of the type of working material made of plaster or any other mixture.

Style and design

You can finish the room with plaster, imitating brickwork, you can use all sorts of options - to decorate all the bases or to combine with other materials - tiles, wallpaper, painted surfaces and so on. However, the most popular will be the individual design techniques in the design using this material:

- Facing openings - This applies to areas near the window and door structures, arches, niches, the attractiveness of which will increase several times due to the use of a similar design technique. This option will allow you to select these objects in the overall design of the room. However, by finishing the window slopes, it is possible to increase the resistance of such surfaces to mechanical stress.

- Placement on the walls elements with bricks in a chaotic order. Thus, you can make a kind of picture frame on the wall or mirror panels, fireplaces or any other objects in the room.

- Full wall finish only in the room - this option is considered the most common.

Necessary tools and mixes

Performing any construction work is impossible without a specific list of tools. For the application of textured plaster will need the following devices:

- dry and clean mixture dilution tank;

- masking tape;

- several spatulas of different sizes;

- rule and cord;

- brush or roller;

- drill with a whisk;

- tool for jointing.

In order for the textured surface to be distinguished by its aesthetic appeal and long service life, experts recommend using such materials during the work:

- plaster mix;

- surface priming products;

- coloring compounds or pigments.

Preparatory work

Putting plaster under the brick, in addition to having a certain list of materials and equipment, requires the preparation of the base itself to work.

Surface preparation will make it possible to eliminate the risk of cracking material on the wall during operation. For this you need to perform a number of the following activities:

- if on the basis there are any old materials for finishing - wallpaper or tile, they must be removed;

- with a surface on which there are cracks, chips or other defects, it is necessary to carry out restoration work;

- plaster problem areas on the wall.

How to dilute and apply?

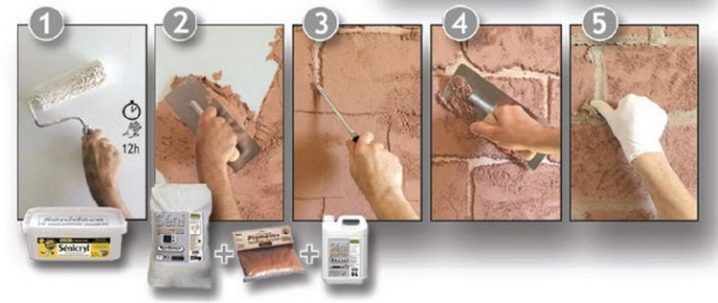

The technology of creation on the selected surface or a separate section of the wall of imitation bricks requires the work to be performed according to the established scheme, guided by the recommendations of specialists. Therefore, in the first place, it is necessary to carry out the work only after all the preparatory stages have been completed, including various processes that required application of different compositions to the base. Before starting work with plaster, the treated wall must be already dry.

Cement-sand mortar is mixed at the rate of 1/3. Mix on the basis of lime to prepare in a proportion 1/4. Clay plaster includes 1 part lime dough, 0.25 clay and three parts sand. Gypsum solution consists of 1 part of gypsum, 0.6 clay and 3 parts of sand.

Ready-to-work solution should be similar in thickness to the cream and not drain from the trowel. It is necessary to take into account the peculiarity of some solutions to harden very quickly - approximately 30 minutes after dilution. On this basis, the mixture should be stirred only before application and in a small amount.

The dry ingredients are immersed in water in batches, well mixing the composition. Breeding in the reverse order - pouring water mixtures that are already in the bucket - is prohibited.

You should not neglect the primer surface, because applying this compound will increase the bonding of materials and reduce the risk of occurrence and development based on harmful bacteria. Priming should be done with a roller and brush.

Marking "brickwork" - an important stage in the work. It should be done in pencil, highlighting the boundaries and contours of each element.To create a decor that will visually resemble a brick as much as possible, the dimensions of the parts and the seams should be equal to natural.

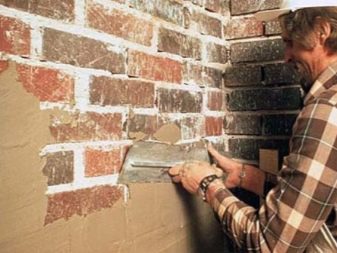

With a plaster with or without pigment, only a clean and dry wall is treated. The mixture is poured onto the base with a spatula and leveled with rules. This brick is rarely the correct form, so you should not level the solution to a perfectly smooth appearance. Acceptable thickness varies in the range of 0.5-2 cm.

Next, you need to create an imitation of the seams with a spatula, knitting needles or any other suitable object, guided by the markup. For smooth lines, use the rule.

Excess mixtures that will be formed during the work on the basis must be removed from the wall with a cloth. It is necessary to do this at the moment when the solution is still not completely frozen.

After the final drying of the mixture, you need to remove the masking tape and perform the final correction of the textured surface, sandpaper or other abrasive material is used for these works.

There are options for the formation of bricks using a roller, a special matrix or templates.The process of working with plaster does not include special complex technological steps, and the use of auxiliary tools will allow you to create an attractive and high-quality surface.

Packing

Finished plaster implemented in Kraft bags. Prepackaged composition can be stored under any conditions.

Colors

Without additional finishing the coating will look less aesthetic, therefore it will be more correct to paint the walls more correctly. The surface can be given any shade, using a thin brush, process the seams, and then - textured elements. The first layer is applied in one color, after a time the base is stained with another color. This technology will allow you to recreate a more natural imitation. Manufacturers of building products offer a wide selection of different colors and shades for works with plastered surfaces, including the addition of a coloring agent to the mixture that is being prepared for use.

The use of three colors in the design will give a feeling of a more embossed surface.

It is very important to process the bricks with an abrasive material so that the color composition is more pronounced.Colorless varnish applied to the plaster will give the surface a glossy look, while at the same time providing protection against fading under the influence of external factors.

Tips and tricks

To increase the strength of the walls before applying the plaster, it is necessary to lay a reinforcing mesh on the base, which will be very useful for areas near the windows and corners of rooms.

Decorative plaster will decorate any room, but its operational period is largely curtailed from the preliminary work, so alignment of the walls, elimination of various defects, processing with antiseptic and sealant are mandatory.

How to plaster the walls under the brick with your own hands, see the next video.