Dry plaster: varieties and uses

Some time ago, work with plaster began with the fact that it was necessary to prepare a mortar based on lime, cement or gypsum. However, dry plasters are available to modern consumers, which are already prepared for use. For such a material, only dilution with a liquid is necessary - and after that it can be used immediately. Today, sheets of drywall are also being created, which are also called dry plaster. After reading this article, you will learn about the varieties of such materials, about the features of their use.

Special features

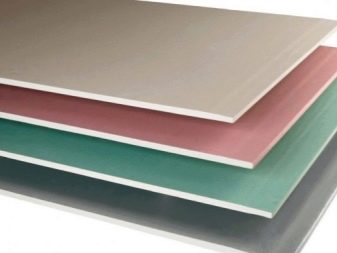

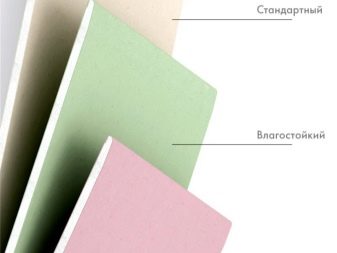

Plaster, which is dry, may be a special loose mixture or sheet material. The composition of this coating includes gypsum (more than 90%). So that the gypsum does not begin to crumble or become covered with cracks, it is trimmed from all sides using paper or cardboard covering. In addition, this material consists of organic substances that differ in viscosity, which make it more durable and durable.

Drywall is versatile: it is suitable for a variety of reasons.

Purpose

Dry plaster material is used to make the base as smooth as possible, to prepare the surface for final finishing. However, these materials can be used for finishing, but for this it is better to choose a decorative plaster mixture. For technical or auxiliary premises, the usual material is also quite suitable.

Pros and cons of drywall

Gypsum plasterboard has many advantages.

- The speed of installation work. Work with sheet material is much faster than with conventional ones. An additional advantage is that after installing the drywall does not have to wait before the implementation of further finishing.

- Soundproofing. Drywall is able to repay the sound.

- Increased resistance to fire. This coating is not capable of spreading fire, it does not support it. Only the part that is not drywall (for example, paper) will be smoldered.

- Environmental friendliness, safety. When creating sheet materials, substances that negatively affect human health are not used.

- Sheet materials are most often sold at more reasonable prices than liquid.

However, drywall sheets have some disadvantages:

- Hydrophilicity The sheet material does not have a high resistance to moisture (even if it is applied to a special moisture-resistant coating). If suddenly you encounter such a problem as flooding, you will have to re-trim the surface.

- Low strength. Do not hang furniture, a TV, or other heavy objects on drywall sheets.

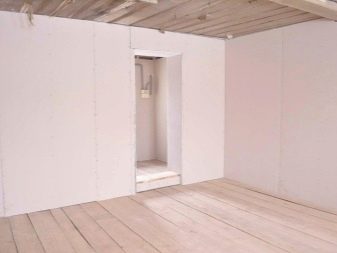

Installation of sheet materials

You can install drywall sheets in different ways. Usually sheet materials prefer to install on the frame or adhesive compositions.

Frame

First of all, it will be necessary to create and install an aluminum profile frame. Then on this basis is attached sheet material (for this you need to use screws).

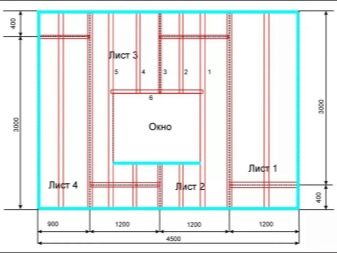

The installation of drywall is a series of sequential actions:

- Prepare the surface for mounting the profile. It will be necessary to remove noticeable defects, otherwise the dowels holding the frame may fall off together with the parts of the base.

- Install the start profile. This element should be below the surface. It is very important, because the whole frame will be mounted exactly on it. Perform a markup and do not forget about the use of the building level.

- Then mount the top profile onto the surface.

- Mount the upright racks, which are designed to connect the lower and upper profiles. To prevent any gaps when mounting drywall sheets, mount the racks 40 cm apart.

- Install sheet material on the frame using a screwdriver and screws. To avoid large gaps, butt the sheets.

Glue

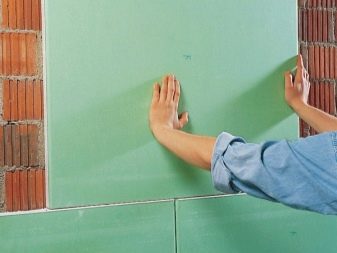

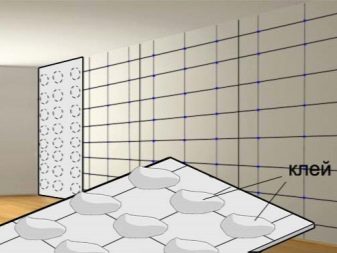

Plasterboard sheets can be fixed on the surface using special construction adhesive materials. Mix material with moisture, considering the proportions that are on the package. The mixture should be uniform and quite thick to make it easier to apply to the substrate.

Since plasterboard materials are quite heavy, it can be inconvenient and rather dangerous to mount them alone.

It is recommended to install such sheets together with a partner:

- First, thoroughly clean the ceiling or walls on which the plaster mix will be applied. You can do this using a grinding machine or sandpaper.

- Apply a primer to the substrate. So you improve adhesion (surfaces and glue will join each other as well as possible).

- When the primer is dry, apply an adhesive to the substrate. Do this on the center of the base and around its perimeter. Fragments of the adhesive should be quite voluminous, large. You can also apply glue to the panel itself.

- Apply drywall to the wall and make sure that it is installed as it should be, applying for this building level.

When the installation is complete, let the adhesive material harden. Most often, the packaging says how much time it will take. With the help of finishing putty material, cover the joints between the sheets,and after that you will be able to proceed to the finishing finish (gluing wallpaper, installing tile coatings, painting the surface). This is the method that causes the least trouble.

Even a person who has never before engaged in the installation of plasterboard elements can put sheet material in this way.

The nuances of installation work

To achieve excellent results of installation work and get the most durable coating, It is worth considering some recommendations:

- Build all necessary communications prior to the installation of drywall sheets.

- In rooms where the risk of fire is quite high, it is better to use plasterboard coatings that have a refractory layer.

- Do not install in the cold (the temperature during operation must be at least +5 degrees). Otherwise, it is possible that the cardboard or paper coating will separate from the drywall sheet.

- You should not use ordinary plasterboard sheets in rooms where the humidity is quite high. It is better to choose for this coating, on which there is a layer resistant to the effects of a liquid.

- Dry plastering materials in the form of sheets should not be used for exterior walls.

Special blends

There are several varieties of dry plaster material, which is used by mixing it with moisture. It is worthwhile to consider in more detail the features of each type of such materials.

Cement

Dry cement-based plaster compositions are chosen for various substrates: they are suitable for both interior and facade walls. This feature attracts many consumers. Such materials consist of sand and cement. Additional components are also used: fillers that improve adhesion and make plaster more viscous.

This material is not suitable for bases that are wet. Before using such plaster walls and ceilings should be made as dry as possible. In addition, a special primer should be applied to the ceiling or wall, which penetrates deep into the substrate.

Usually the surface dries out in three days, sometimes it takes less time - 24 hours. The coating gains strength for about seven days.

Lime

This is a traditional option, it has been popular for more than a dozen years.Lime plasters consist of cement (there is not much of it in such materials), sand and lime. Such materials are usually used for internal walls, because they are not resistant to the effects of liquids. The main advantage of these materials is cost, which is more than acceptable for consumers.

However, such coatings do not have a long service life, and besides, they need a lot of time to harden completely — about 48 hours –– and gain strength (this may take a month).

Gypsum

Gypsum plastering materials are very popular, because the finishing work with such compounds are usually carried out in the shortest possible time. They include polymeric fillers and gypsum. These materials are suitable for use on interior walls. The main advantage of gypsum-based formulations is that you don't need to finish, because the base eventually turns out to be very smooth. Such materials also have disadvantages: low mechanical strength and low resistance to fluid.

Before applying the gypsum plaster should make the surface as smooth as possible and remove allpollution. Dilute the material with water, focusing on the proportions that are usually indicated on the packaging. Apply the plaster to the substrate using a trowel and make the layer even. Typically, these coatings become dry during the day and gain strength in about seven days.

Selection and use

Selecting the most suitable dry plaster for indoor work, lumber, frame house and so on, you should pay particular attention to the composition of the material. Some mixtures are only suitable for interior walls, such plaster can not be used for facade surfaces. Certain restrictions will also be encountered when working in rooms where the humidity level is rather high.

It is recommended to select the material as carefully as possible., taking into account not only the properties of the plaster, but also the conditions for its future use.

In order not to be disappointed in the results of finishing work, you should always focus on the recommendations of the manufacturer, which can be found in the instructions.

For more on dry plaster, see below.