Silicone plaster: pros and cons

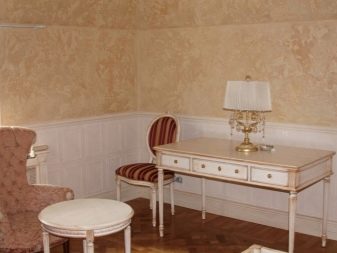

Silicone plaster - the material intended for finishing wall decoration. It is used for both outdoor and indoor applications. The composition has two main functions: leveling and decorative. Using the mixture it is possible to simultaneously level the surface and increase its aesthetic qualities. Due to this feature, the use of silicone plaster reduces the time and financial costs associated with the repair.

Special features

This type of plaster consists of silicone resins, various fabric fibers. The composition also adds special additives that improve the properties of the material. Thanks to such components the coating is durable and resistant to weathering..

Silicone plaster - material, ready to application. Does not need cultivation by water.May have a different color range. The mixture is allowed to paint in the desired tone with the help of color schemes.

Depending on the type of material, the composition has a grain size of one and a half to three mm. It is possible to use plaster at temperatures from +5 to + 30 ° С, while the dried surface can withstand significant temperature variations (-50 ... + 70 ° С).

Allowed to apply the mixture on gas silicate blocks, surfaces made of concrete, gypsum, wood, lime or cement, previously laid leveling plaster. It is not recommended to apply the composition to oil, paint or varnish coatings.

Species

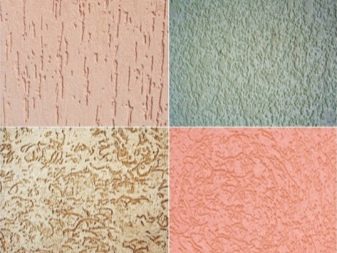

Depending on how the surface will turn out after the application of silicone plaster, the mixtures are divided into the following types:

- Bark beetle Such a composition after application forms a surface that is asymmetrically “stripped” by grooves and lines that visually resemble the paths of wood pests.

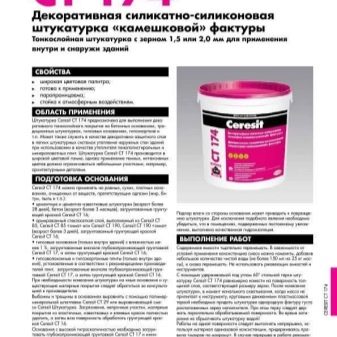

- Kameshkovaya. Due to the large grain, this textured plaster looks like marble chips.

- The Wing. When dried, it resembles fleece.

On the market there are mixtures for outdoor use. As a rule, such compositions have a coarse texture, thanks to which the surface has been able to retain its visual appeal for decades.For the improvement of interiors manufacturers make plaster for interior work. In order to save, you can buy a universal composition that is suitable for use both indoors and outdoors.

Manufacturers produce silicate-silicone plaster. Depending on the modification, it may have any of the above textures. The main difference of this mixture is the presence of potassium glass in the composition. Due to such an additive, the material acquires additional resistance to frost and higher performance.

Advantages and disadvantages

Any silicone-based façade blend is renowned for its durability. This lining retains its aesthetic qualities for 20 years even when exposed to rain, snow, hail, ultraviolet radiation and temperature extremes. The composition is easily applied to almost any base. It has an economical consumption and high durability.

Also facade mix:

- Elastic due to silicone. Due to this feature on the finished walls, the formation of cracks is excluded (even with a possible displacement of the structure).

- Watertight.Facing is reliable protection of walls from moisture penetration.

- Possess excellent vapor permeability. Due to this property, the walls do not accumulate condensate.

- They do not shrink, so that they do not crack when dried and used.

- Do not possess a smell.

- Non-toxic and non-flammable.

- Unlike cement and acrylic compositions, they do not attract dirt. Easily “self-clean” when raining.

- They do not absorb salts, due to which whitish spots do not remain on the surface of the facade. Due to this peculiarity, the material can be used in any climatic zones (even in coastal areas with salt saturated with air).

- Plaster with silicone base does not affect mold and fungus. Also, the mixture perfectly retains heat, helping to improve the thermal insulation of the building structure. For finishing the facade of the building, silicone plaster is recognized as one of the best facing materials.

Its significant drawback is the high price. The rates for such mixtures are much higher than the cost of other types of decorative plasters. Also the disadvantages include the complexity of dismantling.

Manufacturers

Silicone-based plaster is produced by many companies.However, the leading position in sales is only a few manufacturers. The most popular brand is Ceresitmanufactured by Henkel. A mixture of different colors is sold in buckets of 25 kg. The manufacturer does not produce universal formulations. On the market you can find plaster for exterior or interior work. Such compounds do not contain toxic components. The use of the mixture allows you to create a thin but durable decorative lining.

Also, the trust of consumers was able to win the firm. Kreisel. The manufacturer produces mixtures for exterior and interior decoration, as well as silicate-silicone materials. One of the main advantages of Kraysel plaster is a rich choice of colors, numbering more than four hundred shades. A feature of the compositions is the possibility of machine deposition on the surface.

The leaders in the production and sales of silicone plasters include the company. Weber. The compositions are intended for lining as wall interior surfaces and facades, as well as finishing the ceilings. All the proposed mixtures are available in white (under the following tinting). Weber building products are characterized by a high level of adhesion to any base.

Popular domestic materials include plaster. Bolars. The products of this brand have high aesthetic qualities, resistance to mechanical stress, durability. Due to the extensive color palette using a mixture of Bolars, it is possible to realize any design ideas.

Basis preparation and plastering

Before starting work, measure the surface area that you plan to process. Next, you need to calculate how much material is required for finishing. The amount of plaster will directly depend on the area of the base and the thickness of the facing decorative layer.

After the calculations, the preparatory work is carried out:

- If necessary, dismantled the old finish.

- Removed traces of debris, dust and various contaminants.

The prepared base should be coated with a primer suitable for the subsequent application of silicone plaster.

After the soil dries, a decorative mixture is applied. Due to the elasticity of the composition is easy to work: it quickly and effortlessly lays a thin layer on the base. The material is applied using a spatula or roller. Sometimes a broom, broom and other improvised means are used for these purposes to help create the most textured layer.The compositions can also be applied using special devices (if this type of plaster is suitable for machine application).

When finishing the surface, it is important that the overlay is the same over the entire base. When facing the facade, a difference of 1-2 millimeters will not be noticeable, but during internal work such a flaw will immediately "catch the eye." If it is necessary to apply 2 or more layers, you should wait until the previous one is completely dry. Putting plaster on the walls is an easy job. However, it requires certain skills and abilities. If they are not available, it is better to seek help from hired builders.

Reviews

Silicone-based plaster went on sale later than other types of mixtures. Thanks to its many advantages, the material quickly gained the trust of consumers. According to buyers, silicone blends are compositions that can be used to finish the facade of a “once and for all” structure. Consumers say that the applied plaster does not change its texture and does not fade over decades.

On silicone plaster buyers leave positive feedback.The only disadvantage that they have identified - the high cost of material. However, many note that the high cost of production justifies its long service life. Having spent time on a quality mixture, you can forget about the next cladding of the facade for decades.

Consumers also noted:

- easy application of the mixture;

- resistance to frost, temperature changes, high humidity;

- resistance to cracking.

Silicone plaster is a modern finishing material that will be popular for a long time. Durable and wear-resistant compositions will not only give a spectacular look to the building, but also reliably protect its foundation from adverse external influences.

This video presents one of the master classes on applying silicone facade plaster at the international festival "Shaman-Fest" Stroy-Fest2017.