Solvent 646: technical characteristics and application

Solvents are special volatile compounds, their purpose is to effectively dilute other materials. They can have both organic and inorganic nature and are used to make lacquers and enamels suitable for the consistency of repair work.

One of the most popular solvents is the composition of the brand 646 - it has found wide application both in everyday life and in industrial construction.

Properties and composition

Solvent 646 is distinguished by a multicomponent formula, it is an active substance that is commonly used for all types of repair, finishing and construction works. It is necessary in working with enamels and paints on a nitro-base, and is also optimal for dissolving epoxy and glyptal primers. It is noteworthy that after all volatiles evaporate, the surface becomes slightly shiny, glossy.

As a rule, the solvent has no color.But in some cases, the appearance of a slight yellow tint is allowed, it is characterized by a pungent unpleasant odor.

The structure of the substance consists of the following active ingredients:

- acetone - 7%;

- ethyl cellosolve - 8%;

- ethyl alcohol - 10%;

- butyl acetate - 10%;

- butanol - 15%;

- toluene - 50%.

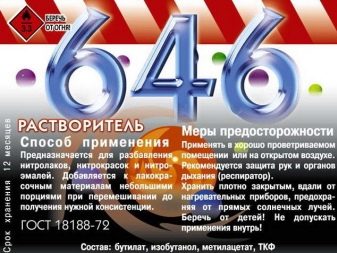

The production of solvents is allowed in the mandatory compliance with the existing State Standards, in this case the standard 18188-72 is valid - this is a necessary measure, since the solvent of this brand is often used for the manufacture of synthetic drugs.

For the same reason, active technical work is currently underway to change the composition of the solvent in such a way as to limit the scope of its illegal use.

The popularity and wide use of solvent 646 is due to its high consumer characteristics:

- reasonable price - this tool is sold in all hardware and construction stores and has a low cost;

- practicality - especially for consumers, the label contains full information and how to use the composition, so that everyone, even without any experience in finishing, can deal with the peculiarities of the work;

- functionality - the solvent has a multicomponent structure, so it can interact with almost any type of material;

- used for high-quality degreasing of surfaces, after work does not leave any traces on the surface;

- after surface treatment gives it a glossy shade;

- Contact with this substance does not cause burns and irritation on the skin.

There are solvent and disadvantages, the most significant include:

- high degree of toxicity - the material is classified as hazard class III, which is why all work must be performed strictly using personal protective equipment (respirator, goggles and gloves);

- fire hazard - it is strictly forbidden to work near sources of fire, it is forbidden to smoke near the work site;

- harsh chemical odor - surface treatment should be carried out in a well-ventilated area, and you should also take care of the protection of the organs of vision, since the evaporation of this solvent can irritate the mucous membrane of the eyes;

- special storage conditions - it is necessary to use sealed closed containers, solvent can be stored only outside the premises.

High demand for the product gave rise to an unpleasant phenomenon - today the market is literally flooded with a large number of fakes, and in addition, users have noted a deterioration in the quality characteristics even in products manufactured by well-known manufacturers.

Many consumers confuse the 646 and 647 solvents. In fact, they are quite similar in their functionality and physicotechnical properties. In addition, both formulations are produced in small 0.5 l and 1 l tanks for household needs and barrels - for industrial. They are produced in Russia and have very wide application.

The difference lies in their composition. So, M646 includes ethanol, toluene, butyl acetate and ethyl cellosolve, and 647 has the same components, except acetone. In this regard, it is less aggressive and more suitable for delicate surfaces that need careful handling.

It should be noted separately that the use of 646 solvent requires accuracy and compliance with the necessary safety regulations, since the composition is classified as highly active, therefore it interacts well with glyphthalic and epoxy compounds, as well as nitrolak and nitro-enamels.

But brand 647 is more often bought for dilution of nitrocellulose materials in order to give them the desired viscosity, it allows you to smooth strokes and paint on the surface.

Specifications

Composition 646 in its structure has dangerous volatile components and exhibits special physical and technical properties:

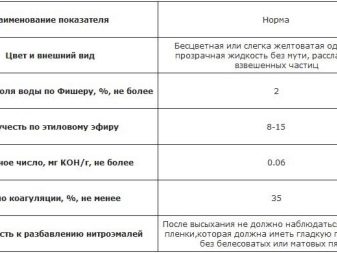

- colorless or light yellow tint;

- t spontaneous combustion +403 degrees;

- t boil +59 degrees;

- t flash -7 degrees;

- material density - 0.87 g / cm3;

- does not freeze, therefore, such an indicator as t freezing is not calculated;

- does not change viscosity.

In addition to these indicators, you should separately dwell on the passport of the solvent, which for an ordinary person far from the production of paint and varnish products, will not say anything, however, technologists of manufacturing enterprises always pay attention to a number of indicators, depending on the numerical value of which they can prohibit or, conversely, , recommend the use of a product. For the product in question, these characteristics are as follows:

- acid number - 0.06 mg / KOH / g;

- octane number - 40g / 0;

- mass fraction of water - 0.09%;

- degree of volatility - 12;

- specific weight - 0.68 kg / l.

The shelf life does not exceed 1 year in case of compliance with absolute tightness of storage.

Application area

The first thing you need to know about using solvent 646 is that you can work with it only in the temperature range from +5 to +30 degrees, the humidity should not exceed 85%.

The solvent is introduced into the working medium in small portions and actively stirred so as to achieve the desired consistency.

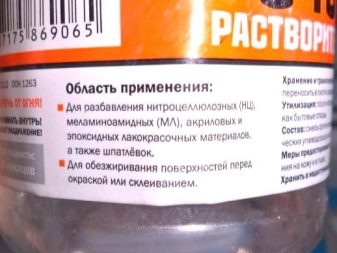

The composition dissolves primer, putty, all kinds of varnishes and enamels, and in addition, they can clean up randomly on the surface and clothing varnishes and paints, as well as return rollers and brushes to workable condition after painting.

More precisely, the scope of its effectiveness involves working with nitrocellulose, glyptal, and acrylic, melaninoamide and epoxy varnishes, paints and enamels.

It is used as an active ingredient in the production of these materials and in everyday life, in order to dilute them to the optimum state before use.

This the reagent is often introduced into putty and primer materials in order to create a functional consistency that will allow creating perfectly smooth surfaces.

Separately, it is necessary to dwell on the issue of the use of solvent to degrease the surface. This part of the work is extremely important, as non-degreased materials significantly reduce adhesion during dyeing and varnishing, as a result, the applied layer is stained or peeled off.

Yes, the use of solvent copes with this task, but its application has its own nuances. To begin with, it should be borne in mind that this composition is one of the most aggressive among all the analogues, therefore, the work requires caution and care, as the components of the composition can dissolve the base. This composition can be degreased bath and other metal objects, cleaning nozzles also under the force of the composition. But for the preparation of plastic, such a solvent should not be used - acetone is aggressive in relation to plastic, so in working with it one should prefer the brand 647.

The recommended material consumption during degreasing is:

- external coatings - 0.147 kg / m2;

- metal and wood coatings - 0.120 kg / m2;

- concrete surfaces - 0.138 kg / m2.

Manufacturers

As already mentioned, in recent years, the quality of the 646 brand solvents on the market has deteriorated, and in addition, a wide variety of fakes have appeared.Therefore, it is very important to purchase a product of such a manufacturer who has won the trust of consumers due to the exceptional quality and reliability, as well as stability of work over the years. Users recommend to give preference to products from several manufacturers:

- Dmitriev Chemical Plant. This company is one of the oldest in Russia, but at the same time one of the most dynamically developing. The company manufactures products for the needs of the paint-and-lacquer, leather, rubber, and food industry. Products of this brand are known far beyond the borders of our country - for several decades products have been supplied to 70 countries of the world.

- Verkhnevolzhskaya paint and varnish company. This is another leading supplier of enamels, paints and varnishes in the territory of our country, as well as in the CIS countries and abroad. The assortment list of products includes a wide range of paints and varnishes, solvents and primers.

- "Polikom". Domestic brand specializing in the production of household and industrial chemicals. The company is fully automated, and manufactured products meet all major international standards.In addition, users note the universal solvent "Tex", which is always in high demand in the modern market.

All these brands are characterized by increased attention to quality control, they work and produce solvents in strict accordance with current GOST standards.

Safety

Solvent 646 is characterized by special operating and storage conditions. The composition is bottled in a special container: from 0.5 liter bottles to barrels of 200 liters.

When transporting and storing the composition, one should not forget that the product is classified as flammable, therefore:

- the glass or metal container in which the material is contained must be tightly packed and closed, water should not be allowed, and contact with direct UV radiation and elevated temperatures should be avoided;

- the room where the composition is stored should be well ventilated, it should ensure the absolute absence of ultraviolet rays and sources of fire.

To ensure that building and finishing works using a solvent are as safe as possible,Compliance with all of the following requirements is required:

- it must always be remembered that it is extremely toxic;

- It is important to keep your eyes free of solvent.

- during surface treatment it is necessary to use glasses, gloves and a respirator;

- In case of contact of the solvent with the skin, if it gets on the mucous membranes, wash the affected area with plenty of water at room temperature.

If these safety rules are neglected, the consequences can be the most unpleasant:

- eye and respiratory irritation, bronchopulmonary spasm;

- poisoning - vapors of a substance can be absorbed not only through the respiratory organs, but also through the skin, therefore they can cause serious damage to the central nervous system, and in addition, to the kidneys, organs of the gastrointestinal tract;

- With prolonged contact with this solvent, severe dermatitis may appear on the skin;

- prolonged exposure of the product to the human body causes a change in the state and structure of the bone marrow and blood.

Special attention should be paid to fire safety issues when “communicating” with this product, namely:

- Protect the storage area and working space of the solvent from contact with fire and its potential sources (sparks, cigarettes that have not been extinguished, heating appliances);

- the storage tank should be fairly tightly closed, since the mixture of solvent vapors and air has explosive properties, and the accumulation of a critical dosage of vapors in the air, if left open, can occur very quickly;

- it is necessary to exclude the contact of the solvent with a hydroperiod, as well as caustic nitric and acetic acids, otherwise the probability of formation of an explosive mixture is high;

- a similar effect has the reaction of the solvent 646 with substances such as bromoform and chloroform.

Keep in mind that solvent vapors creep down because it is much heavier than air, which is why any fire can start even far from the source of fire, especially since it can reach a critical concentration when combined with air even at a temperature of 20 degrees - so do not expose yourself and the danger of your loved ones, try to create the most “closed” conditions of storage and use.

You will learn more about solvents in the next video.