Features of natural varnish

Every day, manufacturers offer all new materials for construction, which greatly simplify repair work. At the same time, to natural materials that have been used for more than a dozen years, consumer interest continues unabated. These means should include natural linseed oil.

Special features

In the construction and decoration of the premises is difficult to do without the use of wood. The material is absolutely safe in environmental terms. But the surface of wood needs special treatment in order to preserve all the properties of this material. For finishing surfaces often use paint, varnish. Many of these products can be harmful to the human body, have toxic components in the composition, therefore it is better to use natural materials when processing wood products.

Natural drying oil can be considered an absolutely safe means of health.. The composition is perfect for repair, often used in the design and restoration of works of art.

Since the drying oil is used to protect wooden surfaces, the composition can be used in beekeeping for treating hives.

The basis for the composition consists of flax or hemp oil, soybean, sunflower or rapeseed oil is also taken for production. Natural linseed oil is the most suitable option to protect the tree from moisture and parasites.

Dry oil is produced now in the same way as many years ago. This material has long been called "boiled butter". To obtain it, they took flaxseed oil or hemp, which was cooked for several hours at a very high temperature. In ancient times, amber and other resins were added to the composition, then this mixture was applied to wood products. Today such a mixture would rather be called varnish.

To date, this tool is more often used for applying on wooden surfaces inside the house, it is also suitable for processing a porous surface, which will then be painted. Drying oil can be used as a base for oil paint, putty.

When applying natural varnish, you can prevent the process of rotting wood surfaces and protect them from moisture. On the products treated with linseed, tree parasites will not start.

Specifications

Drying oil, which is produced by industrial enterprises, has certain requirements for its composition according to GOST 7931 76. According to this standard, a protective agent must have vegetable oil without solvent, 97% of drying oil is flax or hemp oil and 3% consists of oil composition with additives.

Drying oil is a light or dark oily liquid with a slight smell of oil. The lightest color will have a linseed oil from flax seed seeds, as its color is 8 times lighter than that of linseed oil produced from hemp oil.

The main advantages of this substance should be called:

- resistance to mechanical stress;

- surface protection against moisture;

- is absolutely harmless and environmentally friendly material;

- can significantly save when finishing the painting method;

- decorative wood impregnation will make the surface smoother, prepare for further processing.

When choosing a varnish in the store, you should check if there is a certificate of conformity for it, you should ask the seller about it. Drying oil with natural composition will have a dark brown color with a slight smell of used oil. But if a strong smell is felt, the drying oil is most likely a combination or it is oxol.

Combined formulations may include harmful substances, so look at the quality certificate will be superfluous.

Kinds

There are many types of decorative wood impregnation. Some of them are used indoors, and some are best used outside the home.

Natural drying oil is divided into two types:

- Polymerized. This composition undergoes heat treatment without the use of purge.

- Oxidized or oxidized. In its manufacture, the oil is languished for a long time at a very high temperature, and then purged.

Oil drying oil is used indoors as it is not particularly practical to use it outdoors. When buying, please note that oil oil costs more expensive than other options.

Apply natural linseed oil:

- when carrying out finishing works inside and outside the house;

- when painting flooring, window frames, doorways, walls;

- for priming products;

- in the composition of soil mixtures, plaster and paint;

- during restoration works;

- for pretreatment of products and surfaces before applying paint in order to increase adhesion;

- when diluting paints, putties and primers to obtain the necessary consistency;

- Often, natural oil is used for finishing work.

Linseed linseed oil is widely used for artistic and restoration work, it is applied for impregnation and priming before applying paint.

Natural flax linseed oil without fragrances has long been used in icon painting, during the restoration of paintings, as it is considered an excellent plasticizer. In ancient times, when other materials had not yet been invented, oil linseed oil was used to cover the icons. But as the linseed oil begins to turn black with time, the icons after some time needed restoration. For auxiliary materials for painting suitable linseed linseed natural linseed oil.

In the production of vegetable oil after heat treatment is mixed with driers.They accelerate the process of polymerization of the film. Choosing a mixture you need to see what kind of desiccant was used in its production process. If you take into account the standards, the drying agent in the varnish should not be added more than 5%.

When choosing, pay attention to the capacity where cobalt desiccant is added, as it is the safest. If you increase its percentage, then when applying the oil on the surface it is possible darkening and cracking.

Among other alternative means for treating wooden surfaces, it is still worth choosing a natural linseed oil. This tool is environmentally friendly, which favorably affects the human body. In addition, neither in the process of work nor after the impregnation of products from them will there be any harmful substances.

Manufacturers

Now on the shelves in the building and hardware stores you can find a huge selection of tools that are used during construction and repair work. A large selection of protective agents for wooden surfaces is presented by domestic and foreign manufacturers.

Good reviews received linseed oil from the Estonian manufacturer Vekker. Typically, the compositions of the manufacturer used in the restoration work. Apply Vekker oil when working with art products, while covering the icons. Drying oil drying in the shortest possible time, so there is no need to use more modern paints and varnishes.

After it is applied to the surface, a thin film is formed, which will serve to preserve the paint layer for a long time. When applying the drying oil there is no damage to gold leaf gilding. A day after application, the surface ceases to adhere to the hand. The oil should be kept out of reach of children in closed containers, and its shelf life is up to five years.

How to do it yourself?

If the shop drying oil was not at home, you can make it yourself.

We offer recipe for drying oil made at home. The process of making a product is as follows:

- it is necessary to take a metal pan and pour oil into it;

- within 4 hours, the oil is cooked over low heat;

- after evaporation of water, a desiccant should be added at the rate of 40 g per 1 liter of oil;

- The temperature is increased to 200 degrees and cooked for another 3 hours.

To check whether the composition is ready, you need to drop a little mixture on the glass. If the drop remains transparent, you can turn off the stove, as the drying oil is ready for use after pre-cooling.

For the preparation of desiccant rosin mixed with potassium permanganate. It is necessary to take 20 parts of rosin and melt it at a low temperature, then dilute one part of manganese peroxide and add it to the liquid.

If for manufacturing we take not flaxseed oil, but sunflower oil, then the final product will turn out to be a lighter color. Boil the linseed oil from sunflower oil in two ways - hot and cold.

To prepare the drying oil in the cold way:

- heat the oil, constantly stirring the base, bring it to a temperature of 150 degrees;

- then you should add a desiccant at the rate of 5-8%;

- in the process of adding all components should be thoroughly mixed;

- Remove the dishes from the heat and cool in the room.

To prepare the linseed oil in a hot way, you should:

- bring the oil to a temperature of 170 degrees, then you should add a desiccant, hoping that it should be added from 1.5 to 2.5% of the total volume;

- Before adding, the desiccant is pre-diluted with oil and then added to the hot mixture;

- after foaming has weakened, the temperature should be gradually increased to 280 degrees;

- Boil the mixture, stirring constantly, it is necessary for four hours.

To learn how to cook linseed oil, see the following video.

Application tips

Cooking oil in the room is quite problematic. It is better to carry out the cooking process on the street away from the spectators, especially you should not allow children to get in the container so that they do not get burned.

Instead of shop drying oil or cooked with your own hands, you can take a simple tool that will also protect a wooden surface well. To prepare you should take:

- casein;

- soap solution;

- hydrated lime.

After preparing the ingredients, they need to be mixed and then turpentine is added there. You can also add a little ammonia to the casein lime is not precipitated. This composition is perfect for processing wooden surfaces. Such a solution is resistant to water and mechanical damage, it will hold well on metal products, give them shine and protect from scratches.

For those who still choose the store version of drying oil, should describe the procedure for applying funds to the surface. Before you start, you need to prepare the wood, it should not be dirt or dust. The wooden surface must be knotless. If there are defects, they should be sanded. Before applying the varnish, the surface to be treated must be completely dry.

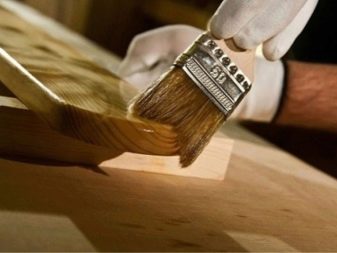

With a roller or large paint brush oil is applied to the product in 2 or 3 layers. Approximate consumption of the substance is 80 g per 1 sq. Km. m

When applying a natural improved drying oil, the oil is polymerized, while a part of it will penetrate into the depth of the material, and a thin protective layer creates the main amount.

After application from the roller, brushes and rags should be disposed of. Indoors it is necessary to open windows for airing. After a day, the product can be used.

Do not forget that the liner is a fire hazardous substance, so the jars with the mixture are not stored near the fire source. During the treatment in the room can not use electrical appliances and smoke. It will also be useful to prepare a fire extinguisher and other means for safety.