Combined Drying Oil Brand K 3: composition and characteristics

At construction and finishing works the most various materials are used. The tree is widely used in this area. But keep in mind that when it is applied, various problems may appear, not least of which is the appearance of fungus, mold and insects.

In this case, the use of drying oil, which (due to natural oils in its composition) is capable of creating a film that protects the surface and extends the life of the material, is capable of correcting the situation.

Features and specifications

Drying oil is a solution that forms the basis of a variety of oils. It can be made on the basis of sunflower, linseed, soybean oil. It is linseed oil that is present in all paint and varnish mixtures of the oil type.

To the drying process drying varnish took less than a long time, in its composition are introduced sikkativy. These components protect the coating treated with the solution from negative effects and prevent its deformation.

Currently, linseed oil is widely used in the field of construction and decoration, so it can be freely purchased in any specialized stores. If there is a need, its independent production is not difficult. The main ingredient for this is sunflower or linseed oil.

The compositions are divided into synthetic, oil and combined. Drying oil brand K 3 is a combination solution.

The main task of the combined drying oil K 3 is its use in the manufacture of oil paints and varnishes, as well as the dilution of thickened mixtures. In addition, it is used to impregnate wood surfaces that are being prepared for the application of oil paints.

It is possible to apply this structure as when carrying out external, and internal works. It protects well wooden surfaces from moisture and other adverse climatic conditions.

Speaking about the technical characteristics, it is necessary to note the transparency of the varnish of this brand. The shade of yellow is more pronounced for the second grade and less saturated for the first. When wood is treated with linseed oil, it acquires a rich noble shade, a pleasant shine appears.

The drying time of the composition depends on the temperature conditions in which the work is carried out. The most favorable temperature is about 20 degrees.. In this case, the coating will completely dry out in 24 hours. When working independently with the composition it should be used in small portions. Total weight must be tightly closed.

There are significant differences in the use of the combined drying oil of the K 3 and K 2 brands.

Composition K 2 is used when working with paints that will be used exclusively for interior decoration. It contributes to a more uniform drying of the material and the creation of a uniform smooth surface. Drying oil K 2 has a darker color than the first grade of composition K 3. At the same time, it is also transparent.

Application of any of the materials should be carried out on a previously prepared surface and with the condition that the wood is completely dry.Drying time for both solutions is the same.

Application

Combined linseed oil brand K 3 is popular and in demand, thanks to the possibility of its use in both internal and external works.

The difference between grades 1 and 2 is that they are used for paints of different shades. Since the first is more transparent, it is recommended to use it when working with light colors. The second gives saturation to darker and brighter paintwork materials.

There is a safety precaution (according to GOST), which is mandatory for execution when working with linseed oil. This is due to the fact that natural varnish has a high flammability index. Combined compositions require even greater caution in the application, as they are explosive materials. Therefore, an important point is to ban the storage of the solution near an open flame.

Wood consumption

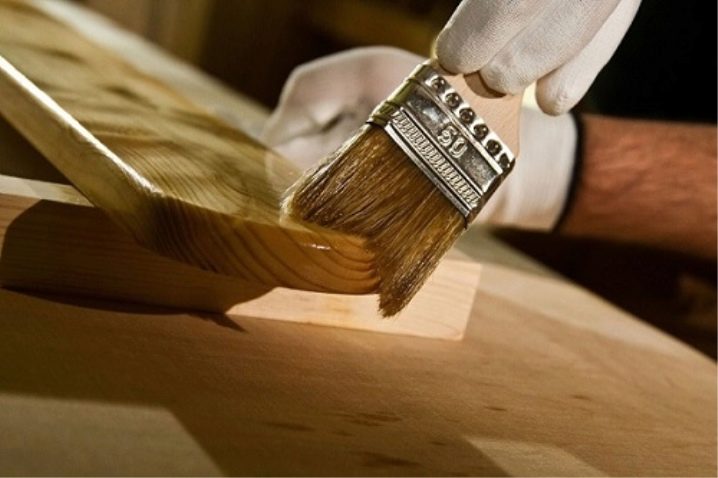

Before putting on the surface of the combined drying oil, it is required to process the base. It is necessary to clean it from dirt and degrease. The surface should not be wet. To apply the varnish and compounds with its content using a regular brush.With its help, the solution is applied to small areas of the base.

If voluminous work is intended, then to save time, the composition can be applied using a roller or sprayer.

The main point is considered thorough impregnation of the surface, so the composition is applied generously, all areas are treated. To impregnation was deeper, it is worth using hot linseed oil. If you count the approximate flow rate, it will be approximately 130-160 millimeters of solution per 1 square meter of surface.

Experts advise applying material in 2-3 layers, but this quantity is rather a recommendation. Their final number depends on the specific situation and is calculated as necessary. Draft will not benefit the treated surface, so it is better not to allow them.

If oil paints and varnishes are excessively thick, then it is rather difficult to work with them. In this case, to give the desired consistency can be used varnish K 3. This is also useful because the consumption of the paint itself will be much less.

When the work is finished, you should not keep used tools.Since the linseed oil is flammable and explosive, these elements can be dangerous, so they should be disposed of.

As for the storage of the remains of the composition itself, then it is necessary to choose a safe place for it, where direct sunlight does not penetrate. Also inadmissible is the presence of moisture, working electrical appliances and sources of open fire in the immediate vicinity.

Thickened composition should be diluted with a solvent that is combined with oil paints. The proportions should be approximately 1 to 10.

Application for breeding silverfish

Combined linseed oil K 3 is an indispensable tool in breeding silverfish. Its use is quite relevant, since the surface treated with this composition becomes durable, the paint does not peel off and is well tolerated by mechanical and other aggressive effects.

Serebryanka can cover a variety of foundations, such as wood, concrete and metal. It dries quickly and is completely non-toxic. Products covered with this composition look original and unusual.

Dilution of silver linseed oil does not cause difficulties. In this case proportions 1 to 3 or 1 to 4 should be observed, where 3 and 4 are drying oil.

In too thick mixture, which turned out after mixing, you can add white spirit.

After the performed manipulations, you can proceed directly to staining. The surface, as well as before applying any paint, must be prepared and cleaned. In the presence of the old coating is necessary to use the soil. Serebryanka applied in 2-3 layers. The material processed by it becomes heat-resistant and resistant to temperature extremes.

Subtleties of choice

First of all, when buying a combined K 3 varnish, you need to make sure that the material you are offering is of high quality and safe. This can be done in appearance.

It is necessary to pay attention to the transparency of the product, its homogeneity, the presence of sediment.. If the product visually satisfied the consumer, it would not be superfluous to ask for the necessary documents and certificates that are able to confirm its quality and compliance with GOST.

The fact that you can continue to cover the surface treated with linseed oil, learn from the following video.