Drying oil: what it is, composition and properties

In any repair and finishing work, as a rule, a lot of wood materials are used. To effectively protect the tree from the damaging effects of moisture, fungi and mold, it is impregnated with a layer of drying oil.

Special features

In Soviet times, linseed oil was almost the only tool that was used for the treatment of wooden buildings and individual products. Now the materials market is much higher, the industry offers a large selection of more modern and practical coatings. However, admirers of drying oil exist to this day.

The use of drying oil can significantly increase the durability of wooden structures, which is especially important for rafters, as they are highly susceptible to water and condensate.

In addition, the impregnation of this composition effectively protects the coating from temperature fluctuations, high humidity and destructive weather effects of all types.

When treating wood with linseed oil, a film is formed on it, which is solid, but at the same time plastic. It is this material that protects the material from external adverse effects, as well as from the appearance of mold and fungal reproduction. It is the linseed oil that will prevent the wood from rotting, and besides, its use significantly minimizes the consumption of enamels and paint.which can be used as a finishing finishing material. As a rule, linseed oil is applied in 2-3 layers, and then only painted with paints.

Another undoubted advantage of the solution is its low price and availability. Basically, linseed oil is taken for interior finishing, but the use in the open space causes only a temporary effect, which requires mandatory coating with paints or varnishing in the future.

Specifications

The mechanism of the drying oil is based on the physical properties of its constituent components.

If vegetable oil is applied to any surface and left in the fresh air, then under the influence of heat, sunlight and oxygen, it begins to thicken. If the oil is applied in a thin layer, it dries out and forms a semi-solid composition.. This quality is characteristic of such oils, the main component of which are linolenic and linoleic acids. Moreover, the higher the concentration of these acids, the more pronounced they show the property of solidification.

In oils of different types, the content of these components usually vary. For example, in linseed oil they account for 80%, in hemp 70%, but in sunflower and nut their content is less from 30 to 45%, and of course, in olive oil, the acid is 40%.

Mineral-based oils do not contain fatty acids from acids at all, due to which they do not dry out in air.

However, in its natural form without heat treatment, vegetable oils are oxidized quite rarely, even if they contain significant amounts of fatty acids. That is why to stabilize the wood and reduce the drying period, the composition is processed and injected into it dryers - various metal salts, which significantly reduce the hardening time of the oil. Due to this composition, the drying oil after drying can dry from 6 to 36 hours, but, as a rule, modern means harden within 24 hours.

Shelf life of drying oils of any type is at least 3 years.

Kinds

Nowadays on the market are varnishes, characterized by different compositions and spheres of use.

Natural

This is a type of coating that is made from environmentally friendly raw materials and therefore is absolutely safe for human health. Part of the siccative has a small percentage, so the rate of hardening of such a coating is slightly higher than the other types of drying oil.

The natural product has a yellow color without foreign matter and sediment at the bottom of the tank.

This product is manufactured in accordance with the requirements of GOST, according to which its technical parameters are set:

- the proportion of oil to the driers - 97 to 3;

- the absence of any odor chemicals;

- hardening at t 20-22 degrees;

- curing rate - 24 hours;

- acidity level - below 5 mg / KOH;

- the presence of components containing phosphorus is not higher than 0.015%;

- material density -0.95 g / m³.

Such linseed oil is popular for processing wooden crates and other elements that do not require further painting.

Semi-natural

The main component of such drying oils are oils, the concentration of which is slightly lower in comparison with natural varieties of drying oil.As a rule, their share does not exceed 55% of the total. Base oils are diluted with driers and solvent. This product belongs to a lower price group than all other coating options and is most often used as an additive.

By the way, you can learn about its purpose by special marking:

- AT - it is added to the varnishes and paints intended for external works;

- PV - used in the preparation of putty;

- CM - combines with a primer to improve the quality of wall coating and ceiling coatings.

The solvent in the composition of oxol will come to her a sharp unpleasant smell, which, moreover, does not erode for quite a long time. Surface treated semi-natural composition wears out pretty quicklytherefore, treated wood necessarily needs finishing cladding with paints or enamels.

Combined

This type of drying oil is produced by oxidation of solidifying natural oils and the introduction of a solvent, and the proportion of the latter to oils is about 30 to 70. This composition is practically not used for decorative finishing works, it is most common in the manufacture of oil paints type K2 / K4 / K12 - for interior work, and K3 / K5 - for facade.

The composition is transparent with a slight yellowish sheen, the applied layer hardens in 24 hours.

Synthetic

The main difference of this type of drying oil from the others is the use of a synthetic composition instead of natural oil, and such compositions do not have the requirements of GOST, their standards and standards for the ratio of the main components are governed by the specifications.

As a rule, such products have a low price, however, and their quality corresponds to the cost - the coating is not hygroscopic and has a very unpleasant odor. It does not make sense to use it for finishing.. These varnishes have been used in the manufacture of plaster solutions and putty mixtures.

Compositional

The main components of such liquids are oxidized oils and gasoline diluted with rosin. Most often take flaxseed, cotton and rapeseed oil. These drying oils suitable for tiling as the basis under a covering enamels and varnishing.

Manufacturers

In Russia, large varnish-and-paint enterprises make linseed oil:

- "Kotovsky paint and varnish factory" (Tambov Region);

- "Perm paint factory" (Permian);

- "Management Company ZLKZ" (Sergiev Posad);

- "Ufa paint factory" (Bashkortostan);

- "Azov paint factory" (Rostov region);

- "Bobrovsky Experimental Plant" (Sverdlovsk region).

For many decades, linseed oil has always been a growing demand from consumers. That is why its manufacture is engaged in well-known and large enterprises.

The most popular products of the following brands:

- "Tex". This company sells already prepared for impregnation of linseed oil. It is available for sale in containers from 0.5 to 8 kg. Distinctive features of the products of this brand are high speed of hardening, a significant reduction in paint consumption during finishing. This varnish can be purchased as a primer.

- "Coachman". Produces an impregnating agent in strict accordance with the requirements of GOST and all SanPiNs. The goods arrive in stores in packaged form, the weight of the container is 0.8-20 kg.

- Isolate. It is considered one of the highest quality materials, the packaging is produced in containers from 0.5 to 200 liters. The disadvantage of this brand is to mention the fact that they produce linseed oil only to order and only wholesale large quantities.

- "Vesta-Color". Offers linseed oil both wholesale and retail. Impregnation produced by this manufacturer is characterized by exceptional quality and excellent performance properties.

- Himtek. Engaged in the production of oxols over two decades. The product of this brand has a decent quality and affordable price for the average Russian. The stores come in containers of various volumes, so that every consumer can buy packaging that corresponds to his scope of work.

The varnish of the listed brands over the years has proven its practicality and high quality, which is why it is these manufacturers who should be given preference when choosing impregnation.

How to do it yourself?

If you do not have the opportunity to go to the building or hardware store, but at the same time a lot of vegetable oil has accumulated at home, then it is quite possible to make drying oil with your own hands. Most often at home use linseed and sunflower oil.

For home production of impregnation based on flax composition you will need:

- metal container (basin or bucket, pan or ladle);

- heat source (gas or electric stove);

- rosin;

- potassium permanganate;

- personal protective equipment (respirator and rubber gloves).

The technology of making drying oils is simple: to begin with, the oil is poured into a vessel and gradually brought to a boil - it occurs at t 110 degrees. At this point, the oil begins to release the water contained in its composition, it begins to evaporate and bubbles form on the surface. Thus, the oil is boiled for about 4 hours. Wherein it is important that the temperature of the liquid does not exceed 160 degrees.

Attention: linseed oil is a combustible material of increased fire hazard class, therefore it is impossible to pour oil into the tank to the top - fill the container with no more than half.

At the end of evaporation, a siccative is introduced into a thickened drying oil in a ratio of 30 g of substance to one liter of oil. At the time of adding this component begins a strong foaming, which can lead to injuries and burns. To prevent this from happening, the desiccant is administered gradually in small portions, after which the heat effect is increased to 200 degrees and continue to cook the composition for another 3-5 hours.

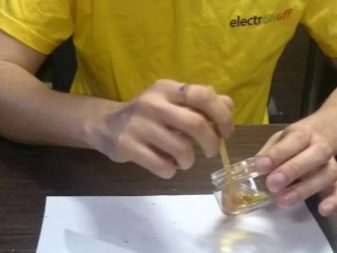

To check the readiness of the solution, you need to put a small drop of "homegrown" linens on ordinary glass, and if it is transparent, then the solution can be used.

As the main desiccant use a mixture of rosin with manganese in the ratio of 20 to 1, and first rosin is brought to melting, and only then permanganate is mixed in.

Drying oil from sunflower also reliably protects wood or plywood, as well as liquid based on flax, the only difference is in the finishing shade - linseed oil on sunflower oil will give a lighter tone.

Whatever way of self-preparation of drying oil is chosen, the main principle is the need to remove all the water from the oil and to achieve the oxidation of various impurities. This can be achieved only by long-term heat treatment, so you need to be patient and protective equipment and take care of compliance with the rules of fire safety and good ventilation.

Scope of use

The scope of drying oil is directly related to its varieties and composition.

So, natural solutions are widely used for priming wood and metal surfacesas well as porous plastered coatings. In addition, the material is used for breeding putty, thick paints, lubricating pastes and all kinds of putties.Linen impregnations are often treated with doors and window spans before the finish painting.

Hemp linseed is suitable only for priming coatings of all types, diluting enamels, paints and making putty.

Drying-oxol has physical and technical characteristics, thanks to which it is possible to use it together with a wide variety of painting materials. It is noted that oxol films have good density and glossy shine, as well as resistance to external adverse factors. Such linseed oil is deeply absorbed into any surface to be treated, therefore it is used to protect wood structures, rafters and floors. However, it is not recommended to use for finishing the floor.

The combined composition is a polymer olive, obtained as a result of dehydration of oils with the addition of white spirit (its percentage is 30%), such drying oil has found its application in the manufacture of thick rubbers.

Alkyd impregnation is formed from resins diluted with chemical solvents and various modified oils. These solutions are more practical and more economical than natural ones, sincefor the production of 1 ton of such drying oil, only 300 kg of oil is taken. Such compounds are optimal for wood processing. and protect it from the adverse effects of weathering.

Composite linseed oil has a relatively low cost, so the demand for it is consistently high. It is used for effective dilution of enamels during various painting works.. You should not take it for impregnation, since almost all the film will remain on the surface of the wood. It should focus on the fact that this composition has a rather sharp unpleasant odor, and it is quite problematic to save it from the room. Therefore, all work is best done either outdoors or in an apartment with good ventilation.

Summarizing all the above, we can conclude that the main areas of use of linseed oil can be considered:

- priming of plastered surfaces and concrete for painting;

- production of putty and mastic;

- impregnation of wood products;

- making putty;

- high-quality preparation of thickened paints for work;

- dilution of liquid paints and enamels.

Consumption per 1 m²

For surface treatment, linseed oil is applied quite abundantly, this allows the wood fibers to become well saturated. If deep penetration of the composition is required, the drying oil should be heated to 80-90 degrees.

For to treat 1 square meter of surface, it is necessary to 130 ml of drying oil. As a rule, this volume is enough for 2-3 layers. However, in some cases there is a need for additional impregnation.

If linseed oil is used for dilution of paint, then there is no strict proportion in which to dilute the composition - oil is injected until the paint reaches a consistency suitable for use, that is, until the composition will not acquire the desired degree of density. This method can significantly reduce paint consumption and, consequently, the cost of it without the slightest damage to the quality of painting work.

Application

We will dwell on the technology of the use of linseed for wood impregnation

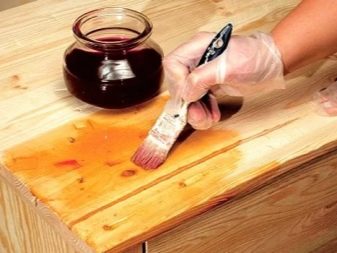

To begin with, all wooden elements are cleaned of dust, dirt and degreased. To apply a layer of varnish, use a brush with long bristles, a paint roller, a paint sprayer, or a simple cotton fabric. Most importantly, as much as possible of the oil composition is applied to the wooden coating..

After the linseed oil has been absorbed, one more layer needs to be applied and thus the steps are repeated until the surface being treated is unable to absorb it.

Next, the product should be dried. To do this, it should be put in a warm dry place. There is no need to use additional heating systems.

Important: sometimes after using the linseed oil, a little impregnation remains, as well as the tools with which it is applied. It should be remembered that the impregnation refers to materials with a high class of fire hazard and any fabric that falls on linseed oil, is prone to fire. Therefore, they must be stored in a well-protected place away from the source of fire.

Drying time

The hardening time of the varnish depends directly on the type of impregnation and the method of its application:

- Small products are soaked in a hot way in a hot water bath - the material being processed is placed in a tank with hot oil for 4-8 hours, and then dried for about 5 days.

- If a little red lead is introduced into such a varnish, the tree will be ready for use much faster - in 2-3 days.

- Oil impregnation with the addition of kerosene dries for about 48-72 hours, but compositions based on linseed oil, turpentine and paraffin will be ready for use after 2 days.

- Drying wax with a wax also dries for about 2 days. In rare cases, it may take 3 days to fully soak and harden.

Tips

When buying a varnish, it is very important to focus on the following points:

- Natural linseed always has a dark brown color, so if you have a clear liquid in front of you, then there is a high probability that it is a composition or simply a fake.

- In the bottle there should not be any suspensions and impurities of foreign substances.

- Pay particular attention to the composition of the proposed product, which is indicated on the label and on the label itself. It must necessarily indicate the manufacturer of drying oil and its coordinates, as well as the used GOST or TU and instructions for use.

- It will not be superfluous to make sure that you have a certificate of conformity and a sanitary-hygienic certificate.

- Keep in mind that composite linseed oil does not dry at all, because it is made from vegetable oils. She will not be able to decorate on paints, nor varnishes.This liquid has a reddish tint.

- The coating applied by the composition based on petroleum resins also has its own characteristics: it either scrubs, or, as in the case with drying oil, does not dry. Such linseed oil is quite cheap and has a light color.

- Learn reviews and professional advice.

How to cook drift yourself, see below.