Quick Step Laminate: Pros and Cons

Quick Step is a well-known brand among flooring materials. He gained his popularity due to his increased strength and resistance to all kinds of environmental influences. The Belgian company Unilin, which is the owner of the Qick Step trademark, is currently among the three largest companies producing floor coverings in terms of laminate production.

The company has specialized in the development of laminated floors for more than a quarter of a century and sells its products not only in Europe, but throughout the world.

Production features

Unilin was founded in 1960, when several family-owned enterprises of the flax industry from south-west Flanders united to begin the production of compressed boards, the raw material for which was a flax fire. But after some time, it was decided to change the type of raw materials and the board began to be made of wood.

In 1990, Unilin was the first in Belgium to begin producing laminate flooring. Engineers of the company owns a palm in the development of a castle system for flooring. The Quick Step era began with laminate flooring "Floating way". Prior to that, they were fixed by the adhesive method.

This unique development allowed Unilin to win a large share in the global market. The company's inventions also include laminate panels with a V-shaped bevel. These floors are very reminiscent of a massive board. In 1997, the company launched a laminate on the market, which in appearance and texture was no different from natural wood. This was another breakthrough, which Quick Step provided leading market positions for a long time.

In Russia, the production of Quick Step laminate began in 2011. The products manufactured here are no different from the European ones, since the plant in the Nizhny Novgorod region uses the same raw materials and materials, the same production lines and a measuring and control system are installed here.

The staff of the Russian plant was trained strictly by the Belgian engineers Unilin. The production process is constantly monitored by the parent company.

In 2005, Quick-Step began to cover laminated panels with an antistatic coating, and in 2007 - launched a series of coatings that can be used in wet rooms. In 2013, a new vinyl coating was introduced to the market, which in appearance was no different from wooden, but at the same time it had all the practical synthetic properties.

The latest innovation was the company Impressive waterproof floor.

The high quality of Quick Step laminate today is achieved due to the following factors:

- Applications of innovative technologies.

- Careful selection of raw materials. Unilin purchases raw material suppliers who supply wood from controlled sources and certified forests.

- Fiberboard, which is the basis for the production of laminate, is made of rubber wood, whose age exceeds 25 years. A rubber tree is used for industrial purposes only when it produces milky sap (that is, in the first 25 years of life). Previously, old trees were cut down. The company Quick Step proposed a new use of this type of wood - for the manufacture of fiberboard.

- Glues and paints used in the manufacture of laminate,the company buys from trusted suppliers whose product quality conforms to European safety standards.

- The use of energy-saving technologies. Quick Step plants are carefully controlling heat consumption. Wood waste is burned in special furnaces that generate heat energy that goes to a new production cycle.

Coating structure

Quick Step laminate flooring has a structure similar to that of other manufacturers. In the production of this coating, a dense fibreboard is used, which is protected on both sides by special coatings that provide all the properties inherent in the Quick Step laminate.

Structure of the Quick Step panel:

- The bottom layer provides moisture resistance and stability of the laminate, it consists of melamine resin. Due to the presence of this layer, the panels are not deformed in the process of laying and subsequent use of the floor.

- The main layer. High density fiberboard, which is made from recycled fibers of rubber wood and melamine resin. Due to the uniform composition and high strength characteristics, this layer provides reliability, stability and moisture resistance of the entire floor covering.

- The decorative layer provides the necessary appearance of the coating with an imitation of the pattern of tile or wood. The image applied to this layer is very accurate; it reproduces the structure of natural materials to the smallest detail due to the high print resolution. Laminate Quick Step in its appearance is no different from this tile or floorboard.

- Topcoat. Provides laminate protection against abrasion, pressure, other mechanical loads, heat and chemicals. This layer of melamine resin is applied to panels under pressure and at high temperatures.

- Sound insulation layer (not available in all models). When laying such laminate does not require the use of the substrate, the panels are mounted directly on the base of the floor.

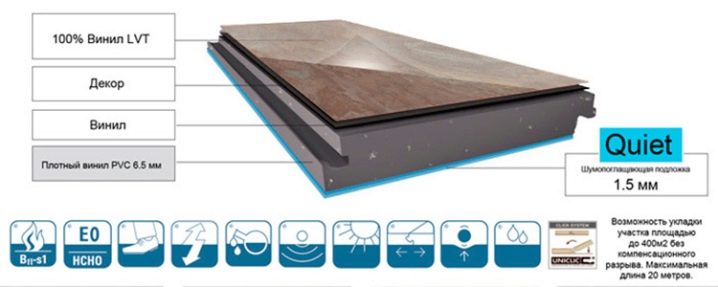

Vinyl laminate has a slightly different structure. It consists of five layers:

- The bottom layer is impact resistant vinyl coating.

- Fiberglass stabilizing layer.

- Shock, soundproof, waterproof vinyl coating.

- The decorative layer providing imitation of this or that natural material.

- Protective overlay.

Advantages and disadvantages

Quick Step laminate is rightfully one of the best flooring. After all, it has several undeniable advantages:

- Resistance to different types of mechanical effects (point, shock, constant) is achieved through the use of high-quality high-density fibreboard, which is produced according to Unilin's own high quality standards.

- Resistant to scratches due to the presence of a special additional layer. This protective coating is applied using a special technology Scratch Guard, which allows you to maintain the original appearance of the laminate for many years. The scratch resistance of Quick Step laminate is 8 times higher than that of other manufacturers of laminated coatings that do not use the above technology.

- A wide range of models. The Quick Step product range varies not only in visual characteristics, but also in functionality and size.

- High levels of light fastness. Laminate Quick Step practically does not fade even with constant exposure to ultraviolet light.

- When walking on the Quick Step floor, there are no unpleasant ringing sounds, since the fiberboard is optimized for a constant load.In addition, when using a special Quick Step substrate, the laminate starts to make a pleasant deep sound, like when walking on a natural wood floor.

- Resistance to short-term exposure to high temperature (for example, when a burning cigarette falls on the floor). A dropped cigarette does not leave marks on the laminate flooring, since it is almost non-flammable.

- Simple installation, accessible even to the non-professional. Thanks to the simple and reliable Uniclic locks, Quick Step laminate is easy and quick to install.

Quick Step floors are well combined with heated floors, you just need to choose the right substrate type and follow the temperature conditions recommended by the laminate manufacturer.

- Water resistant. Quick Step floor coverings are reliably protected from moisture penetration between the panels due to the tight locking system and moisture resistance of the fiberboard. Therefore, accidentally spilled liquid on the floor will not cause any harm to the floor.

- Antistatic coating of laminated panels. Each panel is treated with a special compound that provides an antistatic effect for a long time, thanks to which the floor becomes less dusty and dirty.

- Simple care for floor covering.Since the Quick Step laminate panels are extremely tightly joined, dirt and dust do not get into the joints, which ensures a high level of hygiene of this coating and the possibility of its use in rooms with a constant stay of young children.

- Long warranty for flooring. The manufacturer gives a 20-25 year warranty on their products. And in case of non-intensive use and careful treatment, the floor will last longer. This is due to the use of durable chipboard base, reliable locking system and cover Scratch Guard.

- Ability to eliminate defects. For these purposes, the company has created a special Quick Repair Repair Kit, with which you can easily disguise scratches and other defects. The kit consists of seven colored wax crayons, a brush and a trowel. Colors can be mixed if necessary.

Various collections

Currently, there are thirteen collections of laminated coatings in the Quick Step catalog:

- Arte. This laminate has the shape of large squares with a V-shaped bevel with imitation of marble, leather or Versailles tiles. Such panels are the ideal choice when creating original floors in the style of past centuries.Such coatings combine the reliability and attractiveness of this floor with the functionality and convenience of the laminate.

- Classic. As the name itself says, this is a covering in the form of standard panels with a pattern resembling a slatted parquet of multi-colored dies. Some models mimic the coating of the rails of different heights.

Such a floor is no different from the real parquet made of oak, beech or cherry and it looks especially realistic.

- Creo. Laminate without chamfer. In this collection, designers especially successfully managed to emphasize the unique character of each type of wood.

- Desire. The metallic luster of the models in this collection emphasizes the structure of oak laminated floors in a special way.

- Eligna. The floors from this collection resemble a natural wooden floor made of walnut, oak, ash, wenge and merbau. The special beauty of this laminate is achieved due to the optimum ratio of the width and length of the panels. The slats have an elongated format and are the epitome of refined taste and refinement.

- Eligna wide. This is a kind of addition to the previous collection. Models of this series have an increased width of the panels, which makes it possible to more fully reflect the beauty of rustic decors.

- Exquisa. Innovative series, represented by laminated panels, imitating tile. At the same time, this laminate has a relief surface with transverse stripes-grooves, resembling the jointing between the floor tiles.

- Impressive. Laminate with a water-repellent coating and pronounced joints between the panels. Thanks to HydroSeal, this type of floor has the highest moisture resistance today.

- Impressive Ultra. The collection of moisture-resistant and wear-resistant floors of medium format with a natural wood pattern.

- Magestic. With the help of laminated panels from this collection, you can create unique stately interiors. This is facilitated by the increased size of the slats and the natural pattern on them. The coating has a high moisture resistance.

- Perspective. The use of such panels in the interior allows you to visually expand the space due to the ideally chosen size of the slats and deep straight chamfers.

- Perspective Wide. Panels with an increased width allow you to fully reveal the originality of woody ornaments.

- Rustic The narrow laminated panels in country style with chamfers and relief structure.

Unilin cares about its customers and it doesn’t care what the floor will look like from its materials. Therefore, it specifically produces related materials for laying floors. For each model of the cover, designers have developed their own set of thresholds, thresholds and baseboards in the color corresponding to the main cover.

Colors

The color palette of Quick Step laminate floors is presented mainly in soothing natural shades:

- Arte: marble tile, under the skin - light and dark, Versailles white oiled, dark and light.

- Classic: Classic collection in beige-gray-brown colors (light gray and gray antique oak board, moon oak, royal oak, cuban oak, light charlotte oak, dark old oak, bleached oak, selected merbau, dark oak board of dark natures and dark , board ash American).

- Creo. Collection in silvery and golden oak shades from ashy to black.

- Eligna. The collection is represented by exquisite warm shades (old beige oak, white ash, oiled chocolate oak, natural oiled warm oak, oiled warm gray oak).

- Exquisa - tile in gray-beige tones.

- Impressive - a series in earth tones from fantasy white oak to oak, black night (smoky oak, sand oak, southern oak, bordeaux oak, pine).

- Magestic. Collection in warm shades of oak.

- Perspective. A series in natural colors from pine snowy white wiped to wenge.

- Rustic These are predominantly saturated natural colors (walnut Pacific, hickory coffee, dark white oak).

Styling and care

Before you install the Quick Step flooring, you should carefully prepare:

- First, acclimatize the laminate in the conditions where it will fit within 2-7 days.

- Secondly, disassemble the old floor covering.

- Thirdly, make sure that the floor is flat, clean, dry and free from mold and insects.

Further:

- Before laying the laminated floor, you need to mix all the panels so that in one place the floor is not too dark or too light.

- Laminate will look best if it is laid along the longest wall and in the direction of light falling from the window.

- Under the laminate should lay a special substrate Quick Step.

- The first row usually starts with a whole panel, after having cut a comb from it with a short and long side.Between the wall and the panels leave a compensatory seam up to 10 mm wide.

- Perhaps at the end of the series will not have to lay the whole panel. In such cases, the laminate is trimmed, and the next row starts with trimming. At the same time, the joints should be staggered. To lay the second and subsequent rows, you need to take the panel and place it at an angle to the previous row (20-30 degrees) and begin to gently move from top to bottom, applying a little effort until the panels click.

- After laying several rows, open packaging with laminate is put on the laid rows and, going to the laid laminate, insert the short side of the plank into the previous strip until it clicks. Then both hands are placed near the junction and the long side of the panel is pulled towards itself. The lock snaps into place.

- Further, the installation continues in the same way until they reach the opposite side of the room.

- Dry cleaning of floors is carried out with a vacuum cleaner or a special Quick Step mop. In this case, the vacuum cleaner must have soft wheels and a brush for cleaning the flooring.

- You can use a steam cleaner to care for Majestic and Impressive floors.

- Wet cleaning of floors is performed using the Quick Step kit.

- Puddles from the floor must be cleaned during the day from the moment of their appearance. From the floor of Eligna, water should be removed within an hour.

- To avoid scratching, furniture legs should be protected. To avoid sand, dirt and moisture on the floor by the door should be put a rug.

- Do not use abrasives to remove stubborn stains from the floor. This can be neatly done with acetone containing agents.

How to choose?

If the buyer chose the Quick Step flooring, then most likely he will not be disappointed. After all, according to reviews of this laminate there are practically no flaws.

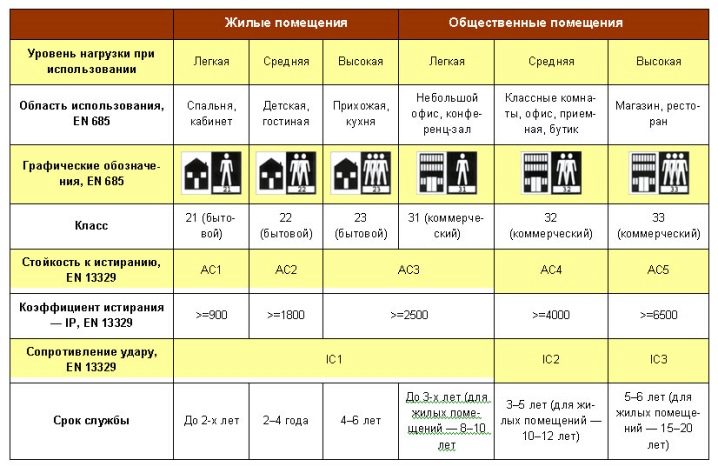

Since virtually all collections of Quick Step floor coverings have 32nd wear class, then the selection process is reduced only to determining what the appearance of the floor should have. And for this you just need to go to the manufacturer's website. look through their catalog or look into the store.

Laminate 32 class is suitable for commercial use, and, therefore, when installing it in a residential area, its strength will be enough for many years. In addition, Unilin has increased requirements for its coverage, and their 32nd class can be compared with the 33 class laminate produced by other companies.

But, nevertheless, Quick Step quite recently introduced in its range a coating of 33 classes with a thickness of 12 mm. This is a laminated high-strength coating for rooms where there is a constant high humidity. But the price of this product is quite high, although it justifies its quality.

Sometimes when finishing the premises there is a need to arrange the steps of the laminated floor. When choosing Quick Step, this problem does not occur. For these purposes, the company has developed a special profile. Quick Step Incizo. Using the cutter included in the kit, you can easily change the profile configuration. The profile is easily matched to the color of the laminate and is suitable for any type of stairs: old and new, outside, straight and with a platform.

How to lay Quick Step laminate, see below.