Choosing a substrate for laminate: characteristics and recommendations

During repair, laying flooring is of great importance. After all, the comfort of people living in the house will depend on this. When choosing a laminate, it is necessary to take into account all its pros and cons, and before laying it is important to determine the choice of substrate. About this in detail and tell in the article.

Why do you need?

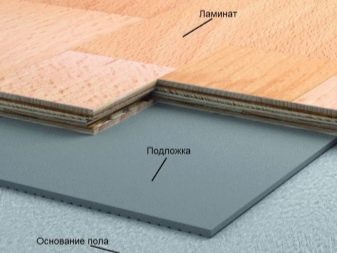

To begin with, it is worth saying that laminate flooring is one of those floor coverings that are made of wood materials. The disadvantages of such a coating are moisture intolerance, deformation due to temperature difference, large porosity. In order to provide the coating with reliable protection, various substrates and insulated compounds are used.

They fit on the basis of the floor. Also, the substrate can extend the service life of the vinyl laminate, so it is worth a responsible approach to its choice.It is not recommended to lay the laminate on the "bare" base without a special lining.

The lining is primarily used for additional strength of the flooring, as well as to distribute the load on the floor evenly. If the lining is not, then the coating will quickly deteriorate and become unusable.

Another feature of the substrate is soundproofing. Incorrectly laid laminate can creak and transmit the sound of steps, this may be due to the thickness of the panel. Usually its thickness is 8 mm. But even with this size, the laminate can withstand heavy loads. This problem can be solved by laying an additional lining, which has good sound insulation.

Some manufacturers equip laminate with a special substrate, sticking it onto the reverse side of the boards. This laminate is not common, as the price is quite high.

Therefore, in order to save, you can purchase the substrate separately, so that it possesses those characteristics that will suit you the most.

Additionally the lining can perform leveling function. It smoothes irregularities that are present on the concrete screed. Any small deviations after some time can adversely affect the laminate. Any irregularities and ground drops can affect the formation of backlash between the panels and the concrete screed. In simple terms, the coating will sag in those places where the gap is extremely large.

At first glance, this problem may seem insignificant, but later the backlash will be very noticeable on the floor surface, especially when walking.

Another important function of the lining is waterproofing, as the laminate, and many floor coverings, poorly tolerate moisture. In this case, the lining implements a waterproof function, maintaining a suitable microclimate for both the concrete base and the back side of the floor covering.

But first you need to take care of the safety of the coating, before repairs will be carried out. First of all, the prepared base for laying laminate should dry well. Often this process takes about a month.Therefore, it is not recommended to hurry with the laying of the laminate, otherwise condensate will accumulate between the dry surface and the floor covering.

The soundproofing function of the lining protects you from various sounds. Having laid a high-quality lining with a foil layer, you can avoid the appearance of squeaks laminate boards.

The vapor barrier function is necessary to prevent excess moisture and fumes from accumulating under the surface. If you lay the substrate with a foil layer, you will be able to protect the laminate from their negative impact. Such a lining ensures your durability and saves money.

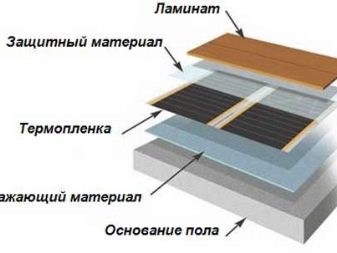

The heat-conducting function is another characteristic that the lining must meet, especially if you plan to install the “Warm Floor” system. With this heating function, the heat will always spread evenly over the floor covering. In this case, the concrete base will not be heated.

Kinds

A mandatory step in the repair is laying under the laminate special lining. Therefore, before buying is to know all its advantages and disadvantages,so as not to face the problem of poor-quality paving.

Before laying the coating, pay attention to the condition of the concrete screed, prepared as a base. If the surface is smooth, then a substrate 3 mm thick will fit perfectly. And if the base with small irregularities, it is better to align, using a lining thickness of 5 mm.

Most manufacturers advise laying the lining of the same company as the floor covering. But in fact, it does not matter much, so any absolutely high-quality material will be suitable.

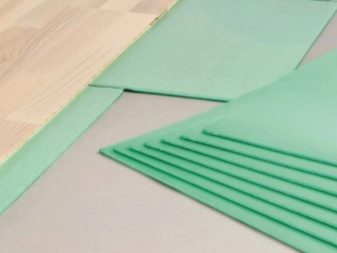

To date, among the most famous varieties of linings under the laminate can be distinguished polyethylene foam, polystyrene foam, combined, coniferous, as well as cork and bituminous. Lining can also be divided into types. Sheet lining is made in the form of sheets.

Suitable for rooms of all sizes, easy to install. Usually, in this form, linings are made of natural materials, which are not harmful and do not accumulate condensate, are non-combustible and moisture-resistant, warm up well and breathe. Wherein the sheet linings have a rigid base that does not lash and withstand heavy loads.

Rolled linings are produced by most manufacturers.They have a low cost, compared with sheet linings, they are not afraid of temperature drops, cold air and moisture, and they are not prone to rotting. The only downside is that they are not suitable for high-traffic areas, as they are able to quickly disinfect.

Lined "accordion" is a sheet, fastened together. It is very easy to fit due to its shape.

Corkboard

Cork lining can be in the form of rolls and in the form of sheets. It is also available with a metallized top layer. It has certain advantages over other materials: high thermal insulation and sound insulation, resistance to decay, mold, the ability to use with the system "warm floor" and "floating" floors.

Cork lining under the laminate perfectly copes with the functions assigned to it. The main disadvantage of cork lining under the laminate is its cost, especially if it is laying a cheap coating with a short lifespan. Also, this material is characterized by the appearance of condensation on the back side of the floor covering.This may be bad for his condition.

Polyethylene (izolonovaya)

Thanks to such indicators as thermal insulation and moisture resistance, polyethylene foam lining has long been very popular in the construction market. Its synthetic structure is able to provide protection against penetration of pests, insects and rodents under the floor covering. It is very easy to install and install the plastic lining.

Some manufacturers produce such linings with an additional top layer of foil. But the service life of this material is only a few years, which will be unprofitable for the buyer. After all, over time, he quickly proyadet and become useless.

Isoplat substrates are 4 and 8 mm thick. They are specially manufactured for flooring as well as for repairing old floors. This may be a concrete screed or wooden floors. Isoplat corrects irregularities of such surfaces, insulates them, provides high sound insulation and moisture resistance.

Polyurethane linings and foamed polypropylene have the same properties. The main disadvantage of these materials is non-ecological.

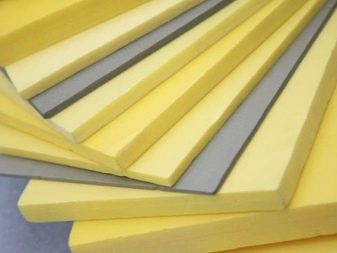

Polystyrene foam

Such a lining under the laminate is one of the most popular. It has good resistance to heavy loads. This material is good for rooms with a large cross, as it does not promin. More polystyrene lining is able to align the concrete surface of the base.

Styrofoam is a material with high elasticity, so its thickness will be maintained for a long time. Besides, it is able to absorb vibrations when walkingmaking the laminate more noiseless. Its special structure does not allow moisture and does not allow condensation to form on the surface of the coating.

This material has a high quality, it is available and costs the buyer very cheap, but its main disadvantage is not environmentally friendly composition.

Extruded polystyrene, or polyfoam, differs from polystyrene foam material by a special production technology. It is called extrusion and allows flooring to acquire special qualities due to the conversion of the polymer. Its cells provide high sound insulation properties.Extruded polystyrene is usually produced in the form of plates with special markings, which will help to easily install the material on the surface of the base.

This material has good moisture resistance, so there will be no risk that the laminate will not swell and deform. The composition of such material resists bacteria, and is also resistant to caustic aggressive substances, while it does not rot and does not become covered with mold.

Another type of laminate flooring is foam lining. This material is characterized by good thermal insulation properties, but the main disadvantage is that Foam lining is not suitable for residential use. Also at frequent loads, the lining is rapidly pressed.

Conifer

As mentioned earlier, many materials are not environmentally friendly, but, nevertheless, there are exceptions among them. For example, leaf coniferous substrate under the laminate, which is made of wood fiber. It is also called spruce, as it is made from pressed needles of spruce. Its porous structure has good sound insulation and has the function of air circulation, which will ensure the coating a long service life.

Laying coniferous litter will not cause great difficulties, even for a person who is laying the cover for the first time. After using it reviews of satisfied buyers who provided their homes reliable and eco-friendly floorconfirm this.

The only disadvantage is the high cost of the material.

Metallized

This gasket consists of two layers - izolona or polystyrene, as well as foil layer. The thickness of this insulation is not more than 5 mm. Metallic lining can be used in a low temperature room. The foil coating increases thermal insulation and resistance to temperature changes, and the polystyrene layer provides good sound insulation in the room.

This material has a high moisture resistance, so you do not have to lay an extra layer of plastic film. Metallic lining reliably protects the floor from the penetration of various fungi and mold.

The material is used in the repair of the floor in those rooms where there is a high risk of moisture penetration into the concrete screed. This could include a bathroom, toilet, kitchen and basement.Before choosing a substrate for laminate, it is necessary to consider its thickness.

It can reach up to 10 mm. The thickness chosen depends on the type of flooring and the level of floor drops. It is also necessary to take into account the fact that foamed polyethylene can sieve with time, therefore, if the lining thickness is chosen incorrectly, the quality of the installation of the laminate and the period of its use decrease. To install under the laminate you need to buy a lining with a layer thickness of up to 2 mm.

Other options

The rubber lining is an integrated material, as it is immediately glued to the laminate during its manufacture. The rubber coating has a thin protective layer of a special material that can increase the shelf life of the lining. Rubber is one of durable materials that does not deform over time, and also does not deteriorate when exposed to moisture and water.

Its sound insulation is at a high level, so it is able to absorb various noises and vibrations when walking on the laminate. The only disadvantage of this material is the high cost.

The bitumen lining is made using special raw materials.Bitumen is applied to dense Kraft paper, which acts as the underside of the lining. This material is very durable and resistant to moisture. Parts of this lining dock with each other without overlap and are fastened with adhesive tape.

Jute substrate is different in that it is made from non-woven cloth, which contains plant fibers in its composition. Its production occurs at high temperature by punching the fibers, which are fixed together. Thus fabric is formed, which is characterized by high strength and elasticity. To the material was resistant to decay, it is treated with a special tool.

Although the jute lining easily absorbs moisture, it does not deform and takes on its original appearance when dry.

Heat - it is one of the modern insulation materials, which has the best thermal and sound insulation. It is widely used for insulation and sound insulation of floors.

Rubber lining is made of cork and rubber. This combination provides this material with high waterproofing. It is packaged and sold, as a rule, in rolls.

Felt insulation is made of wool by felting. It turns out it is very dense, as wool fibers are treated with steam and special means that protect the felt insulation from fire and rotting. Its main advantages are environmental friendliness, good heat-conducting ability, abrasion resistance.

Plywood is one of natural materials that is ideal for laminate or other flooring. It withstands heavy loads, evens out uneven floors and is an affordable material.

Fiberboard is also suitable as a substrate for laminate. This material is made of wood fiber. Fiberboard is a natural material, as well as a bamboo backing or plywood. Its main advantage is that it does not emit volatile chemical compounds.

Combined types

The composition of the lining of the combined type is the synthesis of various materials, for example, polyethylene or polystyrene foam. The most famous such lining produced by the brand "Tuplex". Its main feature is that it has two layers of polyethylene, between which there is one layer of balls from expanded polystyrene. This structure able to provide good air circulation. The thickness of the substrate is about 3 mm.

It is sold, as a rule, in rolls. It is possible to enclose this material on any basis, since it does not let in moisture, it has high strength and the ability to smooth out the defects of the base. Tuplex well bends and maintains thickness throughout the entire operation.

Which is better?

To decide which substrate for laminate is best suited, first of all you need to pay attention to its technical characteristics and quality. Today there is a wide variety of assortment, so making the choice is not easy.

The substrate for laminate should have a long service life, because you will use it for many years. If you take a parameter such as thickness, then it is not recommended to use too dense liningotherwise it will quickly come and ruin the floor.

If you decide to install a "warm" floor, then under it you will need to lay a perforated insulation, as it will be able to provide high heat transfer.

It should be noted that it is also necessary to pay attention to the following criteria: insensitivity to aggressive substances or materials; Availabilityantiseptic treatments; thermal conductivity and moisture resistance; the presence of protection from insects and rodents; high strength and durability.

You also need to know that high-quality lining allows you to increase the life of the laminate.

Which one to choose?

To make the right choice, when buying a lining under the laminate must take into account all the advantages and disadvantages of this material. It should be said that it is not difficult to put it, but it should be done only on a flat surface, otherwise the floor will quickly become unusable.

The lining must have a high thermal conductivity, sound insulation, vapor permeability, resistance to mechanical stress, and the seller must have a certificate of conformity. If you compare customer reviews, it is worth saying that inexpensive materials are the most popular, but they have an unnatural composition, which makes them less environmentally friendly.

On concrete

Concrete is one of those materials that does not retain heat and at the same time forms condensate. Even with good processing, it is difficult to keep its surface smooth.For such a base suitable lining, which will have high thermal insulation properties and protect the floor from temperature differences.

Types of substrates can be different, both from artificial materials and from natural ones. Perfectly suitable polyethylene foam, polystyrene, as well as cork and pine. It will not be superfluous if the basis to make in advance equal, dry and pure.

On a wooden base

For wooden flooring, those substrates that have good vapor permeability are best suited. This can be explained by the fact that wood is a natural material that must "breathe." Otherwise, the wooden base can quickly rot and deteriorate.

For such a base, cork, softwood or composite materials, bitumen cork material, polyethylene foam and polyurethane foam are best suited.

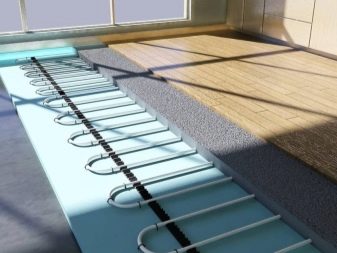

On the "warm floor"

Before you go to the flooring, you need to figure out which lining fits the laminate flooring on the “warm floor”. First of all, it should not change its shape under the influence of heat and not emit harmful chemicals into the air, that is, it must be heat insulating,and also be able to microcirculate air.

It is recommended to use material made of polystyrene. "Tuplex" or foamed polyethylene. But the most environmentally friendly option would be cork substrate.

Also, when choosing a lining under the laminate, pay attention to the special marking, which will indicate whether it is suitable for floor heating.

Options

The dimensions of the substrate are varied. Its main qualities depend on it. For example, a thick lining has good noise insulation and provides high protection for the flooring. But such material is better to use as intended. After all, it can quickly shrink, and the laminate and its interlocking compounds deteriorate.

Typically, the thickness of the substrate under the laminate varies from 3 mm and 10 mm. The best option would be a thickness of 5 mm or 2 mm. Natural substrates usually have a large width, and those made from artificial materials are usually very thin. They are ideal for a flat floor, in which the height difference is not more than 3 mm.

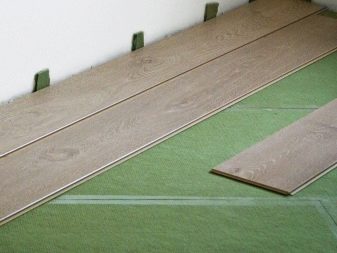

Piling

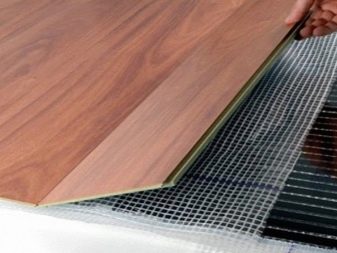

In order to properly select and lay the substrate in the apartment, it is not necessary to have professional skills.You can do the job and do it yourself. Just need to follow certain rules. The main point in laying the substrate is its location. First, the substrate must be laid under the laminate in the opposite direction, as with careless movement of the floor may move. Secondly, the substrate should start on the wall.

To ensure that the coating lasts as long as possible, do not use a damaged or damaged substrate, but replace it immediately with a whole. It is recommended to lay the substrate across the laminate, because it does not happen overlap joints and panels of the laminate.

Otherwise, the boards will sag, thereby reducing the service life of the coating. Another important point is which side to lay the lining. It all depends on the type of material. If it is a embossed film, then lay it ribbed side down. And the material from the foil base should be placed on top.

But you must first level the surfaceon which the substrate will travel. In order to provide a good vapor barrier coating, you will need a dense polyethylene, the sheets of which are attached overlapping each other with adhesive tape.A film that is adhered securely in this way prevents moisture from penetrating.

The rolled substrate must be laid along the longest side of the room. Sheet fit on the entire surface of the room.

It is important to know that you need to lay the material in one layer. If you put a double layer under the laminate, it will quickly deteriorate and be pressed through.

In the next video you will find a review of the substrate under the laminate.