Laminate features 32 classes: characteristics

When they call a class of laminate, mean its durability. It is believed that the higher the class, the longer the coverage will serve, but in reality it is an indicator of what maximum loads it can experience without losing its presentation. If you do not take digital symbols, the manufacturers divide their products into household, semi-commercial and commercial. There is still an additional view for special institutions: airports, sports complexes, hospitals. The most popular among consumers - 32 grade laminate.

What does it mean?

Wear resistance is the ability of a material to resist wear, that is, not to change its structure under the influence of sunlight, loads, temperature drops and another for a long time. The concept of wear resistance of a laminate also includes:

- its robustness, that is, it must withstand high type loads at any temperature declared by the manufacturer, including a high resistance to friction;

- back-up robotic capacity, that is, when the frame leaves the permissible temperatures upwards or downwards or when the load on the floor increases (throughput increases) the laminate must not lose its characteristics for some additional time;

- degree of wear, which, under the specified operating conditions, should be carried out so that only the smallest particles of material are separated from the surface.

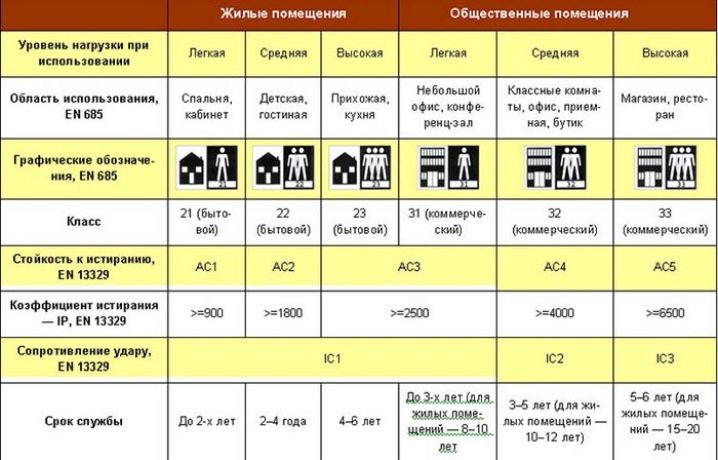

Laminate 32 class refers to commercial flooring that is suitable for home use. This is the optimal combination of wear resistance and cost of material for laying in residential areas with increased loads: where there are children, pets or a large family lives.

Specifications

Before assigning a product to a particular class, the manufacturer must test all its technical characteristics:

- The life of the laminate class 32 for household use 10-12 years.

- Resistance to abrasion involves checking the coating for resistance to friction. Friction means the contact of the surface with the feet of people barefoot and in shoes, as well as movement on the covering of wheelchairs, bicycles, wheels of office furniture and other items. Marking is not lower than AC4. Ratio ≥ 4000.

- Resistance to prolonged stress. By this is meant a static load in the form of a long stay on the floor of heavy things, for example, wooden or metal furniture.

- Tolerance to high temperatures. The resistance of the laminate to fire. Also, this includes long-term operation at high temperatures, the maximum allowable for 32 grade of coating.

Impact resistance determines the resistance of the laminate to the fall of heavy things on it from a height of at least one and a half meters. That is, a hammer that fell from the cabinet should not leave a hole on the laminate. IC2 marking.

The following tests are applied to the laminate:

- Delamination test is carried out in order to understand how strongly the top layer of the coating can separate out with strong differences in temperature and humidity.

- Resistance to fading determined by the ability of the coating to not change its color under the influence of direct sunlight. There are four types of resistance to the sun: sufficient (for rooms facing north), relative (suitable for use in cloudy climates), good (can be used in rooms facing the sunny side) and high (laminate with a protective impregnation for hot climates and rooms facing south). 32 class always has good resistance to UV rays.

- Chemical resistance test. The test involves washing the laminate rather aggressive means, including abrasive. In this case, is closely related to the value of abrasion.

- Swelling test from the absorbed water laminate 32 levels goes perfectly. The entire coating can be removed in a wet way and not be afraid that it will swell from moisture. For those who want to put the laminate in the bathroom or kitchen, there is an additional impregnation from moisture.

Dimensions

Laminate consists of several layers of fiberboard, the top of which is covered with a decorative film with a wear-resistant factor. The thickness of the board can vary from 6 mm to 102 mm, but the standard thickness is 8 and 10 mm.The thicker the board, the less traces of furniture remain on it, more warmth holds, less deviation in the trapezoid and easier styling.

The width of the board starts from 9 cm, if the laminate is supposed to imitate ceramic tiles, the width increases to 33 cm. The standard size of the slat width is 18.5 and 19.5 cm, it’s not just that, the optimum ratio of ease of installation and appearance is achieved with these sizes "Wooden" boards.

The length of the lamella can vary from 126 to 138 cm. There is an option with a length of 184.5 cm, but it is more difficult to stack. The floor under it must be leveled perfectly, and the room length must be at least 10 meters.

A package usually contains 8 boards, sometimes it is 5 or 6. A package weighs 17.4 kg.

Manufacturers

Each manufacturer has differences in the classification of laminate. And if one laminate falls into the 32nd category, then the other one can consider this coating to be domestic. If you buy Austrian, Belgian, Polish, German laminate, then focus on the durability indicators of the AU, they will meet international standards (AC4 for commercial flooring). For Chinese coating class is not an indicator, in the commercial standard of 32 classes they can get material with AC2 coefficient. Russia is focused on the European system.

Germany became the first to produce coatings with green bases and locks, among the population is firmly established that this laminate is of increased strength and is not afraid of moisture. In fact, it was a marketing ploy of a manufacturing company that simply wanted to protect its products from fakes. This was a bet in Asian countries and Chinese laminate is often produced with a green substrate. This product has nothing to do with moisture resistance.

Swedish laminate Pergo characterized by the presence of silver ions in the upper layer, which very well create an antimicrobial barrier and dissipate static electricity. In addition, the density of the plate is more than 800 kg / m3. This causes ease of care. The strength of the protective layer guarantees 25 years of service due to special surface treatment.

Berry-alloc has a large number of collections. Each collection has a huge number of models in the design from classic to extravagant design. In addition, this coating has increased noise insulation from impact noise.

Reviews show that in the top European manufacturers is Balterio. They produce a coating with 100% imitation of wood, boards can have several types of chamfers, the size of the board is presented in five variants, and its density starts at 865 kg / m3 (the board itself produces the boards). The moisture resistance of products reaches 10%, and the service life is 30 years.

How to care?

It is easy to care for laminate, the main thing is to follow two important rules - to remove sand from the surface in time so that it does not scratch the coating once again and try not to pour a lot of water on it during cleaning.

The main cleaning method is a vacuum cleaner with a turbo nozzle or a nozzle for collecting wool. Even if you are used to carrying out dry cleaning of the bare floor, removing the bristles of the brush inside (as shown in the instructions for the vacuum cleaner), then it is better to release it - put in the mode of cleaning carpets.

It is desirable to wash the floor with water and only once a month with the help of special tools that are made on the basis of organic soap. The floor after them shines, does not slip and the coating does not deteriorate due to aggressive impact. When choosing a product, keep in mind that excess glycerol harms the seams of the coating. He penetrates the locks and swells them up. If you are allergic to household chemicals, then use 9% vinegar at the rate of 1 tablespoon per 10 liters of water. True, the special tool is designed to remove almost all household pollution, vinegar will only give a certain shine. To prevent the penetration of moisture between the lamellae, you can use sealant for the joints.

Stains from the coating should be removed immediately. Wine stains are removed with soapy water, and juice and grease stains are removed with shampoo or shower gel, by means that contain a neutral pH factor. Persistent dirt such as a marker, felt-tip pen, or a pencil trace can be removed with solvent on acetone diluted according to the following scheme: 1 teaspoon of a substance for 2 tablespoons of water. After that, the place of exposure to alcohol should be washed with water and wash the entire floor with a solution of vinegar to even the entire surface in terms of gloss.

You can not wash the coating with hot water, because of it there is a distortion of the surface, and in any case do not use the means to care for the flooring. Beeswax in their composition completely destroys the protective layer.

To eliminate quite serious damage - chips and scratches,it is better to purchase a repair kit, which includes a wax crayon of a certain color (for minor damages) or a special paste with a spatula. For the selection of funds for color it is better to have a sample.

Wax chalk rubbed over small scratches. To do this, degrease the surface with methyl alcohol, wipe it with a damp, clean cloth, allow it to dry completely and rub it into the damaged area with pressure. After hardening the paste, the surface is polished with a dry, lint-free cloth.

Working with tinting paste involves heating it, applying it to the surface with a small spatula, and removing excess paste with a damp cloth. Full surface polishing after drying.

In addition, each housewife has his own recipe for washing laminate floors. Someone washes away the eaten dirt with oven gel, having previously tested its effect on the coating on a piece of the board or in a place invisible to the eyes. Someone completely abandoned household chemicals, including specialized, and washes the floors simply with water without means in two stages: the first time washing off the dirt, the second - wiping dry with a foam pad.Someone softens the water for washing with a teaspoon of a fabric softener for 10 liters of water, and there are no stains on the floor.

Popular colors and design in the interior

The most popular colors in this season, as before, are bleached oak and wenge, they suit all types of interiors, ranging from a room that is too light to a room in gloomy colors.

However, many buyers now prefer with a cool design of walls and textiles to make the floor a warm shade. A pear or natural oak tree is best for this purpose. A similar decision makes a certain piquancy in the interior.

The originality of the coating of any color gives a V-shaped chamfer on the edges of the board. It creates a relief effect and refracts light in a different way, which makes it possible to achieve an interesting transition of tones.

About what is the difference between 32 and 33 class of laminate, see the following video.