Slab fence: a budget option for the fence

The fence, made of slabs, is among the most cost-effective and practical types of wooden fences. It can be made on its own without any technological frills, as well as without hiring specialists and paying for their services.

Material for such a fence can be obtained without problems on any sawmill, if not for nothing, then for very little money. The fence of this type is distinguished by reliability and durability, and with appropriate diligence it can be given the necessary beauty and unusual appearance.

What it is?

The croaker is nothing more than a waste from sawing wood trunks in the woodworking industry. When a log in a sawmill is sawn into boards of various thicknesses, lateral fragments of tree trunks become waste from such a process. They have a rounded shape on one side. These side parts are called crooks.To this day they are purchased for firewood where there is no gas heating, due to their low cost.

The croaker should be distinguished from unedged boards. Unedged board is flat on both sides. It differs from an ordinary board by the presence of raw edges. This type of wood material at a price significantly lower than the semicircular cropping-slabs, sold at low cost as waste wood processing.

The croaker looks like a sawn sawn from one side only. Another part of it preserves its natural appearance and the appearance of untreated wood. In the past, it was used only as fuel and as a finishing material for temporary and rough fences, buildings and other structures. Summer residents, having appreciated the advantages of this timber, later began to build from it reliable and distinctive fences.

The cost of it, as already mentioned, is very small, and all its variants depend on the type of wood, the method of processing wood and the dimensions of the slab.

Advantages and disadvantages

The croaker as the “fence” material is chosen by the owners of villas and private households in rural areas, primarily because of its availability and low cost.Given the fact that the fence is supposed to be constructed independently, its total cost will consist only of the cost of purchasing and delivering the material to the work site, plus a small amount for nails.

Fences made of it are easy to install, reliable and durable. These structures are very resistant to atmospheric factors, and in the presence of imagination and taste they can be given a rather aesthetic appearance. These fences, naturalistic and universal in their purpose, are distinguished by originality and originality of the exterior.

Fences from the slab have a significant weight, as well as a long service life. With proper material processing, such a product can last for 15–20 years.. The simplicity of their installation allows you to create such facilities with your own forces together with one or two assistants to any owner of a summer house or a private household.

This also includes the environmental component. The natural material from which such fences are made cannot simply release anything toxic to the environment. In addition, their natural appearance and the pleasant smell of wood can not but rejoice the owners and their surroundings.

Such fences are of no interest to vandals.Slab can not be passed for scrap or sell.

Even for the rapid construction of temporary fences or sheds, it is difficult to find more suitable timber than a slab.

Its advantages also depend on the type of wood that was cut at the sawmill. In terms of hardness and durability, primacy should be given to oak, beech, and larch trunks, and then coniferous woods and aspen. For the construction of the most commonly used timber coniferous trees.

However, the slab has its drawbacks. Due to the unsightly appearance of this material, its enrichment requires considerable time and labor costs, because you need to process and sand each plate. In addition, you should choose the required number of dies with relatively even sides, having also approximately the same width.

The construction of the fence from the slab will require a large amount of this material due to the need for its selection.

After installation, the slab must be treated with antiseptics several times, otherwise its useful life will be reduced to 3-5 years.

The whole process of preliminary preparation of slab strips is extremely tame, that is extremely time consuming.

Although this lumber is notable for its availability and cheapness, it will take a lot of time and effort to build a decent fence from it, but the result of such work will be as aesthetic and original fence as it is desirable for its owners.

How to choose?

This lumber is divided into two types - business and wood.

- Firewood can not be used in the construction of wooden structures due to the heterogeneity of its surface and the fact that it is obtained from cutting trees of non-solid species.

- The business slab goes to the sheds lining, formwork and outbuildings, fencing and various partitions are constructed from it. This type of slab is usually divided further into thick and thin. This lumber stacked in bundles is more expensive than just dumped in a pile, because such bundles contain less waste. These packs contain pre-sorted wood.

- The best grade of this timber is its calibrated variety or block house.It costs ten times as much as an ordinary business slab, but also requires pre-treatment for bark removal and polishing.

- An ungraved slab is especially textured, but with time the bark exfoliates from it, and bark beetles can appear in it. After barking and polishing, this material takes on an expensive and noble look. After treatment with protective antiseptic impregnation, its service life reaches 20-25 years. Slab grinding services are provided by sawmills for an extra fee, but you can do this work yourself with a grinder and an ax.

There is no particular difference in the selection by breed, but it is better to abandon the poplar, because it rots, and from the birch, because its wood is very hard and warps over time.

It should be borne in mind that after the material has been delivered to the site, it must be sorted and processed in a short time. This is done so that the bark beetle does not cause the material to become unusable. It is also recommended to dry the plates.

The cheaper the slab will be chosen, the more it will have defects in the form of irregularities, knots and the like.

If wet lumber is purchased, it should be dried not in direct sunlight, but in a shady place open to air, otherwise it will dry out intensively and its surface will be covered with deep cracks.

Should not give priority to the croaker with a width of more than 20-25 cm. On such wood, over time, large horizontal cracks appear over the entire length of the scaffold.

If it is planned to nail the slab horizontally, then for this should not select too narrow boardsotherwise the fence will lose in aesthetics.

You should know that after some time the slab narrows by 1.5-2 cm due to the drying out of the wood. Therefore, its installation should be done overlap.

If you put a solid picket fence, devoid of gaps, then you need to take it for slabs, having a smooth edge, otherwise you will have to finish them with a plane or an ax.

A fence that has gaps can also be made from uneven material. The main thing here is the correct layout of the boards..

The best option would be thick and wide chopping slab. Some of them can give quite a normal bar for the pillars, if cut them along the length.

It is better to refrain from buying lumber from trees that were cut in the warm season and lay for a long time outdoors.

Under a layer of bark on the wood of such a croaker, there is often damage by mold and pest beetles. But in winter, the purchase of stale wood will not cause problems, because the fungus and the bark beetle do not show activity in the cold.

It is undesirable to purchase frankly raw wood., as it dries out, it starts to warp and crack, which negatively affects the appearance of the structure.

Too narrow a material of small thickness is also undesirable to buy. To create a picket fence, you need a lot of narrow boards, and it is inconvenient and time consuming to engage in removing the bark from thin fragments.

Being engaged in the choice of timber at a woodworking enterprise, it is better to spend time on a sample of slabs to select the most appropriate specimens. This significantly saves time and labor costs in the manufacture of the fence.

Timber on poles

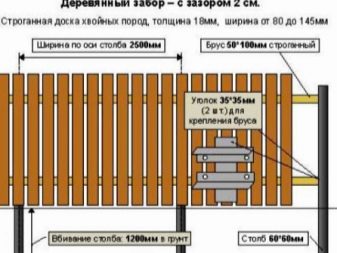

For the support pillars of the temporary fence it is quite acceptable to nail two slabs with nails. If the structure is planned to be operated for a long time, about 15–20 years, a 10x10 cm section timber or round timber of ø 80–100 mm should be used for the posts.On the crossbar, you can use thick blanks or apply a timber section of 60x40 mm.

If it is decided to build a more solid fence, having a height of up to 2.5 m, then the supports should be made of metal pipe.

For a solid fence, the size of such a support is 40x60 mm, and for a lighter fence with clearances it will be equal to 40x40 mm.

Hedging options

The simplest option for execution is a vertical fence or paling. In this case, the frame is made in advance, and dies of the croaker are vertically nailed to it.

In the second case, it is a horizontal fence, devoid of crossbars. Stuffing slab is made in the horizontal plane from one pillar to another butt dies: with gaps between them or overlap.

Another type is double-sided fence. In it installation of not cut board is carried out from two parties of a fence.

This option is the most expensive, since it requires twice the amount of lumber.

Calculation of material requirements

Usually, the owners of dacha plots and private households build a solid fence up to 2 m high from the croaker to exclude the possibility of looking at them on the territory.Vertical installation of shtaketin is the easiest option.

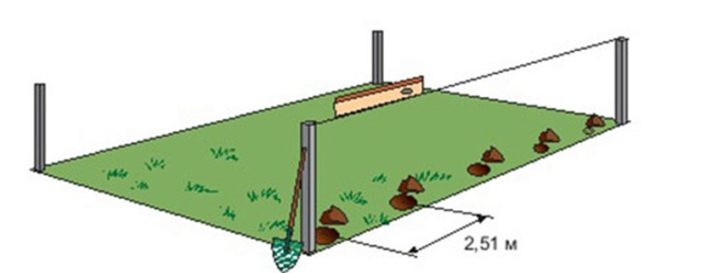

The length of the spans between the support columns is taken equal to 2.5 m. For supports, a third of which sinks into the ground, bars of 3 m are taken. The quantity of sawn timber is calculated according to the following algorithm.

The number of pole supports is equal to the total length of the fence, which must be divided by the distance between the columns. This also adds poles for wickets and gates.

The total length of the horizontal jumpers is equal to twice the length of the fence. Here you need to add 10-15% overlap, trim and waste. The amount of slab will depend on the size of these boards. It is calculated by dividing the available result by their length with the addition of a small margin.

The number of shtaketin for a continuous fence can be calculated by dividing its length by the average digit of the slab.

It is better to purchase timber with a small margin, since in the process of barking, grinding and subsequent processing, part of the slab will be rejected.

Fence construction

This process begins with the cleaning of the bark of slab and its antiseptic treatment.Then follows the laying of the route for such a fence, marking the places for mounting the pillars, as well as their installation in the ground. The final stage is the mounting of transverse rails and picket boards.

In winter, the construction of the fence is better not to do, as there will be difficulties with drilling holes, and all the work because of the cold will take much longer.

Each of these stages will require a lot of time, so you need to count on the implementation of all the work for a few days in advance. The process can be accelerated by attracting several assistants who will begin to perform separate operations in parallel.

Crook humping

The practice, which has more than one century, shows that the most rational way to remove bark from the surface of wood is the removal of it with scrape. This tool is a steel strip with two handles sharpened on one side. For them, the scraper is pulled along the trunk, scraping the bark off. This method allows you to save the intact surface of the wood is not an example of an ax, a pointed shovel and power tools, which significantly extends its life.

For logs okorenie okorechenie through sharpened shovel, which makes it possible to quickly remove them from the bark. For lighter crooks, this method is not suitable, because they are pulled after the tool.

The slab for this operation is placed vertically with support on any reliable object, for example, on a wall or fence. Chasing is done by moving the scraper from top to bottom. If necessary, knots are cleaned, and the plank is aligned at the edges with an ax and planer. After the bark has been completely removed from all wood surfaces, an antiseptic is applied to them with a brush., and the whole processed croaker is left to dry.

This preparatory stage is the most time consuming in the construction of the fence. The longer such a fence will be, the more material will have to be recycled.

Plot marking

While the croaker, peeled and treated with an antiseptic, dries, it is necessary to start marking the site. It is necessary to begin with finding the corner points of this section, marking them by driving there stakes, between which the cord is then tensioned.

The places where the supports will be installed are planned to be passed with a tape measure on the cord. The standard value here is every 2.5 m.. You can do a little differently, alternating along the entire length of the intervals of 2 m length with sections of 2.5 m, if there is a risk of getting one short span at the end.

Next, you should drill holes in the planned points to a depth of 1 m, without removing the cord.

If the planned height of the fence should be 2.5 - 3 m, then it is necessary to take into account the increase in its windage and wind load on the fence. To do this, the distance between the pillars of the pillars should be reduced to 2 m, and the pillar in the ground should be set to a depth of 1.2-1.4 m.

Installation of pole supports

Intake pillars can be installed by hammering them into wells, assembling with the use of blocking, concreting. If the installation of pole supports in wells made by a gasoline drill is used, their diameter should be somewhat smaller than the cross section of the beam itself.

The first two methods are often used to install wooden poles. Before installation, the lower parts of such supports are covered with resin or bitumen masticand then driven into the wells. After that, it is necessary to pour soil around the post and tamp it down.

In the second case, a pole support is put in the dug pit, filled with stones from all sides and filled with liquid clay.

Concreting can be fixed as steel supports, and wooden. but anchoring parts are pre-welded to steel poles for firm fixing of the pipe in the thick of concrete. They can be pieces of reinforcement or a corner.

The combined variant is also used when a steel tubular support is concreted into which the wooden support is installed.

In any case, the work is carried out in a way when the bottom of the pit is filled up with 5 cm of rubble and it is compacted. The rack is installed on a level strictly vertically and fixed with support rails. Concrete is mixed from 1 part of cement, 4 parts of sand, 6 volumes of gravel and water. With this mixture, the pit with the racks is filled to the top. Subsequent work is done after the concrete has set.

Steel support pillars can be installed according to the method called a concrete collar. Having a hole with a depth of 0.5 m, the pipe is driven into it another 0.5 m below its bottom and filled with concrete.

In many Russian regions, there are often ultra-moist soils that swell from frost. In winter, they are able to push out to the surface any object that is in the zone of soil freezing.

In this situation, the concrete is poured below this level, and on top of the support, the wet soil is replaced with a mixture of rubble and sand.

The construction of the fence

At the final stage, transverse lags are installed, to which the shtetins are attached.

The cross-beams are nailed to the posts. If wooden bars are used as logs, their position should be calibrated by level. The croaker itself is better aligned, so to speak, "by eye". For this, an assistant, standing several meters away, must correct the position of each of the crossbars.

Neighboring cross-beams can be nailed butthed, as well as by placing them one on top of another vertically. Lags, consisting of slabs permissible to mount overlap.

The first shtaetina is nailed after leveling the vertical. In each place of attachment of shtaketin to the logs, two nails should be hammered. The remaining shtaketina attached, clinging to each other, with periodic verification of their vertical position.

If metal racks are used, logs are bolted, for which through holes are drilled in the pipe. In another embodiment, self-tapping screws are used, which significantly increases the cost of the process.

To protect the upper ends of the fence strips from precipitations on top of them it is best to fill the visor, made of the same croaker.This is the last operation in the construction of such a fence.

Thus, to build a beautiful wooden fence from slab is not an extra hard job, although it requires considerable labor costs. However, such a serious complexity is successfully offset by low costs. For optimal use of personal time, the whole process is better divided into stages, performing as much as possible each of them. This especially applies to owners of sites with a large area, if necessary, their fencing from all sides.

In this situation, it is advisable to install the fence in parts, starting from the front of the site.

Review the finished fence in the next video.