Caps for fence posts: features of choice

A beautiful and reliable fence for centuries, so as not to squint and not fall apart, so that the neighbors envy and not to repair at all. This is the result that every homeowner wants to get when he starts designing a new fence. Today, such results are quite achievable with strict adherence to technology and proper selection of materials.

A reliable foundation, powerful pillars, beautiful durable panels - these are the main elements of the modern fencing. There are also elements of protection that just do not allow supporting posts to collapse.

What it is?

These are caps that are mounted on top of the pillars. They look like pyramids or small roofs, they can be round, and a variety of other forms. In any case, the shape of the lid causes water or snow to flow down, various grooves are possible. Sometimes the cap has a sharp tip or decorative elements, figures, lamps.It is carried out from various materials which have one main property - resistance to the effects of aggressive environmental influences, precipitation.

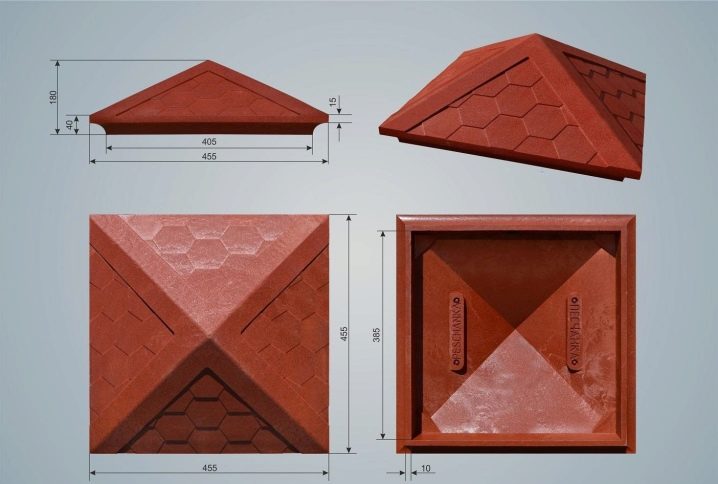

The design of the covers consists of the following elements:

- The upper part is an overlay on a pole, the edge of which protrudes beyond the edges of the column, covering it from above, usually has slopes, grooves, planes for water flow. The overlay is made hermetically, inside it is usually hollow.

- The lower part, the so-called skirt - mount. Typically, the mount is made so that after installation it was invisible.

- Additional components, such as decorative items or built-in lights.

Functions

The main problem arising in the process of building and operating brick or concrete supports for the fence is water and moisture from entering the surface and inside the column, especially if it is hollow.

Brick and concrete are very durable materials, the structures of them stand for decades, but moisture destroys the structure of bricks and concrete, it begins to crumble.

Washed and blown mortar solution. Darkening and deformation begins in the upper part, where water flows.In the hollow pillars stuffed dirt and debris. With subsequent freezing, the water expands and destroys the pillar even more.

Under such impacts, the service life of the bearing pillars of the fence will be short, and repairs constant and frequent. Overhaul of the fence will cost much more and take considerable time.

Pads solve these problems and perform the following functions:

- Caps protect the brickwork from water, sun and wind, as well as from mechanical influences, preventing the destruction. Metal pipes, reinforcing pillars from the inside, also need protection from corrosion. Plugs in the form of slats and close the fence panel.

- The decorative function is also important. These figured caps, fancy shapes, textures and colors create a finished look of the fence and give it a unique style.

- Covers allow you to embed additional lighting.

- Pointed peaks at the tops of the pillars will become an obstacle to penetration into the territory of homeowners intruders.

Primary requirements

Caps can be made independently, and you can choose from a huge range of materials, colors and shapes, which today offers the construction market. In any case, these products must have the necessary technical characteristics:

- Strength. Such covers are designed to serve for more than a decade.

- Tightness and integrity of the upper part to perform the main waterproofing function.

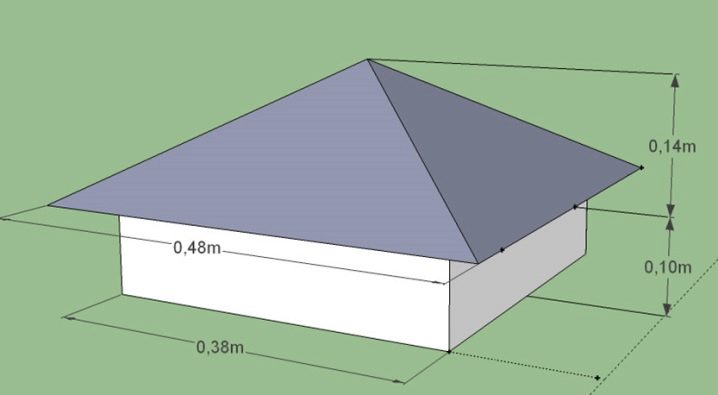

- Requires a slope for the flow of water, overhangs should protrude beyond the edge of the column.

- The possibility of ventilation for hollow pillars with special holes.

- Strong and inconspicuous fastenings.

- Place the drop from the edge of the overhang should be tightly closed.

- Resistance to external loads and impacts. The material must be protected against corrosion.

- Compatible with other elements of the fence and additional details.

Kinds

For the production of plugs for the bearing supports of the fence used a variety of materials. The main types of elements:

- Concrete (clinker). Poured in different shapes, affordable, easy to attach to the solution. Have a significant weight (up to 20 kg), which complicates transportation. They are not suitable for mounting on wrought, wooden and metal fences, but they are perfectly combined with concrete, brick and stone.

Such plugs can be made by hand with the help of a metal mold and a concrete solution.

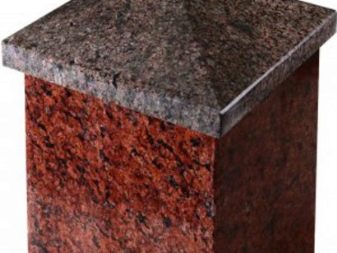

- Stone, cut from natural marble or granite, they are distinguished by high strength, considerable weight, they have the longest service life, they can stand for centuries.

- Ceramic, mosaic, rather fragile, quite expensive, but very elegant.

- Polymer-sandy, are the latest development of manufacturers; durable, have an attractive appearance, affordable and gaining increasing popularity among buyers.

- Metallic, made of copper or tin, galvanized steel, stainless steel. Can be decorated with wrought iron elements. Subject to corrosion, so be sure to top covered with polymer compositions of polyester, plastisol. Perfectly combined with corrugated board, often used with it.

Copper lids can last up to 120 years, brass up to 60 years. Low weight allows you to transport products in the trunk of a car.

- Plastic made of PVC, very light, inexpensive.

- Wood. The most short-lived, rather, are used as a decor, fit perfectly into the general appearance of the site, are easily made by hand, treated with impregnation against rotting and covered with paints and varnishes.

- Bituminous, from liquid rubber, soft tile. Often, after roofing, a lot of scraps of soft tiles or other materials suitable for the manufacture of high-quality materials remain. After arranging the floor screed remains liquid rubber, which is used as a waterproofing agent.

- Fiberglass. The dielectric properties of this material allow them to install fluorescent lamps.

Different covers and manufacturing technology. They are cast, welded, stamped, forged, bent. There are also differences in design, shape and decor.

Models with built-in lights are very popular, they allow to solve the problem of lighting the perimeter of the site and create a beautiful external impression.

Welded and forged caps look impressive and stylish. Mosaic ceramic caps look wonderful, elegant and modern.

Forms of covers - a huge set. Classical pyramid with four slopes, the cover can be a gable, stepped. Popular option in the form of a miniature Chinese roof, produced caps with imitation tiles, wood, stone, other materials. The surface can be smooth and matte.

You can decorate caps by attaching decorative elements to the top. These can be rings, spheres, pointed peaks, figurines and mini-sculptures, lanterns and lamps.

How to choose?

In order not to be mistaken with the choice of protective caps, it is necessary to take into account the materials from which the fence and supporting supports are made, to make sure that they are compatible. For example, concrete covers due to their large weight, mounting features and appearance are not mounted on forged, metal and wooden poles. Also, it is impossible to attach metal spikes and forged elements to them.

Metal finishes are often used for mounting on poles of additional street lighting, due to its hollow form. They will fit all types of bearing supports. Especially harmoniously combined with brick pillars and spans of metal profiles.

For marble columns and balusters choose the same marble tops. Then you need to make all the measurements, determine the overall style of the fence, color range. The choice of form depends on the taste and desire of the owners. Well, if you get a single harmonious ensemble.

When buying ready-made tops, it is important to pay attention to the following criteria:

- Factory covers must have all accompanying documents: checks, certificates of conformity.

- All copies must be the same, they are checked for symmetry, compliance with the declared dimensions, angles and dimensions of fasteners are measured.

- You must ensure that there are no visual defects in the form, coating, cracks, chips.

- The packaging must be intact and of high quality, otherwise during transportation, damage to the caps may occur.

- Be sure to check the completeness of the set.

If among the finished goods there is no suitable size or desired shape, then almost all manufacturers make caps for individual orders, according to the drawings provided or measurements made. To take measurements from the office, a measurer will arrive, he will do all the calculations and carry out the drawing of the product. The client will only approve the selected option. The execution of work takes 10-14 days.

Factory tops and made by the manufacturer to order receive excellent reviews from the owners of households, where the pillars and fences protected by caps stand for many years without the need for major repairs. Buyers note that all costs for the purchase and installation of plugs pay off in the process of operation.

It is easier, faster and cheaper to install protection than to do a complete overhaul of the fence: disassemble the destroyed tops of the pillars, re-lay, plaster the cracks.

You can make a plug with your own hands if you have the necessary skills to work with concrete and metal, wood, as well as equipment and tools. For casting concrete caps, you need to make a metal mold according to the master's plan, prepare a cement-sand mortar with plasticizers and, if desired, add fine reinforcing fiber for greater strength.

As the plasticizer is perfect for the cheapest liquid soap or dish detergent. In the tank, mix the dry ingredients first and then add water. Then pour the mixture into the mold, cover with film, wait until it is completely dry.

Wooden caps are cut from blanks with a saw, a jigsaw, then polished, impregnated with an antiseptic, covered with outdoor varnish or paint for the street.

Metal tops can be made of galvanized using a sheet bending machine or a corner so that the fold lines are smooth.Fasten the bent pattern with rivets, attach a metal strip for the skirt from the bottom, paint it in the desired color suitable for the other shades of the fence, dry it.

Installation

During the construction process, the posts are protected with a thick plastic film, wrapping the upper part and fixing the film with a rope. When brick supports are laid out, you can install protective tops. This is a simple process, all the work can be done by hand. If the caps are planned to be equipped with lamps, then it is necessary to bring the insulated wiring to each pole. For clinker plugs, cement-sand mortar will need to be mixed, and for ceramic ones - tile adhesive for street work.

Protective slats and skates are mounted on the entire surface of a brick or concrete fence, protected by columns, balusters of stair railings on the street, for example, on the porch, terrace. Close chimney pipes from rain, snow and debris.

The sequence of installation of concrete and ceramic caps:

- Remove plastic wrap, clean the surface from dirt, dust, dry.

- Walk along the top of the pillar with a primer for better adhesion.It is desirable to process the entire upper part of the column with a waterproofing impregnation.

- Apply mortar or tile adhesive to the joint.

- Place the lid horizontally, if necessary, place wooden pegs under the cap, check the position with a level.

- Wipe the seam between the post and the cap, soak a waterproofing agent.

The solution hardens completely within 2-3 days, during drying it is not necessary to touch the seams. Then it is possible to install decorative elements, which are also planted on tile adhesive or on mortar.

Metal caps are lighter, thanks to a special hollow form, they are mounted as follows:

- Mark the exact mounts.

- Drill holes in the pole at the points obtained.

- Apply a special glue or screw the bottom with a screwdriver and screws or dowels.

- Put the upper part on the skirt with a separate design.

Installation of protective caps is the final stage in the construction of the fence and gate, but in order to serve the fence for a long time, you must not forget to monitor its condition. Behind caps need regular maintenance and inspection for damage.It is necessary to wipe chutes and glass lanterns with a damp cloth, tint metal and wooden parts as needed.

How to make a cap on the fence post with your own hands, see the next video.