Slate fence: design features

Almost every owner of a private house or suburban area, acquiring a building or being engaged in the construction of a new one, takes care of the safety of the territory of his possession from outside penetrations and other people's views. To do this, around the perimeter of his plot, he installs a fence.

Special features

Today, manufacturers offer a wide range of building materials to create a fence. Fences can be made of wood, brick, natural stone, glitter mesh or chain-link, sheeting, concrete slabs. There are status options for iron fences from forged, welded metal and their combinations.

Any type of such fencing has several advantages. Most of them are beautiful and good-quality, differ in reliability and durability, as well as a variety of design, but at the same time they have a certain number of disadvantages. Here there is a solid cost, and the complexity of their installation, and the need to involve professional specialists and construction equipment in their construction.Often, all these factors are prevalent when choosing fencing.

Nevertheless, there is another affordable material that does not create technological difficulties in constructing a territory fencing from it - slate. A fence from it equally soundly and thoroughly can be erected both in the village or suburban area, and in the city. True, slate is quite fragile and afraid of shock loads. It is better to erect fences out of it from the roadway, for fear of accidental stones from under the wheels or some surprise from street vandals. It is more expedient to erect a fence from this material somewhere inside the plot, for example, by enclosing a yard from a garden or garden with a slate fence, or to install such a fence on the border with the possessions of neighbors.

Slate is a long-known building material. It is made by mixing asbestos with cement and water.

Asbestos fibers, evenly distributed in this mass, create a strong mesh, ensuring the stability of the material in tension and giving it the appropriate toughness.

Species

Most people distinguish between two types of gray slate: wave and flat, without knowing some of the nuances, information about which may be useful in choosing the right material. So, flat slate exists in two forms: pressed and non-pressed.

The first option is much more massive, so its strength indicators are very high. Due to the high density of its sheets, their strength increases to 25%, and the impact strength of such slate reaches 2.5 kJ / m2. Due to this circumstance, the fragility of this material is not so high. This also implies its other property - frost resistance, which is why an extruded type of slate should be considered the most favorable option for creating a sufficiently strong fence.

Wave-type slate also exists in several varieties., of which the most interesting are its painted sheets from modern manufacturers, who have managed to significantly expand the range of this building material. Therefore, now it has acquired a more attractive appearance, saving the consumer from the need to paint the fence. Sheets of such slate due to the specific shape of the profile of asbestos cement are more rigid and durable, having even a small thickness of about 4.7-7.5 mm.

If the wave slate is chosen for the construction of the fence, then the “UV” mark will be the best option - a unified profile type. His sheets are distinguished by a density that is more significant against the background of wave analogues, and their sizes allow working with them with sufficient ease and convenience.

The weight of one sheet of this brand does not exceed 26 kg, and its width allows to minimize the consumption of material.

Properties

Slate is a material made from a mixture of asbestos with Portland cement and with modifying additives. All of these ingredients are stirred in the manufacturing process in water until a thick, homogeneous mixture is obtained. It is pressed on the appropriate technological equipment and further high-temperature drying.

The advantages of this material are in its affordability. Thus, the cost of a sheet of wave slate 1750 × 970 mm with a thickness of 5.2 mm is about 205 rubles.

Asbestos cement slate is a fairly durable material. His sheet is able to withstand a point load of about 70 kg or more. At the same time such material is not subjected to deformation and is not covered with cracks, while continuing to maintain the factory form.

Another useful property of slate, produced along with other building materials in accordance with GOST, is its durability. For unpainted material, the minimum lifetime is about 30 years.

Sheets of the painted product will serve over 50 years.

In addition, it is very resistant to frost. Asbestos cement is among the porous materials. This allows slate to retain its properties for a long time under the influence of low temperatures for a very long time. Slate is also a very reliable material, since it is not susceptible to corrosion, cannot serve as a breeding ground for insects and mold fungi, it is not affected by moisture and heated to high temperatures.

Due to the presence of a protective coloring layer, colored grades of wavy slate are not so sensitive to the effects of water on them and withstand negative temperatures better. The painted sheet is 1.5 times longer than its usual equivalent of the same thickness.

All these qualities are manifested by slate in those situations when it is used directly as a roofing material.When it is used to build fences, it can manifest itself in a slightly different way. In such a fence sheet of slate is placed vertically, so there is a risk of impact on his sheet perpendicular or tangential, which is fraught with cracks or spalling.

The weight of the smallest sheet of slate wave type is 18.5 kg, and for its flat counterpart, this indicator ranges from 75-350 kg. The use of such heavy sheets will require more reliable concreting of the base for the bearing supports and the use of appropriate fasteners.

Asbestos, which is present in the composition of this material, when it is drilled and cut forms dust harmful to humans.

Therefore, it is necessary to work with him in the means of protection of the respiratory organs and vision.

The construction of the fence

The length of the fence is measured by a tape measure around the perimeter of the territory of the site.

Its construction is carried out in several ways. The most reliable and stable type of such a structure is a fence mounted on a tape type foundation. To obtain such a foundation, it will be necessary to pour concrete into the pre-installed formwork. If the territory of the site has irregularities with differences in height, then for even placement of the formwork you will need to prepare the foundation.

A simpler technology is to install a fence on concrete supports. This method is used for stony soils and sandy soil types.

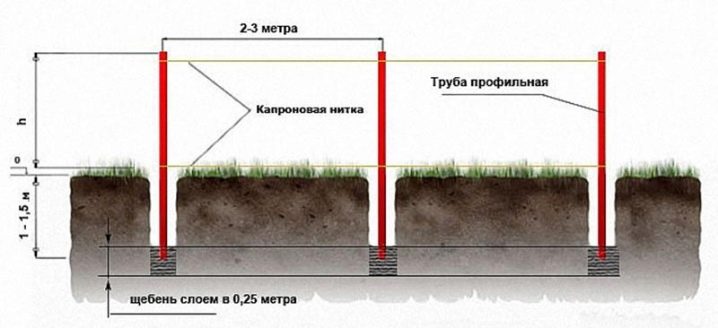

If a fence is erected according to this method without filling the strip footing, then the perimeter of the fence is marked, and the installation positions of the corner supports are indicated. For this purpose, the measurement of the estimated parameters of such a fence is performed. At the nodal points are hammered pieces of reinforcement or wooden stakes, between which the fishing line is stretched.

At these points, a manual or gasoline drill is dredging at a depth of about 70–90 cm. Drilling on stony soils requires special attention, as the cutting edge of the tool is damaged and blunt at high speeds. The traditional alternative to such borax will always be scrap, shovel and pickaxe.

Pillar supports are treated with bitumen varnish twice to protect the metal from corrosion. After drying, the concrete is kneaded.

Before installing each of the supports on the bottom of the pit stacked double folded piece of felt. Then the support is installed vertically in the pit, leveled by level and is poured with concrete with its periodic tamping.

If necessary, you can pre-zabutovat column with stones or small gravel.

Concrete is mixed from 1 part of cement, 4 parts of sand, 6 volumes of gravel and water. With this mixture, the pit with the racks is filled to the top. Subsequent work is done after the concrete has set.

Steel support pillars can be installed according to the method called "concrete collar". Having a pit 0.5 m deep, the pipe is driven into it another 0.5 m below the bottom and filled with concrete.

Similarly, the work is carried out on excavation of pits and installation of supports in them at the other reference points of the entire perimeter of the territory. When this work is finished, intermediate pole supports are laid out and set in 2.5 m steps and corrected for gates and wickets.

After the concreting of all the pillar supports is completed, it is necessary to wait for the final hardening of the concrete mix, which lasts about 7 days, so that the concrete gains the strength necessary to withstand the weight of the sheet slate.

While the concrete is hardening, it is necessary to start cutting steel strips from a corner, which is cut into pieces with a length of 200–250 mm.At the edges of these elements, holes are drilled to attach guides to them. Then these fragments of the corner are welded to the column in the upper and lower parts, with indents from the top and bottom of 200–300 mm.

The guides for fixing sheets of slate will be wooden bars with a cross section of 50 × 130 mm, which are fitted along the length of the span. The timber before installation on the supports should be treated with wood antiseptic.

Then at the fixing point of the guide beam to the corners, welded to the post supports in advance, the through holes for the clamping bolts with which the guide rails are attached to the support are drilled.

After that, a sheet of slate is placed on the guide rail and is set at the level. At the same time, it is necessary to observe the distance from the ground equal to 10 cm in the lower part of the fence. The slate sheet is fastened with galvanized self-tapping screws and a rubber washer per fastening step of no more than 30 cm, for which a mounting hole is drilled in the sheet.

Sheet slate is attached through the peak of the wave, and to join the sheets, the upper part of the wave of one sheet is superimposed on the peak of the wave of the previous sheet. If it becomes necessary to cut off some part of the slate sheet with a “grinder,” it should be moistened with water to prevent the formation of asbestos dust.

Fence decoration

Color slate of one of the modern brands is a universal way to solve the problem of finishing the fence after its construction. Such a fence will have a form not inferior to counterparts from metal. Its color is better to choose, given the main color of the surrounding buildings.

If the fence was built from ordinary unpainted gray slate, then its design can be successfully carried out using an acrylic dye of the desired color.

For application to a previously cleaned surface, the latter is treated with a metal brush and covered with an antiseptic.

Paint is applied by spray gun or paint brush, which slightly increases the consumption of the dye. After painting, the slate fence not only acquires a more aesthetic appearance, but also receives additional protection in the form of a thin water-repellent layer.

There are special dyes for asbestos-cement surfaces, giving them a more reliable protection. Such paints for slate are somewhat more expensive than acrylic compounds, but their service life is much longer.

How to make a fence from the slate with your own hands, see below.