Brick and corrugated fences: installation features

A fence made of brick and corrugated flooring will be a good solution in the design of a country house and a highlight in landscape design.

Features and benefits

The fence is necessary in order to enclose its own territory, to hide the site from prying eyes from the street, to avoid the entry of unwanted guests in the form of domestic and wild animals, as well as criminal elements.

In this case, the fence gives integrity to the design of the entire site. For example, if a house is brick or lined with brick, and the roof is covered with metal tile, a fence made of brick pillars and ceilings in the tone of the roof will be another stylish element in the ensemble of the site.

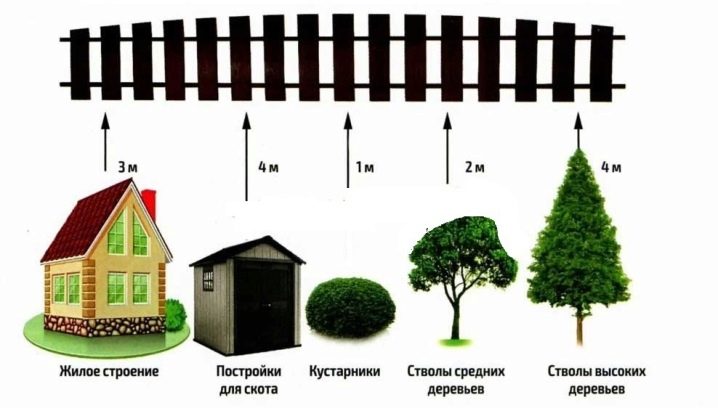

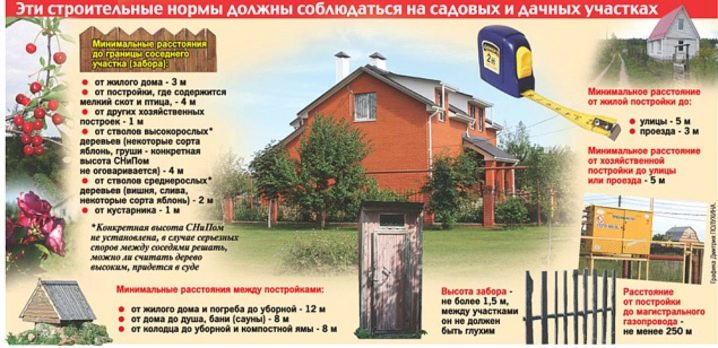

Standards and regulations

For the construction of the fence must adhere to building codes and regulations (SNiP).Failure to comply with them can lead to administrative liability in the form of a fine. There are also rules related to the observance of fire and sanitary standards. These standards determine the distances that must be maintained during the construction of the fence. Distances are associated with underground gas, water supply and above-ground structures.

An important role is also played by the height of the fence. The device of deaf barriers is prohibited on the border of the neighboring areas. This is due to the fact that the deaf fence will shade the neighboring territory. In order to resolve this issue, it is necessary that the neighbors must consent not only verbally but also in writing with the involvement of witnesses. The height of the building, as well as other dimensions, can be found in the municipal regulations by calling or visiting the local administration.

Land squatting is prohibited by law. The fence can be built only on the land, which is owned.

It is necessary to have a certificate of ownership and a site plan. If you want to increase the land plot need to buy and get the relevant documents.

Species

It should be noted that a brick fence will look like a medieval building - powerful and bulky. In addition, this would entail unnecessary financial expenses.

A half brick width is completely unreliable and will quickly collapse. For good adhesion of masonry, it is necessary to lay at least a brick, while constantly reinforcing it with iron rods or a grid vertically and horizontally. If you count the number of bricks to get around at least 6 acres, then it will be enough to build a house.

Building a fence using profiled sheeting is a more economical, but no less stringent and stylish option for erecting a fence. The profiled sheet has a large sail area. To achieve reliability, this material requires a reliable skeleton on which it will be mounted. Brick pillars will serve as a good mount and reinforcement for the skeleton, as well as give the object solidity and power. The design possibilities are endless.

Calculations

Before the start of the installation work, a fence design is made, a plan is drawn up and the amount of material (brick, decking) required for construction is calculated.

After selecting the material is a drawing. It takes into account what tools are available for construction work and what materials are available for this or need to be purchased. The installation process will depend on their availability. That is, the quality of installation will be the same; it will simply be performed in various ways and using different materials.

These tools include:

- concrete mixer;

- welding machine;

- electric generator (in the absence of electricity).

If some tools are not available, then some metal parts can be replaced with wooden ones.

When calculating installation work, it is necessary to take into account not only the material possibilities, but also the availability of electrical supply and natural resources at the site or in the vicinity. Such resources include water, sand, clay, rubble. The condition of the soil where the fence will be installed is also taken into account. If the site is new, then pre-landscape and communication works are carried out on their own or with the assistance of heavy machinery. It is more convenient and saves energy and costs in the future.

When the site is already built up and has significant differences in relief,then it is broken into several parts. Parts will have a span, which in most cases is 3 meters. The length of the span can be increased to a maximum of 6 meters due to the high sail sheeting. At the request of the owner and if the terrain allows, the fence can be made entirely of profiled sheet, and the pillars can be installed in the corners of the site and the places where the gate and gate will be installed.

Foundation

For high-quality installation you need to make a foundation for the fence. This design looks more beautiful, it is more reliable than the deaf overlap profiled. The professional sheet can be mounted already after laying of the base.

The foundation will not let through weeds, for example, wheat grass, on a personal lawn. Undermining it will be more difficult for wild and neighboring animals. He will save from spring or spontaneous flooding.

The completion of the design are the covers on the pillars. They are concrete, covered with mineral pigment and metal. They are made of different types and colors. They can be made independently. They protect the brick pillar from moisture, prolonging its service life, and give the completion and originality of the design.

How to choose?

There are many types of bricks, and any of them can be used in the construction of the fence. Most often use the remaining brick from the construction of the house. Fight and waste will be used during the installation of the foundation, which will save on garbage collection.

White silicate brick will be perfectly combined with any dark color of the professional sheet. Ordinary red brick is cheaper and more accessible. You can try to combine different colors of bricks. For example, in staggered order or in the form of a spiral.

The pillars and the foundation of the fence can be trimmed with mosaic or natural stone.

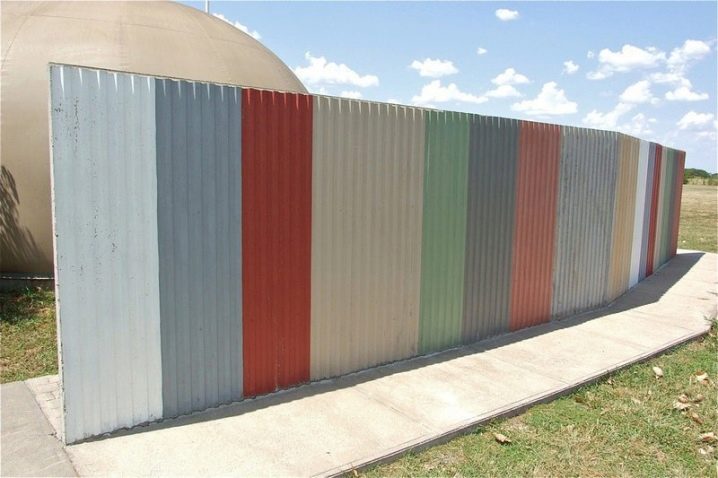

The color gamut of profiled sheets, commercially available, is very diverse and allows you to satisfy every taste. But if you wish, you can paint them yourself in a suitable shade using a spray gun. Modern selection of paint products allows it to be realized.

Sheet configuration is mainly wave with different pitch and depth. They can be mounted both vertically and horizontally. The thickness of the metal for the construction of the fence is chosen not less than 0.5 mm. Under the order it is possible to purchase sheets of wood or brick.

How to install?

To install the fence, you must perform the following work in a certain sequence:

- foundation preparation;

- making skeleton;

- foundation casting;

- bricklaying;

- installation of a professional leaf;

- fine finish.

Installation work begins with markings on the ground according to a previously drawn up plan. The markup is made with the help of a pedometer or a tape measure, driving pegs into the places where the pillars are installed and at the borders of the future fence. Between them they stretch the nylon thread. They dig a trench along the thread with a depth of at least 25-30 cm. In places where the pillars are located, the depth must be increased to at least half a meter. Width is chosen arbitrarily. If there is a subsequent laying of bricks along the entire perimeter, then it should be equal to the width of the laying. If the soil is soft, then to strengthen the foundation, a trench is dug with expansion in depth. The largest depth for the foundation is the depth of soil freezing, about a meter. The soil is distributed over the site or exported.

The next step is the installation of formwork. One of the mounting options will be pouring concrete not only into the foundation, but also the pillars themselves, followed by finishing them as bricks.Such a monolithic design is the most durable.

For the construction of formwork, you can use any available material, but most often use a half-edged board. They assemble boards according to the level of arbitrary height, leaving a distance of at least 10 cm from the ground. The boards are fastened together with transverse bars and propped up on the outside. After that, an iron skeleton is assembled from rods with a cross section of 8-10 mm. It can be assembled directly inside the formwork or made from the outside and placed inside the already assembled one. Used for the assembly of welding or burned wire is used. The length between the vertical bars is usually 1-1.5 m.

Next, install an inch pipe or an iron corner of at least 30/30 in the center of the future post, which will strengthen the pole and will serve as the basis for fixing the guide rails for corrugated flooring. Level it and fix with struts. You can weld it to the skeleton of the foundation.

Start to fill the foundation. If there is no electricity or a concrete mixer, use a home-made or metal trough with a size of at least 1 / 0.5 / 0.4 m.

The proportions of the concrete mix: 1 part of cement, 3 parts of sand, 6 parts of crushed stone; water; 10 ml per bucket of water of liquid soap. First, make a cement mortar, and then add crushed stone to it. Used when kneading shovels and hoes. When the amount of work is large and there is a possibility and labor, it is possible to calculate the volume of the solution and order a concrete truck. Concrete is poured in to fill in air bubbles. After pouring, cover it with polyethylene for even setting. The formwork can be removed after a week.

2-3 days after the foundation has been poured, a framework of 1.5–2 mm thick iron hollow bars or corners is welded, the dimensions and thickness of which depend on the length of the span. Layout and assembly are done by two people using a water, laser or simple level. After installation, the welding places are painted. If wooden bars will be used as guides, then during the laying of the pillars in the brick, mortgages are made for their fasteners.

The brick is placed on the cement mortar with the addition of a small amount of liquid soap to increase the elasticity of the solution. In order to save money, they put one brick in half, reinforcing it with an iron net and at the same time pouring cement into the center of the pole with an iron guide. The height of the pillar is individual. Usually it is adjusted slightly higher than a sheet of corrugated sheet.

The profiled sheet is attached to the guides using self-tapping screws with rubber gasket or rivets. It overlaps and is mounted through the wave. Use a screwdriver, drill or hammer drill with a nozzle adapter.

On the foundation with brickwork or without it put the ebb. It can be made of the same material as the fence, or made individually. To protect against water and impart completeness to the structure, on top of the pillars a brick visor is placed on the solution or an iron one is mounted.

Finish the manufacture of the fence mounting wickets and gates, which can be varied: sliding, hinged, mechanical or universal.

How to make a brick fence with your own hands, see the next video.

Design examples

The ability to realize your imagination when building a combined fence is limitless. For example, it is possible to cast pillars with mortgages for fasteners of plaster profist in the form of statues and install them into the foundation. From the same gypsum make various inserts that are mounted in the brickwork.

The profiled sheet, decorated with its own pattern, will give the fence an original look.Translucent polycarbonate sheet in combination with opaque elements will be an elegant decoration of the fence of your site.

Decorations in the form of turrets on brick pillars will make your country house a truly fabulous place.