Foam for wall insulation: the choice of material for thermal insulation

Devices and devices for heating buildings will not be able to effectively cope with their functional tasks without properly and qualitatively warmed foundations of the structure: roofs, walls, foundation and floor. For these purposes, various materials are used, differing in their technical characteristics and properties. As for the wall insulation, in this case it is worth highlighting such a heater as foam, which has found its application in modern construction.

Special features

The specificity of the climate makes it necessary to resort to the use of different ways to maintain a comfortable temperature in a residential house. It is foam that is presented on the market in various ways that not only allows sealing the gaps, but also acts as a heat-insulating material.

Residential buildings require compulsory warming, since the internal microclimate will depend on the performance of these works both in the warm season and in winter. As a result, living in such a house will be comfortable for residents, regardless of the outside temperature.

In addition, products for insulation positively affects the durability of the structure, providing a certain level of protection to materials from the effects of external factors.

It should be noted that the use of foam is a rather topical issue from the point of view of energy saving.Because the rise in tariffs for services makes it necessary to look for alternative ways to save heat in the house as much as possible.

Today, on the shelves of supermarkets and markets, a large assortment of insulation is presented, but it is precisely the foam-forming goods in cylinders or large containers that have become in great demand.

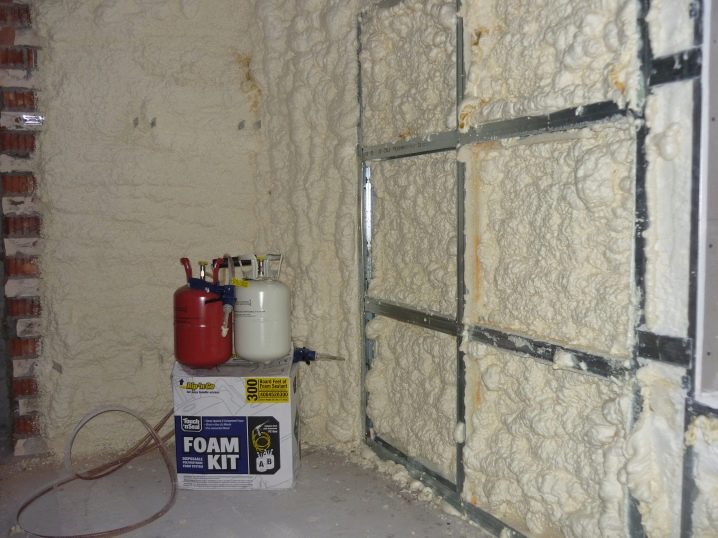

Polyurethane foam can be used both for interior work with bases, and for processing the facade from the outside. Products represent a rather effective variant of thermal insulation, since it is the gaseous components that are characterized by the lowest values of thermal conductivity. Foam, in the case of its enlarged view, has a porous structure, due to which a layer of immobilized air is formed.

It is presented in several varieties. The main differences of commercially available materials are that one substance is realized in a liquid state, and the other type is a semi-liquid two-component composition.

Sprayed products are applied to the working surface, where the process of foaming occurs during the chemical reaction of the constituent components of foam and air. The resulting substance increases in size to the required volume, after which the process of solidification of the insulating composition takes place.

It is worth noting the positive features of the use of such insulating materials.

- High level of adhesion of foam with various bases. Therefore, to perform the work there is no need for arranging additional frames, as is the case with products in the form of blocks or mats. This feature allows you to save money, as well as significantly reduce the time to conduct thermal insulation of the building.

- Due to its structure, a substance such as foam will exactly repeat the shape of the surface of any complexity, which facilitates the creation of the thermal insulation layer, and also makes it possible to attribute these products to universal goods.

- The ability of the material to expand from contact with air allows the foam to easily penetrate into any slot, even with minimal dimensions, which is important for the insulation of windows, pipes, ceilings, etc.

- At the end of the polymerization process, the foam forms a monolithic layer without seams, which is the main feature of the product, since not a single rigid type of thermal insulation material has a similar quality.

- Considering such an indicator as thermal resistance, foam for insulation is characterized by a maximum value, so the level of insulation, even with a small layer of substance, will have the highest characteristics.

- For the sprayed composition is not necessary to carry out complex work of a preparatory nature with a working basis. The whole process of treatment consists in applying and waiting for the foam to harden.

- Due to the porous structure, the material additionally provides sound insulation of the premises.

- The substance has a minimum weight, therefore it does not burden the base.

- After the final solidification, the foam becomes completely safe for human health and the environment.

- The composition does not form microorganisms.In addition, the foam will not act as a habitat for insects and rodents.

- Almost all types of foam for thermal insulation are well tolerated in contact with the metal, providing protection against corrosion, preventing the penetration of water and steam. As a result, the composition acts as a waterproofing layer, which is important not only for the walls, but also, for example, for the roof and various floors.

- Production possesses heat stability: material maintains heating to +80 C.

In addition to the above advantages, foam is characterized by the presence of some disadvantages.

- For the insulation of walls and other surfaces requires the use of special equipment, which in some cases complicates the process of working with their own hands.

- Such a heat-insulating product has a rather high cost in comparison with other types of building materials that allow to insulate buildings.

- Most of the foam compounds are not resistant to ultraviolet, so it is necessary to ensure the deposited heat-insulating layer reliable protection from the sun's rays.

- Some foam components are toxic,therefore, when applying the composition, it is necessary to strictly observe individual safety measures. However, after complete solidification, it does not pose a threat to health.

Types and characteristics

Foam for insulation classify based on the composition and structure of the material, so you can select several types of products.

- Penoizol. The composition of the heater includes components of the aldehyde group, due to which it is dangerous to humans. The polymerization period is 72 hours. Foam is recommended for use on walls, bearing elements of various designs, for processing attic spaces. On sale you can find products in the form of plates or in the liquid state.

- Foam concrete. This composition is sold in cylinders, but some experts do not recommend its use for work with the facade. This is due to the large mass of substance, thereby increasing the load on the surface.

In addition, foam concrete belongs to a line of expensive goods.

- Polyurethane foam. Based on the technical characteristics, such a composition is not inferior to the other representatives of the goods in this category. The ease of installation should be considered a positive feature of the material, due to which the processing of walls with foam can be performed without the involvement of specialists.In the sale of the assembly comes in a small volume of cylinders. According to consumer reviews, the composition after processing increases in size by 20 times.

- Polyurethane. The most demanded products among the presented types. Due to the popularity of the substance of its versatility. The material belongs to the group of two-component compositions. Technology of preparation of products requires mixing the ingredients before use. Compared with polyurethane foam foam insulation has a large increase in volume: the substance increases in size 40 times. In addition, in the structure of the formed layer there will be a greater number of bubbles, which has a positive effect on thermal conductivity.

Scope of application

In the light of a wide range of foam, presented today in the sale, it is necessary to have a clear idea about the use of a particular composition.

As for penoizol, it is recommended for warming frame structures. This composition fills the voids between the inside and outside walls, the wall and the plastic material, the base and the plasterboard sheets, as well as between the floor and the floor covering.Such a composition will provide reliable protection to the facade of the house from external factors, including rainfall.

Foam assembly is used when installing solid insulation materials, after which the same composition is used to seal the seams. Products will be useful in the process of arranging the foundation, as well as when working with a ceiling surface.

Polyurethane compounds, in addition to wall insulation, perfectly cope with the incorporation of various cracks in them. In addition, polyurethane foam is filled with voids during the installation of window blocks and pipes. With the help of this material is carried out insulation of the basement, attic. Two-component foam is purchased for processing the walls of houses of frame type.

Manufacturers Overview

You can buy foam for insulation in any building supermarket or on the market. On the shelves there are products represented by domestic and foreign manufacturers.

Among the having a range should be identified some of the most popular brands.

- Makroflex. Foam has excellent adhesion and uniform structure. But becausethat this brand is far from new in the construction market and enjoys well-deserved popularity due to the high quality of the compositions, fakes are quite often on sale.

- "Moment Installation". The composition has a rather dense structure. Completely stiffened surface perfectly gives in to coloring.

- Soudal. Products are notable for the lack of smell. In addition, the foam does not contain toxic substances, so it can be classified as "eco". However, the polymerized composition requires mandatory protection from ultraviolet radiation.

- Penosil. It has a small indicator of secondary expansion, but there are limitations in the scope of application: this foam is not recommended for processing walls outside

- Titan The composition is inherent in good density, foam does not shrink.

Recommendations for use

For a simple man in the street, many professional techniques relating to working with foam for base insulation on an industrial or smaller scale may not be known. However, there are a number of mandatory rules relating to the performance of work of this profile.

The following general recommendations should be highlighted:

- products should be bought only in specialized departments in the quantity required for insulation, since the same material should be used during the work;

- since the foam has inherent properties of sealing surfaces, in the course of work on the treatment of internal bases, a good level of ventilation should be ensured in advance;

- for work with a substance, it is necessary to purchase all the necessary personal protective equipment;

- Before proceeding to the treatment, it is better to test the material for the level of increase in volume.

When working with trimmed walls, special holes are made in the material for the hose of the apparatus through which the space is filled. Introduction of foam is performed from the bottom up. At the end of the work, the holes must be sealed in order to exclude the exit of the compound through them. After applying 30 cm of foam, it is necessary to check the level of expansion of the substance. If there is not enough material, foam is introduced into the cavity again.

Upon completion of work, you must wait for the material to completely harden. During this process, a very important point is the ventilation in the room - fresh air must continuously circulate inside.

When the further finishing does not imply fixing from the top on the composition of any additional material, plaster can be applied on the leveled surface of the foam. The resulting base will be quite durable, so the use of materials from above is not mandatory.

Foam for thermal insulation is not the cheapest option for surface treatment, however, the reliability and quality of the formed layer of insulation justifies the investment.

In the next video, you will see how to insulate the wall yourself with mounting foam using a homemade device.