Polyurethane foam: properties and specifications

Sealing (closure of slots and openings) is performed by various specialized compositions. But the technical characteristics of polyurethane foam favorably distinguish it against the background of other mixtures of the same kind. Know the information about them is necessary for the most accurate selection of suitable recipes.

Special features

A product such as polyurethane foam mounting sealant is placed in cylinders, from where a special gas pushes it out. In most cases, this role is fulfilled by propane-butane, the same gas forms foam bubbles. There are one-component and two-component mixtures, and there is also a division into specialized and domestic varieties. At home, use the adapter in the form of a tube,professionals prefer to use mounting guns.

There are different options for the seasons:

- for the winter period;

- during the summer months;

- universal option.

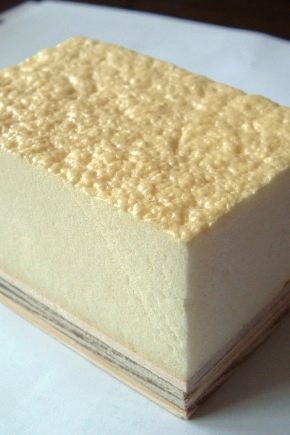

Polyurethane foam was created in the late 1940s. The chemical composition is relatively light, the composition includes suspensions of hydrogen and oxygen, as well as liquid substrates. Expansion of the foam due to the chemical processes occurring in it helps it to penetrate into the cavities and distant corners that are unattainable by ordinary methods. The foam product is quite dense. It adheres well to many other materials and is resistant to tearing or compressive forces.

Application area

Polyurethane-based sealant is excellent for processing various materials - glass, stone, plastered surfaces, metals.

It cannot be used when working with:

- silicone;

- teflon;

- polyethylene.

The role of polyurethane foam is great when it is necessary to install doors, window frames, window sills and some other details. It is used in furniture production, in the production of synthetic fabrics and household equipment. Polyurethane is used in the production of refrigeration systems, lycra and spandex.

The main purposes of using foam are:

- filling gaps in roofing cakes, heating and plumbing, doors and boxes;

- attaching insulation to the walls;

- improvement of noise protection in places where household appliances work;

- increasing the density of partitions in homes and in vehicles.

Advantages and disadvantages

Foam material to use to achieve any of the goals is much easier and simpler than most other materials. It is safe for humans and pets, mechanically strong and almost does not cause allergies. Use the professional version is good, because the guns significantly increase the penetrating power of the material. But the domestic variety is much better suited for the production of minor works. Even when the atmosphere around is very humid, the temperature is constantly changing within wide limits, the foam stably transfers such effects.

As shown by expert studies, 1 cm of polyurethane sealant after curing retains heat to the same extent as 1.5-1.9 cm of polystyrene. For mineral wool, this ratio is 1.8.Using just one cylinder of typical capacity, two or even three windows or one door are easily installed (if it is not exactly gigantic in size, of course).

In addition, the speed of work grows noticeably, which is important for both professionals and amateurs. Sometimes foam is even used to form various decorative shapes.

Tips for choosing

Even if the package contains the marking GOST, this is still not enough. When using it is necessary to look, whether the pressure of the ejected mixture is the same, whether it is produced evenly. It is unacceptable to use a sealant that “floats” immediately from the desired surface. Small cells make the created layer stronger, it is easier to tolerate high humidity and more effectively adheres to various surfaces. When evaluating it is impossible to be guided by the recommendations of the sellers and descriptions in the technical documentation, you need to carefully read the real consumer reviews.

Recommendations for use

Any foam, regardless of the form of delivery (in cylinders or barrels), Terms of use are the same:

- wear gloves before using sealant;

- close only the slit size from 10 to 80 mm;

- the surface to be treated is moistened in advance;

- the balloon must be shaken, turn the bottom upwards;

- vertical slits are sealed with a “pillow” created from the bottom up;

- It is necessary to wait for a set of strength at least 8 hours after application

- Considering the harmful effects of ultraviolet rays, plaster, putty or other sealant is applied on top.

Touching the foam layer to the total hardening is unacceptable. Otherwise, the production of the barrier layer will be disrupted or it will slowly pick up the target density. Strongly avoid contact with sealant in the eyes and mucous membranes! Even if it is immediately removed from there and the affected area is thoroughly rinsed with water, it is advisable to seek medical attention.

Vertical seam should not flow. Solidified sealant layers should be stable in size. If polyurethane foam is classified as waterproof or impervious to the action of various substances, only protection for a short time is guaranteed. It is recommended to evaluate the quality of the cylinder and its labeling, the integrity of the valves.Even inscriptions are important, because blurred, fuzzy texts, missing letters, distorted colors, the absence of labels or their unreadableness is a sure sign if not forgery, then marriage.

The temperature of the foam container should be carefully monitored. When heated by more than 50 degrees, it can explode.

About varieties

Tubular type - these are cylinders of the usual type, complemented by an applicator. Household sealants of this category have a density of from 20 to 23 kg per 1 square. m and presented on the market in a wide variety of forms and from many manufacturers. So almost all customers will be able to choose a suitable product for themselves. Pistol foam has such an important advantage as small re-expansion (in other words, it behaves very predictably, it is easy to estimate what kind of volume the frozen sealant will have). In addition, the professional type will harden faster and be more stable in terms of chemical and mechanical changes.

Single-component foam formulations expand the first time a lot more than the second. You can store them after purchase 12-18 months. The two-component mixture eliminates the surface moisture, is stored longer and differs in density from 30 to 40 kg per 1 square meter. m

“Summer” foam can be used at an air temperature of +5 degrees, and the cylinder must be heated to at least +10 degrees. Winter compounds due to special additives can harden at negative air temperatures. All-season reagents are allowed to use when the frost is up to -10 degrees, and the balloon itself must still be heated to +5 degrees.

additional information

If the foam mixture has a limited expansion, it is less suitable for filling cavities. At the same time a very thick and almost insurmountable for the harmful effects protective layer is formed. Compared to alternative solutions, foam sealing can significantly reduce waste. It is best to cut the applied sealant in the first 45 minutes after installation; skipping this period, you will have to either leave it as it is, or dull the tool.

If it is written on the cylinder that its capacity is 1 liter, there is really only 0.75 l of sealant inside. The remaining volume is displacing gas. The action of moisture penetrating into the foam layer leads to its expansion by 0.5-3 times. The final hardness left the tank mass gains after 24 hours.The temperature should be at least +5 degrees, maximum +35 degrees, and the relative humidity of the atmosphere - from 60%. In the specified temperature range, it is desirable to use any foam, because deviations from it are only permissible, but do not guarantee optimal properties.

Not only plaster, but also wallpaper can be applied to the foam layer. They will remain resilient and will not shrink. Foam protection perfectly manifests itself not only at the pipe inlets into the walls, but also at the joining points, while cornering. It will help fix the decorative panel for the walls, insulating and insulating coatings. Getting acquainted with the instructions about the release of the sealant from one cylinder, it is useful to take into account that these data refer to ideal situations when temperature and humidity are normal, and foaming is not difficult.

In actual work situations, the volume of a product that will saturate a gap or pass into a hidden cavity may even be 2 times less than the promised mass. Therefore, wise consumers always check how heavy the bottle purchased is and will not take it if the manufacturer’s coordinates are not indicated.Assembly adhesive foam is obviously not the product that can simultaneously stand out for quality and cheapness. If possible, before applying it, remove the slightest contamination.

You will learn more about polyurethane foam and its features in the next video.