Hilti guns for foam: device and application

Foam gun is one of the most essential tools for repair. The foam itself is a dense mass in a cylinder under pressure and allows, for example, to fill the space between the apertures of the walls or is used when installing windows. This substance quickly hardens and prevents the appearance of cracks due to tightness. But also foam has excellent thermal insulation properties, moisture resistance, durability and non-toxicity. All these characteristics are simply indispensable in construction.

A large number of firms and models of pistols are represented in this market segment. The article will discuss the popular brand Hilti.

Special features

With the help of foam guns, work can be done as accurately as possible, evenly applying material.

Hilti foam, like pistols, is also very popular and has many positive recommendations from users.This brand is an international group of companies, which mainly specializes in the production of drills and perforators. Pistols Hilti - a high-class tool, belonging to the average price category, and the class of equipment - professional.

CF DS-1 Model considered the most reliable tool. When used, the material consumption is very economical due to the adjustment. Even if this equipment falls, the foam container will remain intact, since the base of the equipment consists of quality material.

The average price for CF DS-1 is 3.5 thousand rubles and has a 2 year warranty.

Among Hilti products there are dosing tools for fire chemistry. They have a high degree of reliability and durability. Such guns are made of high-strength materials and are designed for daily use.

When working with equipment it is necessary to comply with certain security measures:

- do not send it to people;

- penetration of foam into the eyes is very dangerous;

- it is necessary to observe the temperature of the storage device, as it is under high pressure;

- hit of direct sunshine and fire - is inadmissible.

Advantages and disadvantages

At the equipment of this brand pluses considerably outweigh the minuses, therefore we will consider both.

Benefits:

- very small weight;

- comfortable grip;

- there is a lock against accidental pressure;

- work in inclined situation is possible;

- long service life;

- thin nose;

- can be disassembled, making it convenient to rinse if necessary;

- suitable for fire fighting foam;

- quick cylinder change.

Let us analyze in more detail the advantages of the Hilti CF DS-1 pistol. Thanks to the thin spout, comfortable and easy penetration into the most hard-to-reach places is ensured. Work in the lateral position is provided by a sealed system. The body is made of high quality reinforced plastic, which clearly confirms the long-term operation of the tool. Equipped with a special lock from unwanted pressing, which is in a very small number of pistols. Its presence in Hilti is a definite plus.

Despite the fact that the tool is made of plastic, it is several times better and more durable than metal counterparts.

And also when working on a stepladder or other unstable surface use equipmenteasily with one hand.

Among the shortcomings can be noted a rather high price. As you can see, the minus of the gun is quite insignificant. The cost is fully paid back by a long service of the equipment and the quality of the work performed by him.

Device

To work with a gun, you need to know its device, it will help not only to be confident in the chosen model, but also ensure proper operation without breakdowns.

The design of the gun for mounting foam is quite simple and straightforward:

- The barrel of the device is a tube, at its ends there are special valves that ensure that the gun fulfills the main task by creating a high pressure. That it contributes to the outflow of foam. The barrel itself is covered with Teflon, is collapsible in this model and consists of two parts.

- For ease of use there is a handle (in Hilti CF DS-1, it is ideal for the largest hand) or the central support of the entire instrument. There are special finger grooves on it, which makes the work easier. In this model, it is also anti-slip.

- The holder for fixing the cylinder, in other words - a universal adapter.This part of the device has the largest load. It is suitable for various cylinders, even the production of other factories.

- The trigger or adjustment lever, which allows you to control the amount and feed rate of foam used.

- And also there is a fastening part of the gun, it is responsible for the location of the cylinder. As a rule, it is made in the form of a nut, and thanks to it you can remove the barrel.

Application and use

The scope of pistols and, directly, foam, is very wide. The installation of doors and windows is used to seal joints and crevices. When working with roofing structures, passages around pipelines, a gun will also be needed for sealing. This is a very small list of works that use foam and gun. Currently, no repairs are complete without this device.

The principle of operation of the equipment is quite simple, and anyone can handle it, even the one who first picked up a gun.

Before using it is necessary to pay special attention to the fact that the balloon with foam should be at room temperature for about 12-14 hours (and even better).After which it is necessary to shake well for about half a minute. Next you need to properly charge the gun, following the instructions:

- Position the bottle upside down on the adapter. A sizzling sound should appear.

- The screw responsible for the adjustment must be turned to check counterclockwise and the adjustment lever must be pressed in order for the mass to start flowing.

- After that, you should check the texture of the foam.

- It is necessary to moisten a working surface with water, so foam will harden better.

- The foam is applied in layers, evenly, and the tip of the gun during work must be completely immersed in the material.

After completion of the work to remove the cylinder from the gun is optional. Thus, the foam can be stored for several weeks. If the break between procedures is quite large, then you need to clean the gun according to the following instructions:

- the cylinder must be unscrewed;

- instead, a cylinder is installed with a cleaner;

- in this state, you need to leave the gun for about 15 minutes;

- the cleaning fluid is dispensed with a lever and the canister is removed.

With regular use of the instrument, such cleaning should be done once every 2-3 months.

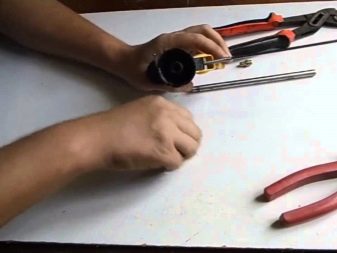

To disassemble the tool, you must first unscrew the spout. This can be done with pliers or a key. Then the tube is unscrewed in the same way. If you need to remove the front cover from the feed barrel, then you need to use a screwdriver and then carefully unscrew the barrel itself.

To carry out the analysis for cleaning yourself is not at all difficult. To collect it is necessary to perform the same procedures in the reverse order.

Details about the Hilti gun for foam, and tips on how to use it, see the video below.