How to choose a gun for foam?

Polyurethane foam is used in construction in order to quickly fill the space between the wall opening and the frame. This material is indispensable in the process of installing metal-plastic windows, since it is thanks to him that he manages to guarantee the integrity of the entire structure. For the application of the substance is usually used a special gun, which is presented on the market in a large assortment.

Special features

Polyurethane foam is a curing substance that prevents the formation of cracks and allows you to fix certain building elements in the structure. The only drawback of foam is the fact that it is poorly supplied from a can, so for these purposes it is best to use special pistols.

If repairs are carried out at home, then a cheap gun would be the ideal solution, but for permanent use you need to purchase a professional version.

The enormous popularity and demand for this device is due to a number of advantages, among which are the following:

- the ability to accurately dispense the material used;

- ensuring economical consumption of foam and high-quality sealing;

- the ability to use cylinders not immediately, but some time after the opening.

Kinds

There are a huge number of varieties of foam guns on the modern market. The most popular pneumogun with a Teflon coating. This option is great for spraying small areas. Depending on the frequency of use of guns for polyurethane foam emit amateur and professional options.

A distinctive feature of professional cylinders is that a special gun is used to extract the foam. But the domestic options just include a plastic pistol nozzle, which serves as a pistol.

Options for pros have good coverage and durability. Because of this, they can be used on a regular basis and not be afraid that they will begin to lose their properties. The main disadvantage of household guns is that such a cylinder must be fully used within a few hours after opening. But the use of the professional version makes it possible not to worry about the safety of this building substance.

The use of a domestic pistol greatly increases the amount of foam consumed, since such devices cannot boast the presence of an adjusting screw fixing the rate of foam extraction. In other words, if you compare the costs of an amateur version and the costs of buying a professional device, then there will be no significant difference. That is why it is recommended to buy special guns for mounting foam, which are arranged accordingly.

Criterias of choice

The modern construction market includes a huge number of foam guns, so that everyone can choose the most optimal option for themselves.The choice of the device should be approached with all responsibility, because it will depend on this circumstance whether it will fully fulfill its obligations.

First of all, it is necessary to pay attention to the material that was used in the process of manufacturing a gun for foam.

The design of the unit can be made of the following materials:

- Inexpensive plastic. All low-end models of pistols are equipped with just such plastic. Such mechanisms can not boast of reliability, so using a plastic gun for a long time will not work. In addition, the work performed with the help of such a device is not of high quality.

- Durable plastic that is resistant to mechanical damage, shock and scratches. In terms of quality characteristics, such models are not inferior to metal, but at the same time they can boast a long service life, ease of use and reliability. The gun can be easily disassembled and cleaned.

- Teflon-coated metal pistols. Such products are characterized by high cost and are usually intended for professional use.The distinctive advantage of such models is the ease of cleaning them from the remnants of foam.

You should also pay attention to the ability to disassemble the mechanism. Budget varieties are usually monolithic devices, so after the first failure they can be discarded. But collapsible varieties can be easily repaired by replacing broken parts. Even despite the high cost, collapsible guns for mounting foam are more cost effective as they can be used much longer.

The normal operation of the device also depends on the tightness of the valves. That is why before buying a pistol is recommended to check it. It is best to use for this purpose not the assembly foam, and the usual liquid for cleaning. It is necessary to simply screw the cylinder with the cleaner into the adapter, and then pull the trigger a couple of times.

It is worth making sure that there are no liquid leaks. The cleaner should be sprayed under high pressure, rather than just flowing out of the barrel. We leave the gun and again check its tightness after a day.If there is no problem with tightness, it will be possible to spray the substance under high pressure. But if the liquid just flows, and will not fly out, then the purchase of such a unit is best given up, since it will not be able to qualitatively perform its functions and last for a long time.

Important when choosing also has the frequency of use of the device. If you are going to use a gun only occasionally, then you can choose cheap monolithic models. But with regular use it will be more profitable to buy a professional version with a Teflon coating. It has a great price, but it pays off quickly enough due to the fact that you do not have to constantly change the guns.

If you buy a model from a specific manufacturer, then you need to examine the availability of spare parts. It often happens that, due to the lack of a certain spare part, it is not possible to repair the device, as a result of which the gun for the mounting foam becomes unsuitable for further use.

Principle of operation

Before you buy a device, you must carefully study the features of its design.Only in this case, you can buy a mounting gun, which will fully fulfill its obligations. And this construction device got its name due to the similarity with handguns.

They have a huge number of common external and internal nodes that are similar not only in appearance but also in purpose. First of all, we are talking about the trunk, through which the mounting foam comes out. The liquid substance literally falls out under enormous pressure, after which it is polymerized into a solid.

In addition, the design of the gun for mounting foam includes a trigger, which is a trigger. It is the trigger pull that activates the whole mechanism, as a result of which foam is released from the balloon. The gun also includes a handle that can be made of plastic or metal. It is necessary to hold the tool in your hand.

During the purchase process, it is imperative to hold the gun for the foam to ensure it is easy to use. The handle can be of various shapes, and the choice in this case depends solely on the personal preferences of the master.

Some expensive options for foam guns are equipped with a special mechanism to control the supply of foam. We are talking about a fixing screw, thanks to which it is possible to control not only the speed of the output of the mounting foam, but also the volume of the produced substance. Before you start using a cylinder and a construction gun, you must maintain the cylinder itself for at least 6 hours in a room with room temperature. In addition, before use, it is necessary to shake the bottle as much as possible, after which you can proceed to remove the protective cover.

The exhaust mechanism should be set in motion as smoothly as possible by pressing the trigger. Otherwise, you can free up a huge amount of foam, which will fill the opening not only from the inside, but also from the outside. It should also be taken into account that the assembly foam tends to increase, therefore, it is not necessary to fill the gap with it completely. And the direction of movement of the foam is set by the operator in whose hands this building tool is located.

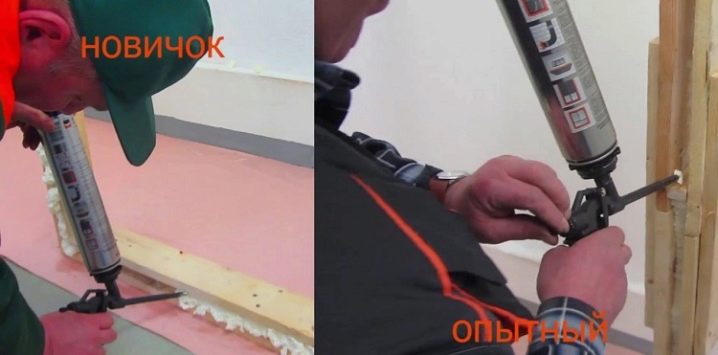

As for the speed of output and the amount of materials, this circumstance can be adjusted using the fixing screw.It should be noted that this circumstance depends on the experience and skills of the master who controls the tool.

Standard foam gun models come with a variety of accessories and nozzles. Most models on the market today come in cardboard or plastic packaging, which also includes several attachments. They can be stored in the same box.

To perform the work, most models are equipped with the following types of nozzles:

- The conical shape, which is necessary in order to fill the narrowest cracks and cracks. This nozzle allows you to easily reach the most inaccessible places.

- The extension cord, which is a flexible tube made of polymeric materials. This accessory is also indispensable in the process of working in hard to reach places.

Most of the nozzles offered are reusable, so that they can be used for a long time. However, after each application, they must be cleaned with the help of acetone or a special tool that may be included in the device.Otherwise, the mounting foam will dry completely, and the tool will become unusable. If the liquid was not removed in a timely manner, and the foam had time to harden, then it will have to be mechanically cleaned. However, to do this, it will be necessary to wait at least a week for the substance to completely dry and seize.

For spraying, you can use special nozzles that are included.

How to use?

In order for the work carried out to be of high quality and durability, it is necessary to properly use the gun for the mounting foam. Careful attention in this process should be paid to the preparatory stage, the essence of which is to shake a can of foam at least 20 times within a minute. Only after that it will be possible to remove the cap and turn the adjusting screw on the gun itself.

As a result, the valve closes, after which it will be possible to connect the container so that it is under the gun. Adjusting screws are used to control the speed at which the foam exits.Pull the trigger should be as smooth as possible, since this is what allows you to control the speed of the protrusion of the foam.

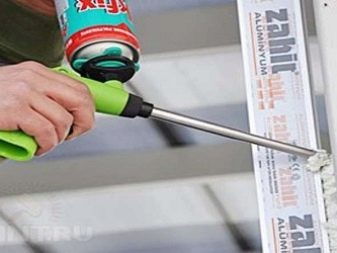

The basic rule of using a gun for foam is that the cylinder itself must be on top, above the gun and only in a vertical form. Only in this case, the gas can push the contents of the tank, otherwise it can spoil the construction tool and make it unusable.

Sometimes it happens that the barrel of a pistol is too thick and because of this it is impossible to penetrate a hard-to-reach place. In this case, you must use special tubes, which come complete with a building tool.

In the process of work, it is necessary to be as attentive as possible, since if the foam hardens and the work was carried out poorly, then the process of their elimination will be quite difficult and lengthy. After using the gun, the nozzles should also be rinsed immediately, since after solidification of the substance it is extremely difficult to cope with this matter.

Tips and tricks

When working with a gun for mounting foam, there may be some problems that are directly related to the inconvenience of using the design.It should be ensured that the cylinder is always upright with respect to the building tool. Otherwise, this greatly complicates the use of the tool and may cause its breakage. And to eliminate this drawback, it is often necessary to resort to using a special tube, which is designed to lengthen the gun.

However, this has a negative effect on the comfort of using the unit, since the operator has both hands occupied and he cannot respond quickly.

Manufacturers

On the modern market there are many companies that specialize in the production of foam guns. The products of each company have their own distinctive features, so it is recommended to pay close attention to all aspects. Lovers should choose the best devices from well-known brands that have managed to prove the reliability and high quality of their products.

The most popular today are the following manufacturers:

- Kraftool. It has been on the market for many years and produces reliable devices.The company's catalog includes both amateur and professional options.

- Soudal. This manufacturer produces guns for polyurethane foam, which are made exclusively of metal. Most models boast a Teflon coating that ensures their durability and reliability.

- Matrix. The company's catalog includes a variety of devices made of aluminum alloys. The handles of each model are made of plastic, and the kit includes interchangeable nozzles.

- Ultima - is one of the most famous manufacturers of building tools. The company's range does not include plastic-coated devices, but there are quite a few metal options. A distinctive feature of Ultima pistols is that they provide an opportunity to precisely control the amount of foam used.

- Blast hard produces high quality metal devices, characterized by Teflon-coated.

- Hand tools - professional pistols with a metal body.

In the domestic market, pistols for Varyag polyurethane foam are very popular. A distinctive feature of the model is that it provides for removing the spout by twisting the nut. This allows you to quickly clean the device.The manufacturer paid close attention to the materials used. The cylinder mount is made of brass, which has a positive effect on the number of fixings of consumable items.

One of the most popular models in the construction market is the Matrix 88669. It boasts a durable and attractive body and Teflon coating. In addition, the device is famous for special coating, which to some extent resembles a non-stick coating on the pan. It is thanks to him that the foam is firmly glued in the supply tube.

The developers have done everything possible to maximally simplify the process of using this gun for foam. After application, simply wipe the device and clean the spout with a special nozzle. However, this requires careful action, since Teflon is extremely easy to scratch, so any irresponsible attitude can spoil the inventory, which has a great price.

The gun is equipped with a durable and smooth trigger, the fingers from which do not slip while pressing.Metal was used for the production of each element, thanks to which the structure boasts durability and reliability.

Among the main advantages of the model are the following:

- cleaning is quick and easy with a Teflon coating;

- the grip is renowned for its convenience and provides good protection against pinning;

- the case is made of solid copper, which makes the device resistant to mechanical stress.

Professionals will appreciate the gun for the foam “Hilti cf-ds1”. This model is considered one of the most optimal tools for professional use. In appearance, it is quite reminiscent of the firearms of the same name and has a dense body.

The trigger is equipped with an additional slider, which is designed to block a random press. Because of this, you can not worry that the foam will come out while the gun is on the belt or in the luggage compartment of the car.

"Hilti cf-ds1" boasts a thin spout, at the end of which there is no nut. This makes it possible to stick the tip almost anywhere.This model can also boast its integrity. The tool body is made of reinforced plastic. The only drawback of this foam gun is that its body does not disassemble. If such a monolithic structure breaks down, it will not be possible to replace a specific part and use the device further.

Among the main advantages of "Hilti cf-ds1" are the following:

- small weight, which greatly simplifies the transportation and use of this construction tool;

- the presence of a blocking slider, which does not allow accidental extrusion of foam;

- a large handle that will be comfortable even for a person with a large hand;

- the ability to use the unit in the lateral position;

- foam is not allowed in the fall;

- durability - this model can be operated for at least 7 years.

One of the most expensive and professional models is the Matequs Super Teflon. Products of the Italian brand is famous for high quality, reliability and durability. A distinctive feature of the device is its unique design, thanks to which the mixture at the outlet is more plastic and of higher quality. Due to the unique scheme, the device works in any conditions.

In addition, the Matequs Super Teflon boasts a needle with an expanded diameter of 4 mm.that allows to fill up cracks in short terms. Despite its ergonomics, the handle is hardly suitable for people with a big hand. Among household guns for polyurethane foam, the model “Stayer Econom” is very popular. Its distinctive feature is reliability and durability. The developers have equipped the device with a special stainless feeding tube, which is simply cleaned and not scratched. The only drawback is that the tube cannot be removed for flushing.

The cylinder is secured with an aluminum grip, and metal is used to produce the trigger. Despite this, he descends smoothly and without any problems.

After the foam has been applied and all work has been completed, the barrel must be further treated with a cleaning agent. If this is not done, then in the future there may be problems with the permeability of the cleaning agent. The delivery system is characterized by the presence of a ball valve at the inlet and a special mechanism at the outlet.

One of the advantages of this model is a well-thought-out design, which ensures trouble-free use of the device and its durability.Due to its robust body, it copes well with mechanical damage.

Reviews

You can find a huge amount of reviews about every model of foam gun. If we say in general that all masters and amateurs agree that the use of such a construction tool greatly simplifies the process of filling the gap with foam. Masters advise the device from the company "Whirlwind" and other manufacturers, which are distinguished by a large handle. This provides a high level of comfort in the process of use and allows you to carry out all the work as quickly as possible and at a qualitatively high level. The rating of pistols depends, first of all, on the materials that were used to produce a particular model and how the unit is arranged.

Thus, the foam gun is a unique construction tool., designed to significantly simplify the process of filling the substance gaps and openings. The most important thing is to choose the right unit so that it can fully cope with the tasks assigned to it.

With single or rare use, you can give preference to amateur options, but for regular use it is best to buy professional models. It should be remembered that the monolithic options can not be disassembled, so if a breakdown occurs, repair will be impossible.

To learn how to properly use a gun for foam, see the following video.