Soudal polyurethane foam: characteristics and features of use

Extensive use of polyurethane foam due to its technical characteristics, as well as ease of use. Among the huge number of manufacturers of these products, Soudal products deserve special attention.

Specifications and properties

Foam assembly Soudal is made on the basis of a material with a high ability of adhesion of various surfaces. The sealing mix is made on the basis of polyurethane.

Curing of the foam occurs at a high humidity of 60% and a temperature of 20 degrees above zero. Already after 8-10 minutes, the upper film layer is formed. After approximately 25-30 minutes, the surface becomes completely dry. However, it should be noted that the rate of solidification increases depending on the size of the gap.

The hardened sealant has a dense consistency.Closed pores make up 80% of the entire surface. The density of the substance is 26 kg / m3.

Foam is available in cans, the volume of which is 300 ml, 500 ml, 750 ml. Professional foam can have a can volume of 1 thousand ml. It should be noted that with a volume of 300 ml, up to 30 liters of the substance can be obtained at the outlet. The volume of 500 ml cartridges gives up to 40 liters of the substance. If the volume is 750 ml, the output is up to 50 liters of the substance.

After hardening, the mixture is usually yellowish or greenish. Dark saturated color is a sign of the destruction of a substance under the action of sunlight.

Keep sealant in a cool place for no more than one year.

It should be noted that the extreme temperature limits when working with this material is a temperature from 5 to 35 degrees above zero.

Fire-resistant foam Soudal is characterized by versatility of application. Due to the presence of high temperature resistance in the solid state, it retains its properties at temperatures from minus 40 degrees to plus 90 degrees.

The material has special technical characteristics:

- high refractoriness;

- Bending strength index corresponds to 17 N / cm2;

- sound insulation is 58 dB;

- compressive strength is 3N / cm2;

- moisture permeability is 1%;

- bending resistance is 7N / cm2.

Professional and household foam differs in the type of valve of the cartridge into which the sprayer is inserted.

The sealant is produced using modern technologies and meets the existing quality standards. The presence of a certificate confirms the absence of impurities to the environment. With proper use of foam, there should be no crumbling processes, destruction.

Advantages and disadvantages

Among the indisputable advantages of Soudal products are:

- availability of options for use in the cold period, so in the heat;

- strength;

- elasticity;

- quick setting of the material;

- profitability;

- the possibility of applying not only for professional purposes, but also in everyday life;

- ease and simplicity of use is provided by convenient fastening of the gun in the opening of the aerosol container;

- environmental friendliness of the material;

- low shrinkage;

- no double expansion effect;

- surface distribution efficiency;

- high adhesion density;

- long service life.

The disadvantages include:

- the inability to work with materials made of polyethylene, Teflon, silicone, polypropylene;

- Fuzzy adherence to instructions may adversely affect the final result;

- when working with sealant it is necessary to follow safety rules;

- foam produced for winter time at a temperature of minus 10-15 degrees may come out of the cartridge in a smaller volume than that indicated on the package;

- does not withstand exposure to direct UV rays;

- material cost is slightly above average.

Despite having disadvantages, Soudal sealants are widely used in many countries around the world. The choice in favor of this product is based on the undeniable quality of this product and its long service life.

Assortment and selection

The manufacturer Soudal is best known for several popular products.

Soudafoam fr

A distinctive feature of this refractory mixture is the ability to prevent the spread of fire for up to 6 hours.

Soudafoam maxi Arctic

The so-called winter foam, which is distinguished by the fact that it allows you to work with the material at a temperature of 25 degrees below zero.

Soudafoam classic gun

Foam belongs to professional types.It allows you to work at temperatures from 5 to 30 degrees above zero.

Soudafoam maxi 70

In addition to high strength, adhesion, environmental friendliness, fire mixture has a fairly high fire resistance class, which is equal to B3.

Soudabond easy

A distinctive feature of this material is that it acts like glue. The substance is able to glue cotton wool, artificial material to the surface of concrete, metal, brick.

Soudafoam maxi sahara

A feature of this type of sealant is the ability to operate the material at temperatures from plus 40 degrees and above.

Soudafoam classic gun winter

Winter foam can withstand temperatures up to minus 10 degrees. It also has high strength properties, environmental friendliness, adhesion.

Makroflex 750

A distinctive feature of the sealant is the presence of a mixture of species for work in the warm and cold season. It can be used at temperatures from 5 degrees above zero to 18 degrees below zero. The maximum amount of material after expansion is 65 liters. Packing capacity is 750 ml. Sealant retains its properties in the temperature range from 54 degrees below zero to 100 degrees above zero.

Soudafoam Professional 60

Sealant has a high ability to connect with surfaces, environmental friendliness, accuracy of dosage.The volume of the mixture at the outlet is 60 liters.

Soudal Profil Pu Foam 625

Household one-component foam is easy to use, does not require special tools. The volume of the mixture at the outlet can reach 40 liters. Sealant has excellent adhesion characteristics, environmentally friendly, stable.

Soudal flexifoam

The specialty of the sealant is high performance, elasticity, fast hardening, bond strength.

To obtain the desired result it is necessary to choose the correct sealant. It is important to determine for what purpose foam is needed. Depending on whether the work will be done indoors or outdoors, select the appropriate type of sealant. But it is also necessary to take into account the temperature and humidity.

Features of use

Before you start working with sealant, it is necessary to carry out preparatory activities, which include a number of sequential actions.

- A can of foam is taken from a cool storage place and kept at room temperature until its temperature is the same.

- The surface on which the sealant will be applied is thoroughly cleaned of dirt, dust, foreign particles.

- For better adhesion of the sealant to the outer surface, it must be moistened with water.

- Before applying the sealing agent, it is necessary to remove the protective valve.

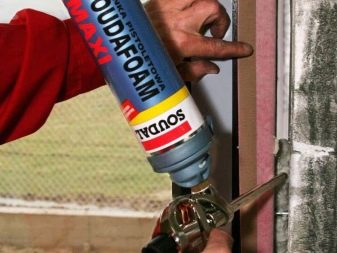

- If a pistol is to be used for work, then it will be connected to the cartridge.

- Spray needs to be shaken up.

- The substance is applied by placing the can upside down.

- After work, make cleaning, leveling the surface. Excess can be easily removed with acetone or any other solvent. After curing the foam, the stripping can be done only with the use of mechanical means.

There is a special 500 ml Soudal foam cleaner that is used to flush the sealant from glass, wood, plastic, metal surfaces. It is also used to clean the mounting gun, balloon valve. This substance effectively degreases the surface.

Due to its properties, the sealant is successfully used to fill voids, gaps:

- when warming any building structures;

- at installation of window, door designs;

- with the help of a sealant, fill the empty areas of the heating and cooling systems;

- due to foam reliable isolation of systems of pipelines is provided;

- the sealant provides reliable sound insulation, therefore, it is effectively used when installing any partitions or floors;

- foam is used in the construction of the walls of the bath, sauna, when laying fireplaces, stoves.

It should be remembered that when the sealant hardens, not all types have a yellow tint. The foam of the modern generation Flexifoam is blue.

It is important to note that the preparatory work is mandatory for any type of sealant, whether it is single-component or two-component, winter, summer or all-season foam.

Compliance with all rules of application of the sealant will allow you to get excellent surface quality for many years.

About what foam to choose for large windows, see the following video.