How to use the gun for foam?

For carrying out repair and construction works the set of various materials and tools is used. In this case, do not do without a gun for mounting foam. Using this device helps save a significant amount of time. Professionals from the above areas are actively using this tool for accurate application and cost-effective composition. Our article will talk about how to properly use this device.

Special features

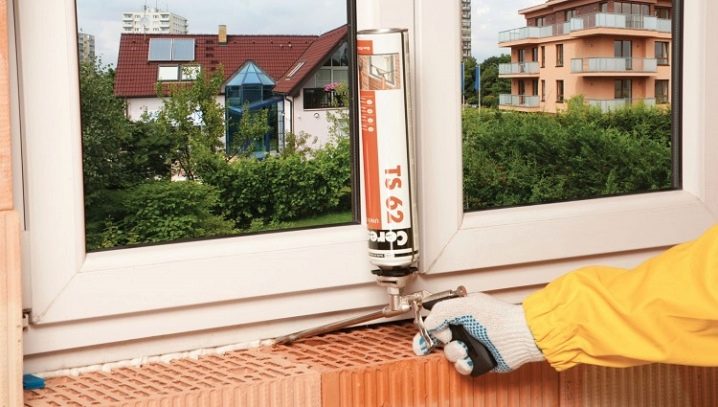

In the process of installing door frames, as well as PVC windows (metal-plastic models), it is impossible to do without using foam. Professionals say that applying the product by hand is very difficult.Special equipment allows for installation as soon as possible. Specialized stores offer a rich variety of different tool models for practical and convenient use of the composition. Distinctive characteristics have themselves foam cylinders.

Despite the rich range, most types of products are versatile. That is, for most pistols, almost all manufactured cylinders are suitable.

When working with foam it is imperative to think about personal safety.. Professionals strongly recommend wearing gloves and protect your eyes with building glasses.

You should also carefully study the instructions for the use of the product, especially if you do not have adequate experience in handling it.

Varieties of material

Before proceeding to the description of the process of using the gun, it is necessary to talk briefly about the consumables. There are two main types of it:

- Normal foam. Judging by the name, it is easy to guess that the first version is intended for universal use. This is an ideal option for those who decide to do the work with their own hands, without the involvement of specialists.Included with the barrel is a screw-on tube.

- Professional. The design of the product is designed in such a way that the cylinder can be connected to the gun. Packaging is equipped with a special tip.

Other features in the structure of the package is not available.

Professional polyurethane foam has increased wear resistance and durability. Its use is somewhat more complicated compared to the usual composition.

In addition to the features of packaging and technical characteristics, the assembly foam is divided into segments by seasons. There are three main groups: summer, winter and demi-season. (product can be used at any time, depending on weather conditions). This characteristic is very important if the work will be carried out outside the room.

Also on the cylinder manufacturers indicate the scope of products. The compositions are used for docking the pipeline, installation of entrance doors, insulation of structures and other works. Products differ in components in composition, practicality, durability and other aspects.

Device design

Let us consider briefly how this tool is arranged, and what it consists of.It is worth noting that its configuration is very simple. Despite the huge variety of models on the market today, they are all very similar to each other.

Consider the main elements of the device:

- A tube. This part has two tips, which are also called nozzles. The tube and nozzles have a different diameter, due to which the foam is fed under high pressure.

- Trunk. Without it, you can not do when working with deep holes. Its length can be 20 centimeters. There are two types of element design - collapsible and one-piece. The first option is much easier to clean after use.

- Adapter (he is a gearbox). The item connects the tank with the consumables with the mounting gun.

In the process of using this element falls the greatest burden.

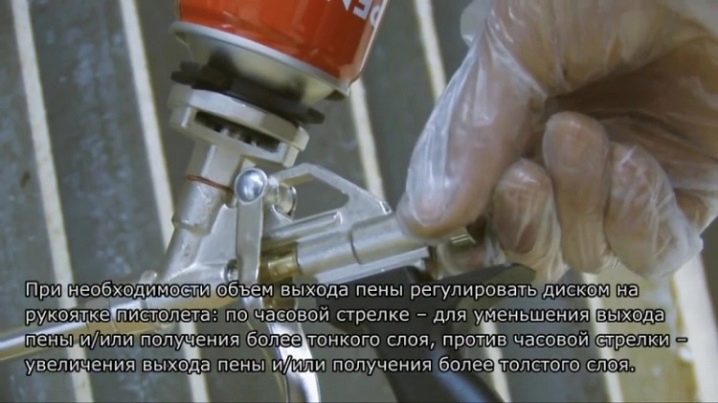

- Adjusting bolt. Judging by the name, it is easy to guess that with the help of a screw the required flow rate of the foam and its volume are selected. Very useful detail when performing major repairs.

- Fasteners. This part is responsible for placing and fixing the can inside the gun. It looks like a regular nut.

- Adjusting lever. This mechanism is designed to maintain control over the speed of the output of the consumption resource, depending on the force of pressing.

- Handle. The central element of the support, acting as a lock for the remaining elements. For its manufacture using metal or heavy-duty plastic. In order to increase user convenience, special recesses for fingers are applied to it.

Using the instructions for the device, even a beginner can work with the instrument.

The working process

Charging

Each barrel has a protective cap for hermetic storage of consumables. Before using it, it is necessary to remove and insert the cylinder inside the device holder. Remember the basic rule - during operation it is necessary to keep the container upside down (i.e. the holder should be at the bottom, like the handle, and the adapter should be at the top).

Install the container in the design of the gun is not difficult. In the process of screwing it is necessary to hold the tool with one hand, and the second to install the balloon with gradual rotational movements.

To make the composition uniform, the vessel must be shaken. It is desirable to do this in the standard position (handle on top).

You need to spend about 15-20 shocks.

Foam application

Before you apply the foam to a specific area, it is necessary to moisten it. Moisture is necessary for swelling to make this process faster and more efficient.

The tip goes to the seam. Pull the trigger gently and carefully, without sudden movements and jerks. In this case, the possibility of breakage of the trigger will be minimal, and the quality of the foam at the exit is higher. The hole is filled with material completely. During operation, make a nozzle movement from side to side, in the form of a zigzag.

Use the adjusting screw to change the amount of foam that is applied to the barrel. The volume depends on the size and depth of the seam.

So that the composition does not lose homogeneity, do not forget to shake it from time to time.

How to replace the balloon?

Changing the capacity with foam is a simple process that does not require special knowledge, exercises, preliminary preparation and other manipulations. Sooner or later, the foam ends and you have to change the tank to a full balloon. The replacement procedure is as follows:

- The barrel of the device must be sent to a bucket or other deep container.

- To get rid of the residual consumables, pull the trigger and wait until the foam remains.

- Next, turn the device so that the handle was on top, and simply unscrew the empty container.

- Liquid special composition should thoroughly clean the place of attachment and install a new vessel. The device is now refilled and can be used again.

Completion of work

As soon as the repair work has come to an end, the adjusting screw should be tightly closed in order to prevent oxygen from reaching the foam as much as possible. If foam remains in the tank, and the next application is planned for the near future, then it is not necessary to remove the incomplete balloon. On the contrary, experts recommend leaving it inside the instrument. In this case, the foam will not dry out due to being under constant pressure.

Before the end of product use, the nozzle tip should be treated with a special liquid. This procedure will prevent the drying resource from drying out. Subsequent application will be much easier and more comfortable, without mandatory cleaning before use.If the old cylinder is empty, and the new one is not at hand, it is necessary to remove the bottle, carefully clean the construction pistol and leave it for storage until the next use.

How to clean the tool?

Many people mistakenly believe that the procedure for cleaning a gun is optional and moreover meaningless. However, experts from the field of repair strongly disagree with this statement. Removing foam, frozen over the entire length of the barrel, is a complex, time-consuming and problematic process.

In order not to face this problem, it is necessary to clean the device immediately after the completion of repair work.

To begin with, the barrel should be turned in the opposite direction. The container with the expendable resource is unscrewed, and instead of it a detergent is placed in the holder. Push the lever and wait until the tube is filled with cleansing composition. This procedure should be given from 10 to 15 seconds, then the agent is removed, and repeated washing is carried out.

When removing the container with the solution, you should pull the trigger to clean the device from its remnants. When cleaning is completed, tightly tighten and lock the adjusting screw until it stops.

Keeping the instrument clean will keep its appearance and prolong its service life.

You can find out how to replace hard-to-reach places with a gun for polyurethane foam by watching the following video.