Two-component tile adhesive: features and specifications

Today it is impossible to imagine carrying out internal finishing works without the use of tiles. For high-quality masonry and in order to avoid alterations, it is very important to choose a good tile adhesive.

Two-component compositions are considered among the best for laying tiles in different conditions. Most often, such compositions are sold in convenient building buckets.

What is a two-component adhesive

Two-component tile adhesive is a high-strength compound, usually consisting of a hardener and polyester. It is mandatory in the formula of such adhesives contains improving synthetic additives.They are mineral compounds and plasticizers, giving the composition special physical and mechanical properties, due to the increased degree of plasticity of the mass, as well as the shelf life of the solution for work. During the mixing of the components, a polycondensation reaction takes place, resulting in the solidification of the solution. This composition is applicable for interior and exterior tile work..

There are polyurethane, epoxy and epoxy-polyurethane tile adhesives. Polyurethane compounds are considered the most flexible - they retain elasticity in all conditions. Epoxy glue is ideally suited for finishing industrial premises using a variety of chemicals. Epoxy-polyurethane compositions are similar to polyurethane, but have high strength.

Basic properties and characteristics

- High adhesion, that is, the quality of gluing. Measured adhesion ability to withstand the load at separation.

- High content of binding components and, as a result, excellent frost resistance, as well as a good degree of resistance to high temperatures.This property allows the use of tile adhesive in unheated rooms, on the street and in places with high temperatures.

- Water tightness and, as a result, long service life of a tiled laying.

- There is the possibility of using glue in the conditions of vibration, that is, on stairs, in elevator cabins, on columns.

- Two-component glue can be applied to materials of different structure, for example, plywood or cement-bonded chipboard (DSP).

- Double shear strength compared to conventional compositions.

The disadvantages of two-component adhesives

- High price;

- Sensitivity to non-compliance of the proportions of the ingredients;

- The difficulty of removing from the tile after drying.

Manufacturers

Litokol

The company produces two-component reactive tile adhesive. It provides excellent reliability of adhesion tiles with the base. This adhesive is suitable for laying not only on familiar bases such as concrete, but also on plastic or wooden surfaces.

In addition, this manufacturer produces reactive two-component adhesive LITOELASTIC. It is a highly elastic adhesive composition for outdoor and indoor wall and floor cladding, as well as for waterproofing measures in rooms and buildings with high humidity. The composition of LITOELASTIC does not shrink after hardening, is very simple to prepare and versatile in use..

Mapei

The Italian company produces polyurethane mixtures, with which it is possible to professionally glue tiles of different parameters. The main components of the two-component emulsions are isocyanate hardener and synthetic fillers, which enhance the adhesiveness of the solutions.

Two-component polyurethane adhesive for tiles Mapei Keraastic T is popular. It is suitable for laying tiles on screed, plaster, concrete, asphalt, wood, metal base, reinforced polyester, asbestos-concrete, gypsum and gypsum cardboard.

If tile laying with Mapei glue was carried out on the floor, then you can walk on it after 12 hours.

Ceresit

Ceresite is one of the most well-known construction mixes. Glue products of this manufacturer is known as moisture and frost. Due to the inclusion in the formula of mineral components and polymeric compounds, polyurethane does not react to strong temperature changes and high humidity (even over 70 percent).

For example, a two-component adhesive for ceramic tiles Ceresit CU-22 can be applied on a deformed substrate, with high temperature and humidity during work, both on the inside and on the facade of the building. Among its advantages are properties such as resistance to chemical attack, high strength, water resistance, lack of solvents in the composition.

Two-component adhesive Ceresit R-710 can be used for laying tiles made of rubber, quartz-vinyl and other unusual materials.

Kiilto

The Russian company produces a two-component tile adhesive based on polyurethane Kiilto PL 250 in the absence of a solvent. Such glue is usually used for sticking ceramic tiles, insulation materials, polyvinyl chloride, polystyrene and other materials.

This composition can form a strong, but at the same time plastic seam. There is the possibility of work at low temperatures (+ 5 ... +10 degrees Celsius), but the freezing time in this case is extended.

The main principles of working with two-component adhesive

Working with a two-component composition is not difficult.For high-quality masonry need a special spatula.

The procedure is as follows:

- The work surface must first be cleaned from dust, dirt, debris, remove burrs and roughness, and also dried.

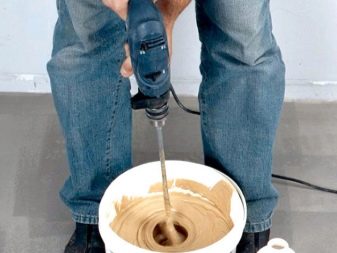

- Before applying the composition must be carefully moved to obtain a homogeneous consistency.

- The elasticity of the mixture should be such that it can be stretched without the formation of cracks, hiding small deformation errors of the base.

- Glue on the working surface is applied with a spatula. The layer should not exceed 10 mm. Also for perfect tile laying it is necessary to observe the uniformity of the applied adhesive layer.

- Excess mortar at the joints is removed with a soft cloth, pre-moistened with alcohol.

- It takes 1-2 days to set the glue.

It is important to clean the tools and clothing soiled in two-component glue before the mortar solidifies.

Possible errors when working with two-component adhesive

- Application of the composition on a wet surface. In this case, there is a high probability of a capillary rise of moisture, which is destructive for the laying.

- Packaged components have an optimal ratio to each other.Self-measuring and weighing the ingredients can lead to a violation of technology.

- Work with two-component adhesives is not recommended at too low temperatures.

Advice on working with two-component adhesive is waiting for you in the next video.