Fire-resistant drywall: types and properties

Gypsum plasterboard is a safe and reliable building material that meets high fire safety requirements. This versatile material for interior decoration is often used by experts in the field of construction, thanks to fire resistance, mechanical strength, ease of use, reliability. On the modern market, you can purchase various modifications of drywall. They differ in technical characteristics, scope, marking and tone.

Features: composition and properties

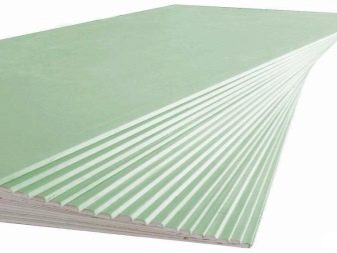

Fire-resistant drywall consists of two layers - gypsum and cardboard. Both layers are impregnated with special substances that allow to withstand from 25 to 60 minutes of direct fire.Even when exposed to flame, the material does not distribute smoke and does not burn. It is possible to distinguish types of gypsum cardboard by color marking. Moisture-resistant material is green, simple - gray, fire-resistant has a mark of red or pink.

The main feature of GKLO is that the most dense coupling is provided between the layers of cardboard and plaster.

Together with the impregnation of special non-flammable compounds, this prevents the penetration of oxygen into the sheet during ignition and prevents the destruction of the material. The difference between the varieties is in the composition and production technology of the gypsum layer. In the manufacture of plaster mass, it is reinforced with fiberglass-based reinforcing threads. The length of the threads is from 4 to 30 mm. They retain their structure, do not collapse under the influence of high temperatures. Reinforcing threads are the skeleton that keeps drywall from being destroyed during a fire.

For the production of gypsum special chamotte clay is used. When exposed to high temperatures, it is sintered, so that the sheet of the product does not crumble.The cardboard and the plaster layer are bonded to each other with the help of special adhesives, which act as a reinforcement cage, strengthening the product itself. GKLO contains crystalline hydrates, which emit crystallization liquid when heated. This allows you to prevent fire, when heated, the material extinguishes itself, lowering the temperature.

For example, an ordinary gypsum board that does not contain crystalline hydrates collapses after 20 minutes of exposure to an open flame; a heat-resistant GCR can withstand fire. The use of this refractory building material allows to increase the level of fire safety. The time limit of fire resistance and other characteristics are indicated in the quality certificate with which different trademarks accompany their goods. Each GKLO sheet is marked with a symbol consisting of a plate type code, a standard marking, an indication of the variety of sheet longitudinal edges and product dimensions in mm. Often, for ease of visualization indicators are listed in the table.

Advantages and disadvantages

Heat-resistant plasterboard sheets have many advantages.

- The material contains no toxic substances, which guarantees the ecological purity and safety of the material for human health.

- This material has good thermal insulation. This is especially noticeable in the cold season.

- Sheets are convenient to bend, cut, which provides ease of installation, saves time and effort in the production of construction work.

- It is possible to apply any finishing and decorative coatings (paint, wallpaper, ceramic tile) to the surface of the GKLO.

- Good sound insulation. This material perfectly absorbs noise.

- Affordable price. Heat-resistant material is more expensive than conventional plasterboard, but it is cheaper plastering work.

- Low weight sheets reduces the load on the structure.

It is convenient to combine drywall with other materials, creating arches, a variety of functional and decorative designs.

- Plasterboard can absorb excess moisture in the room and return it in a dry time ("breathe").

It is worth noting cons GKLO.

- Heat-resistant drywall is not recommended for use in rooms with high humidity. For such premises should be used GKLVO, which is well opposed not only to fire,but also moisture, thanks to a special impregnation.

- Gypsum plasterboards do not have high mechanical strength. Various fasteners (nails, screws, screws) do not hold well on them.

- The material is sensitive to various damages or dents. If you need to hang furniture on the wall of GKLO, it is worthwhile to additionally reinforce it and use dowels designed specifically for gypsum boards.

Types and characteristics

There are 2 types of heat-resistant gypsum board on the modern Russian market: GKLVO and GKLO. GKLVO - gypsum plasterboard sheets. This is a combined building material that combines the moisture-resistant properties of GKLV and heat-resistant GKLO. It is used in industrial or domestic premises with a high level of humidity. The color of the front side of the cardboard is green, marked in strictly red. GKLO - plasterboard refractory sheets. This heat resistant plasterboard has a high level of fire resistance. It is advisable to use it for interior trim of rooms with normal or low humidity.

Specifications

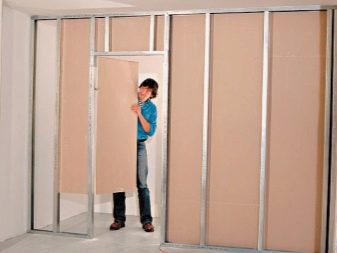

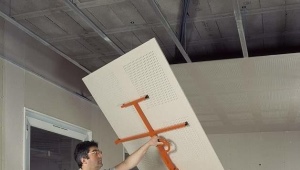

The most important parameters that you should pay attention to when choosing refractory drywall - fire resistance and sheet weight. These characteristics are determined by GOST and must be indicated in the product quality certificate. GKLO is used for wall cladding and ceiling. Weight plays a big role. For walls, sheets having a greater thickness (standard 12.5 mm) are used.

For covering the ceilings use lighter versions of the product in order to reduce the load on the structure.

The limit of fire resistance shows at what duration of the impact of an open fire on the material begins its destruction. The amount of fire resistance is indicated by numbers. The higher it is, the more refractory and quality the lining is. The number indicates the time period of resistance of building materials to the flame. For example, GKLO 25 will begin to collapse under the influence of fire in 25 minutes.

The most durable version of GKLO 55 resists fire for almost an hour. Another important fire parameter is the category of flammability of the material. According to GOST No30244, fire-resistant drywall belongs to the group G-1.

This means the following:

- t flue gases GKLO less than 135 oc;

- the degree of damage to the product in length in case of fire is not more than 65%;

- the level of destruction of the product during a fire is less than 20% by weight;

- the sheet does not burn on its own.

- standard dimensions of the sheet GKLO 150-300 cm x 120 cm, thickness 1.25 and 1.5 cm;

- gray color with red marking.

Designation of the types of edges of the sheet GKLO:

- PC - straight;

- PLC - semicircular;

- PLUK - semicircular refined;

- CC - refined from the front.

In the production of GKLO cover flame retardants, to withstand the effects of high temperatures and does not ignite. Sheets only char, but do not burn. For the manufacture of sheets used reinforced gypsum, the last special heat treatment. This significantly increases the durability of the material during exposure to high temperatures.

For physical and hygienic properties, it is excellent for residential use. It can be used to decorate the premises of apartment buildings, private buildings, industrial facilities. Its properties allow you to make different shapes out of it, thereby decorating the surfaces of walls and ceilings. In addition to the arches of drywall, you can cut a variety of shapes.For example, in addition to geometric shapes, it is possible to cut out individual flowers, butterflies, and abstract motifs, decorating the ceiling space with them.

It can be given a wavy, curved shape. In this material, you can mount different lights, including lamps on pendants and models of the built-in type. They will not harm, not destroy it. Convenience is the fact that if necessary GCR is allowed to tint.

Manufacturers

In the domestic market, the following firms have recommended themselves well:

- Knauf;

- Giprok;

- Velma;

- Lafarge.

Their products are reliable, drywall is produced in compliance with the requirements of GOST, it is tested.

Application

The use of non-combustible drywall is quite wide. The material is used for the implementation of various works. It is used for interior decoration in buildings for which high fire requirements for finishing materials are defined. These include boilers, boilers, industrial premises, as well as public buildings that have high throughput.

In addition, this drywall is applicable to:

- arrangement of walls and bearing elements in schools, kindergartens and other educational institutions;

- the lining of wooden buildings, country houses, garages to prevent the likelihood of fire;

- the formation of ducts in the construction of ventilation systems and the laying of electrical cable in domestic and industrial premises;

- installation of interior partitions and suspended ceilings;

- the construction of chimneys, chimneys, fireplace portals;

- covering of walls and ceilings of bathrooms, utility rooms in saunas, baths.

In addition, they use this moisture-resistant material when carrying out repair work in children's rooms. The area of use of fire-resistant gypsum is quite extensive. This non-flammable material is practical to install and helps protect the premises from fire. It is important to thoroughly choose high-quality material and follow simple rules for installation of a gklo.

Installation of stretch ceiling plasterboard, see the following video.