How and what is the right way to cut drywall?

To install drywall requires the creation of parts with different configurations. At home, the owner of the apartment makes such decisions infrequently, therefore, it is impractical to purchase expensive electric saws. For cutting suitable tools general profile.

Selection of tools

At the industrial enterprises drywall is required in large volumes. Therefore, for cutting GKL developed special hardware installation. At home, everything is much simpler - in the course are the improvised tools that exist in each apartment.

So that at the end of the work you do not need to extrude every detail, it is necessary to cut the drywall as even as possible. To achieve this goal on the plaster mark the mark with a pencil and a tape measure. If the latter is not among the tools or the length of the drywall is more than 2.5 m, then the surface can be marked out thanks to the metal profile.

Several tools can cope with the cutting of drywall:

- cutter (hacksaw) for metal or wood;

- jigsaw;

- construction knife with replaceable blades;

- electric drill.

The latter tool is suitable for drilling even circles of small diameter. As the radius increases, feather drills or rounded saws must be used.

Electric drill is suitable for creating holes under the core of the door locks. A regular handsaw on metal or wood is capable of sawing drywall. The tool has a thin blade with a frequent row of teeth. There is a minimum distance between sharp ridges to prevent chipping.

Before starting work, it is recommended to place the drywall in a horizontal position on any stable support.

Dense sheets of drywall can be cut with a construction knife. The device is convenient to operate due to a double-sided sharp blade.Over time, the core becomes blunt, however, manufacturers put several additional elements inside. Therefore, if necessary, the blade can be easily changed to a new one.

For cutting with a construction knife, drywall is required to mark and put a metal ruler along the pencil mark. While holding the profile, make a cut with a knife. If the plaster is of a small thickness, it is possible to replace the construction knife with a stationery one.

To finish the room with a higher humidity coefficient, they take moisture-resistant drywall, which consists of antiseptic elements. They give the surface of gypsum a greenish tint. Additional components do not affect the density indicator, so cutting moisture-resistant drywall is possible with similar tools for cutting the classic version.

Proper slicing

Properly cut drywall will help a few simple rules:

- Working with gypsum requires resorting to security measures. Even a dotted incision or small rip crumbles the material. This produces dust that is dangerous to the body. Keep your eyes and lungs safe with glasses and a respiratory mask.

- It does not matter which side to cut the drywall. However, experts recommend starting with the surface that will be in contact with the wall or ceiling.

- Cutting the profile leaves uneven edges. It is not worth spending time aligning them, because subsequently flaws are hidden with drywall.

- Cut sheets of drywall should be in dry areas. In conditions of high humidity, the material quickly swells and becomes unsuitable for use even after drying.

- Competently sawn flexible drywall can be on a stable surface with a smooth relief.

The lining material itself consists of two layers of cardboard. They are covered with a thick plaster layer. This structure provides fire resistance and strength by increasing the density. Consequently, to realize a point slice, it is sufficient to deepen the incision several times with a sharp blade with neat movements from top to bottom. After that, the sheet must be broken along the cut line. In this case, it is important to keep the drywall in one position, not allowing the blade to move when cutting the cardboard layer.

Such actions are effective when cutting drywall, leaning against the surface of the wall. You can hold a layer of material with your foot.

On the wall

If necessary, to finish with a plasterboard material a window opening or a wall corner, cutting the gypsum board is carried out directly on the bearing surface. In this case, the plaster edge coincides with the edge of the wall. To create such a model using a piece of drywall larger than required. The material is attached to the surface of the wall, after which excess elements are cut off from the plaster.

Performing the procedure requires a secure attachment to the bearing surface. Cutting starts from the side of the drywall sheet, which fits tightly to the support. While pressing down on an unnecessary part, it is necessary to hold along the marked line several times. After that, the remaining elements of the cut are cut off on the reverse side.

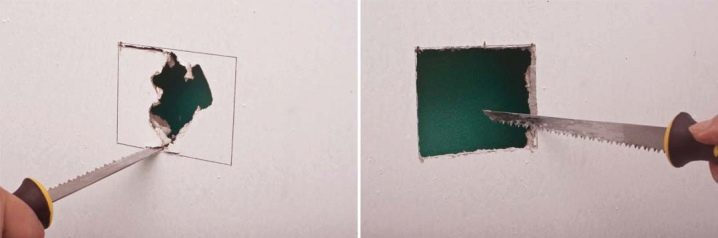

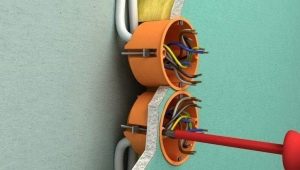

Holes for lights and sockets

Specialists cut out the holes for sockets or lamps after installing and fixing the drywall. For beginners, you can do without prior attachment. To this end, you must first accurately calculate the position and parameters of the future hole.

It is important to remember that the lumen itself is a small form, which subsequently hides an additional plastic frame (for decorating the outlet or the base of the lamp).

All calculations must be applied from the reverse surface of the drywall. For the cutting itself, you need a screwdriver or drill. The tool must have additional circular nozzles with fine serrated blades. In the absence of a gun fit a classic handsaw. Holes are uneven, but correspond to the calculated parameters. All flaws are covered by a canvas.

Uneven line

When cutting drywall in the form of a wavy curved line can not do a regular hacksaw or construction knife. During their operation, smooth bends are uneven. To achieve a perfectly flat surface, you must purchase or rent a jigsaw with fine blades. At the same time the tool creates a huge amount of gypsum dust. Because of this, it is necessary to take care of the individual protection of the eyes and lungs.

At the end of the manufacture of parallel parts should be the bending of drywall elements. The first step is to create a rectangular sheet of plaster material corresponding to the size of the space between the straight parts. Correctly measure the pitch will help centimeter roulette. Thanks to its flexibility, it is possible to measure the arched length of a bend.

The front surface has a higher density compared with the wrong side of drywall. Because of this, the arcuate detail is curved in such a way that the back surface of the material is stretched. To bend the future arch exactly, you can resort to the template. The latter is made of plywood.

Then proceed according to the step by step instructions:

- On one side, the arc is bent with a needle roller. At the same time it is necessary to constantly press on the drywall. Needle roller will penetrate into the plaster material to 5 mm.

- At the end of the work, the surface of the drywall is moistened with water until softened. This stage requires a long time and patience. As the drywall swells, it is necessary to bend gradually.

- As soon as the item is tightly settled in a template form, it is fixed until it is completely dry.

For sloping elements with a radius of more than 40 cm, the bend is not so steep, thereby making the part does not require additional wetting. It is possible to realize identical elements of the wavy type with the help of transverse cuts. It turns out the accordion that you want to fix the primer.When bending drywall all the gaps need to be puttied.

For high arches, it is not possible to bend plaster material. When installing such an element with scissors, they create triangular cuts in increments of up to 10 cm. The distance depends on the bending steepness.

A circle

It is easy to achieve a perfectly round hole with a drill with special drills. The nozzle is perpendicularly pressed against the surface of drywall. Clicking on the trigger, begin to drill a hole.

To create decorative holes of large diameter or rounded parts (for example, wavy elements), the drill is not capable. The hacksaw will easily cope with a similar task by a method of section of internal elements. To do this, cut a line and insert a canvas with pencil markings. Then it is cut according to the markup.

It is inconvenient to work with a hacksaw with drywall on the floor, so it’s best to put a sheet of plasterboard on the table. And plastering will have to be laid in such a way that the part to be cut is outside the table top.

Specialists can cut with a regular knife, then beating a circle with a sharp jerk. However, in the absence of professional skills in working with gypsum plasterboard, an uneven break with jagged chipped edges is formed.

In a straight line

Before you begin, you need to make measurements in the room, so as not to be mistaken when cutting parts. A simple pencil will help mark the cut lines. A marker or pen is best not to use. Corrosive ink leaves traces appearing through the layer of putty.

When applying the main lines, you must first make the same marks at the top and bottom of the sheet. After that, attach a level or a metal ruler to the points, on which a straight line is drawn.

Upon completion of the calculations and applying the appropriate markup, the drywall is placed on a parallel floor surface. For cutting, it is more convenient to use a construction knife, since the sharp blade can be adaptively adjusted at work. It should be remembered that the length of the tip should not exceed the thickness of the drywall. It is recommended to make an incision in a metal ruler that fits over the pencil marking. To create a flat line it is required to additionally spend 3 times on the cut with a tool.

In case of placing a drywall formation on the table, it is necessary to move the gypsum so that the detachable part does not come into contact with the tabletop surface.As soon as the cut is deep enough, you should pick up the edges of the drywall and break it along the line with a sharp movement. For the final cut from the opposite side, an additional cut is made with a construction knife.

When sawing plasterboard on the floor after additional movements plasterboard product must be placed in a vertical position. The cut-out part must be separated from the unnecessary by gentle shocks on the front side (make a break). After that, the inseparable fragments are cut with a blade.

It is important to remember that you cannot use a circular saw for cutting drywall. Small teeth rotating at high speed produce a dense column of dust. The solid particles are deposited in the lungs and on the mechanical parts of the instrument, causing damage to both the person and the inside of the circular saw.

The letter "G"

Curved with the letter “G”, the form of gypsum board is used for facing a door or window opening, as well as when creating any corner model.

The work begins with the calculations and marking the line with a pencil. To implement, you can use a hacksaw, if you do not have a specially notched saw blade on the drywall. Gypsum is a soft malleable material that does not create problems when cutting.

The tool must cut a short part. Long cut out according to the method of "straight line".

Edge processing

Work does not end on the cutting of drywall. Sharp and uneven edges need alignment. Handle nicks and chips can be with sandpaper.

It is recommended to level with gentle movements to achieve a smooth surface. At the end of the preparatory stage, they carry out fasciation. Two thirds of the thickness of the drywall sheet must be cut from each edge. Further, at a 45 degree angle, the chamfer is cut by a plane. If you do not have the right tool, you can use a regular knife.

After sanding the edges, you must install the drywall in the desired position. However, at this stage, there are numerous gaps that require putty. Once the material is completely dry, the plasterboard surface is primed for additional reinforcement. Then proceed to painting or glue wallpaper.

Useful tips

To eliminate the unpleasant consequences of self-cutting drywall, it is recommended to listen to the advice of professionals:

- When cutting and installing a large area drywall alone, it is inconvenient to lift it and at the same time adjust it with a hammer. It is recommended to put the bar on the floor and use it to break off the drywall exactly along the marked line.

- Most craftsmen are wondering which side to cut drywall. The material is not picky and breaks well from the back and from the front side.

- It is necessary to carry out the cutting of drywall immediately. In no case after installation, because it is wrong to cut or break a soft product.

- When working with circular cutting drywall it is possible to do without compasses. To create a suitable circle will help the plates, glasses or covers from the pots.

- Bulgarian is not suitable for cutting drywall. The tool creates a cloud of dust that irritates the mucous membranes and produces noise. Also, the Bulgarian requires additional means of protection and skills of working with electric devices. It is safer to cut the plasterboard with a stationery knife and a hammer.

- To facilitate the work with drywall can electric jigsaw, having a hard blade with small teeth. The tool is much better suited for creating ornate decorative elements.configuration. For one time, experts recommend not to purchase, but to rent the device from any construction company. So it will be much cheaper.

In addition to the recommendations on the work, it is important to remember the fragility of the material. In drywall can not cut a complex image with thin elements. A fragile structure that collapses quickly even when reinforced with cement mortar or primer. Drywall sheet will be durable only with large lines and when creating wide parts.

To learn how to cut the drywall yourself, see the next video.