Features and subtleties of leveling a concrete floor

Equal floor is not only an indicator of quality repair, but provides a long service life of all types of coatings. Finishing laying floors should be carried out exclusively on a flat and smooth surface. In apartments, houses, offices and garages, the basis for the flooring is presented in the form of concrete slabs, which are not even in their structure, they may be defective and often inclined. Therefore, all construction work begins with the alignment of the concrete surface. There are many ways and technologies for this.

Special features

Owners of newly acquired apartments, as well as those who have housing that requires major repairs, first of all, they need to resolve the issue of leveling the concrete floor. Only after the base for laying the finishing coating becomes even, will it be possible to take up its further decoration and decoration.If it is not leveled, then the new floor will not last long, in addition, in the future there will be problems with the installation of doors, the arrangement of furniture and equipment.

Concrete floor is not ideal, so often in the process of its operation, small chips, cracks, bumps and roughness may appear. In addition, there are such significant defects as pits, flows, bevels in the direction or differences in height.

Depending on the degree of unevenness of the surface and the number of holes, an appropriate method of leveling the concrete is selected, and construction work is carried out.

If the apartment has large level drops, then use a dry screed, which not only perfectly levels, but also provides good thermal and sound insulation. Effectively to eliminate the flaws will help and liquid solution prepared on the basis of cement. A good option is also considered to be a self-leveling mixture, it is evenly distributed over the entire surface, as a result of which any degrees of curvature are removed. In order to "hide" small cracks, suitable putty. Usually the leveling process is as follows: the concrete surface is thoroughly cleaned from grease, paint and dust, putty is applied,then apply the most suitable of the ways to eliminate irregularities.

Device

The floor is the most important floor in the house. As a rule, its base is represented by concrete, which is made of cement and various fillers. In order for concrete to meet all operational requirements, water-repellent components and accelerators are also added to it. Such a base is characterized by increased resistance to chemical and mechanical stress, as well as durability.

To ensure that the concrete surface reliably lasts a long time, during its installation it is required to comply with all technological processes.

There are two types of overlap: the floor laid on concrete slabs and beams, as well as concrete pouring, which is carried out on the ground. In addition, the coating can be made with the underground or made monolithic.

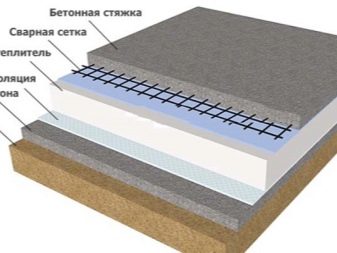

The latter is the most popular and consists of the following layers:

- priming;

- clean sand;

- roughing screed;

- steam and waterproofing;

- cement casting;

- topcoat.

Before starting work, dismantle the old floor and prepare the base.If the surface is not damaged, you can immediately begin the alignment. In a private house, when performing pouring on the ground, you will first need to do drainage works. To do this, a layer of sand with a thickness of at least 5 cm is placed under the base, then a layer of stone or expanded clay is poured, its height should not exceed 10 cm.

For the best surface tamping, a special active machine is used. To further protect the surface from damage, it is impregnated with polystyrene concrete.

The draft layer is the basis for the installation of waterproofing. It is placed on top of expanded clay or stone and covered with a special film. Often, instead of a rough tie, ordinary cement mortar is used, which cannot be covered.

When pouring concrete required mandatory installation of insulation. It can be performed using bitumen, roofing material or membrane. Waterproofing should be laid tightly, excluding the penetration of moisture.

In addition, you will need and insulation, for which use:

- polystyrene foam;

- perlite;

- mineral wool;

- plywood sheets;

- Styrofoam.

After installing all types of insulation perform cement screed and proceed to the installation of metal fittings.A wire with a diameter of no more than 3 mm will be suitable for living rooms, and you can use a grid with 5 × 5 cm cells on the balcony. In the event that an installation of a “warm floor” system is planned in the apartment, polyurethane is placed between the walls and the screed. As a result, a small gap is formed, which will prevent the floor from heating and protect the concrete from cracking.

When all of the above steps have been completed, you can proceed to a clean pouring of the base.

The layer of mortar should be distributed evenly across the horizontal surface. To do all this right, it is recommended to set up beacons. The casting mixture is made of rubble, sand and cement, while the sand must be used river, clay impurities in the solution are not allowed.

The mixture is recommended to distribute, starting from the opposite door angle. After the surface is completely dry, it will only remain to secure the topcoat, this is best done with tile adhesive.

What is the best level?

Many are concerned about the question of what materials and methods of leveling are considered the most effective and best. To select the appropriate option, it is necessary to calculate the surface area and evaluate its defects.For example, the cheapest type for leveling concrete floors is cement mortar. It is preferred in the event that you need to put a thick layer of finishes for large rooms.

Often craftsmen use tile glue for these works, but it is difficult to apply it, therefore, in order to level the floor by this method, experience is required. A bulk mix is also considered a good way to eliminate irregularities on the surface; it not only speeds up construction work, but also serves as an excellent waterproofing.

If we consider the leveling materials for the time of their filling and drying, then there is no difference in them. All solutions and mixtures are applied strictly in compliance with building technologies, therefore it is impossible to speed up this process.

Ways and stages of work

To date, there are many methods for leveling a concrete floor, the most popular and widely used of them is the use of self-leveling mixture. As a rule, this option is chosen in the case when the base has minor flaws and the height of the levels does not exceed 3 cm.

The main advantages of this method include:

- At the end of the work, the surface of the floor looks perfect and noble.

- Affordable cost. When leveling does not require additional costs for the purchase of materials for laying.

- Fill technology is simple.

- The mixture dries quickly and reliably serves for many years.

To level the floor with a self-leveling mortar, it is first necessary to prepare the surface and coat it with a primer. Then between the walls and the floor paste construction tape, and mix all the components of the mixture.

It should have a uniform and spongy consistency, so it is recommended to perform stirring not manually, but using a drill with a special nozzle. The finished solution is evenly distributed on the base, and leveled with a needle roller. Work must be done very quickly, as the base quickly hardens.

A cement screed will also help to level the concrete floor. Usually, this option is recommended when the irregularities in the rooms exceed 3 cm. With cement mortar, all types of irregularities can be eliminated, besides, it serves as an excellent basis for the final coating.The only drawback of this alignment is the difficulty of implementation, and the installation process takes a lot of time.

Works are carried out as follows:

- A primer is applied to the prepared substrate. This is especially important to do in the kitchen and in the bathroom, since in these rooms the humidity is always increased.

- Installation of beacons is in progress.

- An adhesive tape is glued between the joints of the walls and the floor.

- Preparing the mixture.

- Cover the concrete with mortar, and make the alignment in a circular motion.

Sometimes there are rooms in which the level of irregularities exceeds 10 cm. In this situation, only a dry screed can cope with the alignment. It is easy to use, does not require drying, and also provides the base with additional thermal insulation. Dry screed is suitable for all types of coatings, but most often it is chosen for a wooden floor.

The alignment is carried out as follows:

- Concrete floor is cleaned, if there are cracks, they need to putty.

- Apply primer.

- Exposed level.

- Claydite or polystyrene foam is filled.

- Sheet of chipboard or plywood are laid, the joints between them are covered with white glue.

Although this leveling method is characterized by positive aspects, its implementation requires a large consumption of building material. In addition, upon completion of the process, the surface of the floor covering will rise significantly, resulting in a room reduction. Therefore, laying lag on the surface can be an excellent alternative to dry screed.

Surface preparation

The first step in leveling the concrete floor is to prepare its base. In order for the work to be done correctly and efficiently, it is necessary to act in stages. Therefore, the first look at the surface of the old coating, and if it has deformations and defects, it is dismantled. This can be done using a punch. In addition, you will need to carefully seal all the bumps and cracks in the concrete.

To better understand the degree of irregularities, it is recommended to level out the levels in the lower part of the room, then prepare the mixture and fill it with gaps.

The composition of the solution may be different, for this is well suited as a gypsum "porridge", so the cement mixture. To avoid a curved surface, grouting is done after pouring.After this stage, choose the appropriate type of screed, and cover it with the base. When the mixture is completely dry, it is covered with plywood, you can also level the finish floor and OSB panels.

By the beacons

Uneven flooring is a common problem in many homes and apartments. To correct its defects, it is possible to fill the surface of the base with concrete or sand concrete. If construction work is done by hand, then it is recommended to use a special equalizer, it is easy to operate and does not require practical experience in application. Whichever leveling method is chosen, it will not do without the installation of beacons, they are usually made of gypsum or cement mixtures.

The process of mounting beacons is as follows:

- Determine the minimum thickness of the layer, which is needed for equalization. To do this, use the laser level, and make markup lines.

- Preparing putty. All its components are taken in strict proportion.

- Installation begins from the wall. Lighthouses are set at a distance of 15-20 cm, they need to be puttied and fixed.

- After the putty is frozen, the surface is checked and excess material is removed.To make the base smooth, it needs to be sanded, and a grinding machine is suitable for this.

The most important thing is that during the installation there should not be left blank areas, but if there are such, they are necessarily covered with a putty and leveled. After the base is completely dry, it is possible to proceed with immediate alignment.

Professional Tips

It is difficult to level the concrete floor independently, so if homeowners decide to do it themselves, then they need to take into account a lot of nuances. Experienced masters recommend that when performing this type of work always take into account the temperature mode of the room, preventing the appearance of drafts. Mixture for pouring must be thoroughly mixed, as the formed lumps can spoil the whole process. To simplify the mixing of the solution, it is best to use a drill with a nozzle or a small concrete mixer.

In addition, we must not forget to do the quality control of the fill using the level.

If you adhere to all of the above recommendations, then the floor will surely turn out to be even and smooth, and the decorative coating will last for many years.

In the video below you can see the easiest way to level the floor.